Wire Wrapped Drum Magnet Benefits

By Paul Fears | 14 June 2021

Robust and with a high-intensity magnetic field: the Wire Wrapped Drum Magnet bridges the gap between standard Neodymium Rare Earth Drum Magnets and magnetically powerful Rare Earth Roll Magnetic Separators.

Drum Magnet Technology

A permanent Drum Magnet features a stationary magnetic element mounted inside a rotating non-magnetic shell. In operation, the magnetic element projects a magnetic field above the surface of the shell, enabling the attraction and separation of magnetic particles from dry non-magnetics. The hardwearing stainless or manganese steel, non-magnetic shell has excellent wear characteristics.

- Technical Product Information: Permanent Drum Magnets

Rare Earth Roll Technology

A Rare Earth Roll Magnetic Separator comprises of a thin belt and a permanent, high-intensity neodymium head pulley. Material feeds, via the belt, into the intense magnetic field of the head roll where weakly and para magnetic particles are attracted and separated. The weak point is the thin belt, which can easily damage if exposed to strong magnetic particles such as tramp and fine iron.

- Technical Product Information: Rare Earth Roll Magnetic Separator

The Wire Wrapped Drum Magnet

The critical distance (i.e. between the material and the magnetic element) is greater on a Drum Magnet than a Rare Earth Roll Magnetic Separator. As magnetic fields diminish in intensity over distance, all magnetic separator designs focus on limiting that ‘critical distance’.

On a Drum Magnet the ‘critical distance’ is composed of an air-gap between the surface of the stationary magnetic element and the under surface of the shell, as well as the thickness of the shell. For a Rare Earth Roll Magnetic Separator, the material to magnetic element distance is only the thickness of the belt. Hence, the magnetic intensity experienced by a susceptible particle is always greater on a Rare Earth Roll Magnetic Separator.

However, although more arduous applications often require a higher magnetic intensity (such as foundries, abrasives, silica sand, etc.), the wear limitations of the Rare Earth Magnetic Roll belt preclude the technology from extensive use.

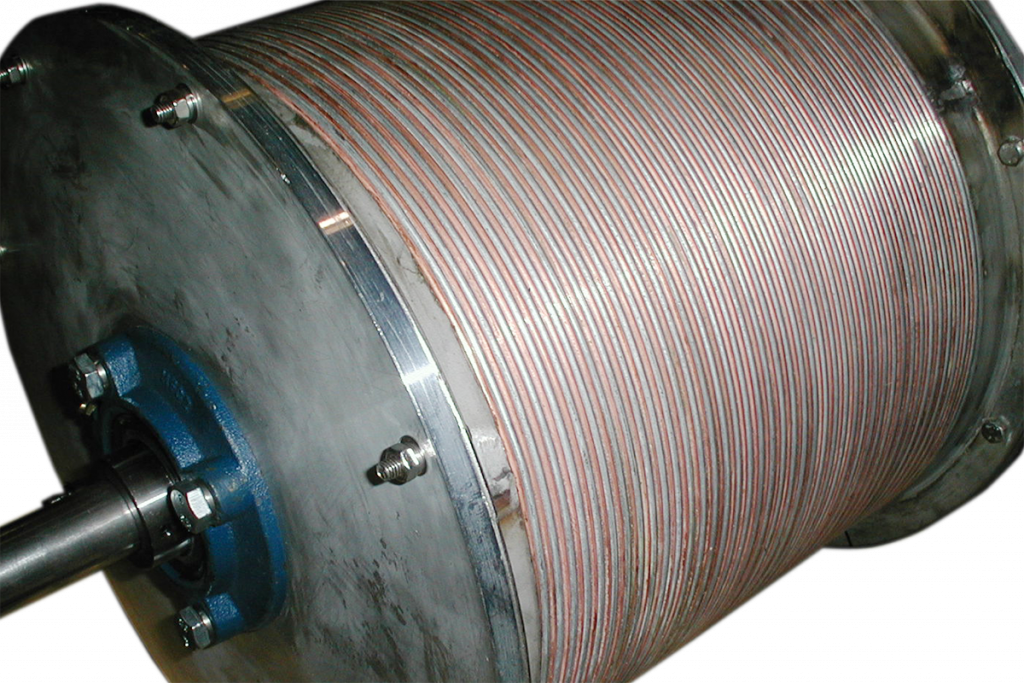

The solution was to boost the magnetic field on the surface of the Drum Magnet. As the permanent magnetic element already produced the highest possible magnetic field and the ‘critical distance’ had been minimised as much as possible, the only way to boost the field was by modifying the shell.

