Customer Experience Centre for Separation and Detection