Subsequent design work identified that when wrapping the shell in a mix of steel and non-magnetic metal wire, the magnetic field intensifies on the edges of the steel wire. The amount of boosted magnetic field is related to the diameter of the Drum Magnet, but is nominally at least 50% higher than the magnetic field on the surface of a standard stainless steel shell. Although the magnetic field intensity remains less than that seen on a Rare Earth Roll Magnetic Separator, the boosted field enables the separation of weakly and para magnetic particles and minerals. Hence, the Wire Wrapped Drum Magnet provides a viable, popular, robust and hardwearing solution for more arduous applications.

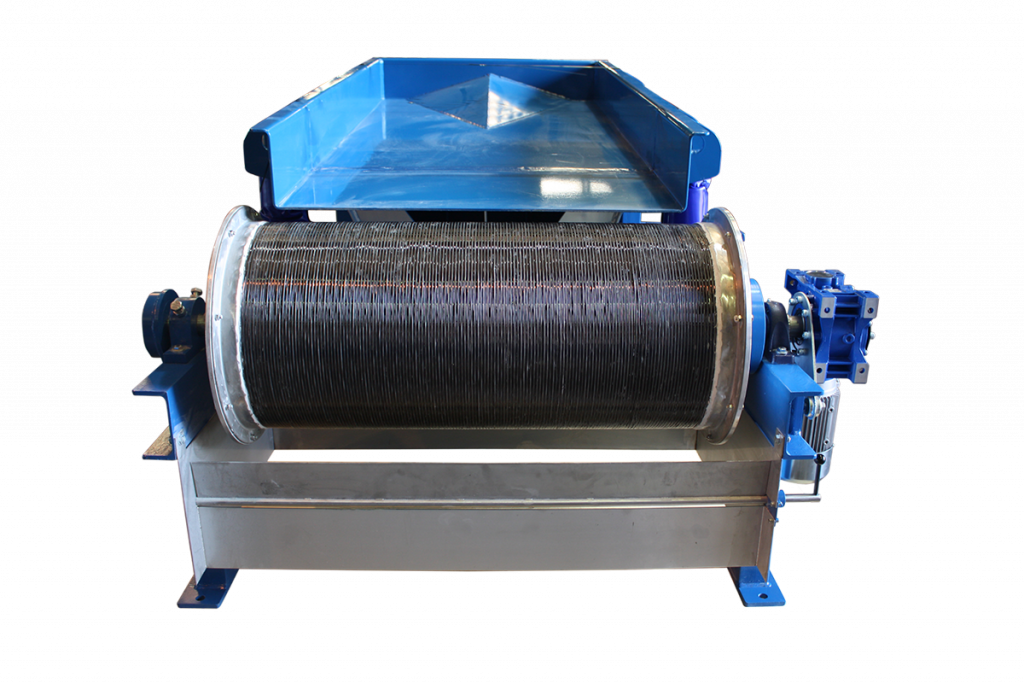

Wire Wrapped Drum Magnet Applications

The increased magnetic intensity of the Wire Wrapped Drum Magnet enables the separation of fine iron and weakly or para magnetic particles and minerals as found in non-metallic mineral deposits such as silica sand, chromite in foundry sands, abrasives such as corundum and alumina, and for recycling applications. The optimum particle size of the fine granular material is between 70µ and 2mm.

Specifications of the Wire Wrapped Drum Magnet

The design criteria of the Wire Wrapped Drum Magnet enable the manufacture of a wide range of drum diameters up to approximately 600mm, and with drum widths up to 1500mm. Larger diameter Drum Magnets have higher capacities.

Laboratory tests at Bunting’s Customer Experience Centre in Redditch UK determine the optimum size and respective capacity for a given application.

Related Technical Articles

Magnetic Separators – Mineral Processing Laboratory

Bunting-Redditch has one of the most comprehensive magnetic separation mineral processing testing laboratories in the world. Their Laboratory Technicians have decades of experience in mineral processing. Controlled tests ensure that the most suitable and cost-effective machinery is recommended for each application. The laboratory is equipment with a wide range of equipment including:

- Smaller scaled versions of industrial Magnetic Separators. This equipment is used to accurately scale up to industrial capacities and calculate performance guarantees;

- X-Ray Fluorescence and X-Ray Diffraction analysis are available for chemical assay and mineralogical identification to aid the development of a viable process route for each application;

For further information on our range of magnetic separation equipment designed for purifying ceramics and non-metallic minerals, or to arrange sample tests in our laboratory, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

To keep up to date with our news and technical reports, please follow us on social media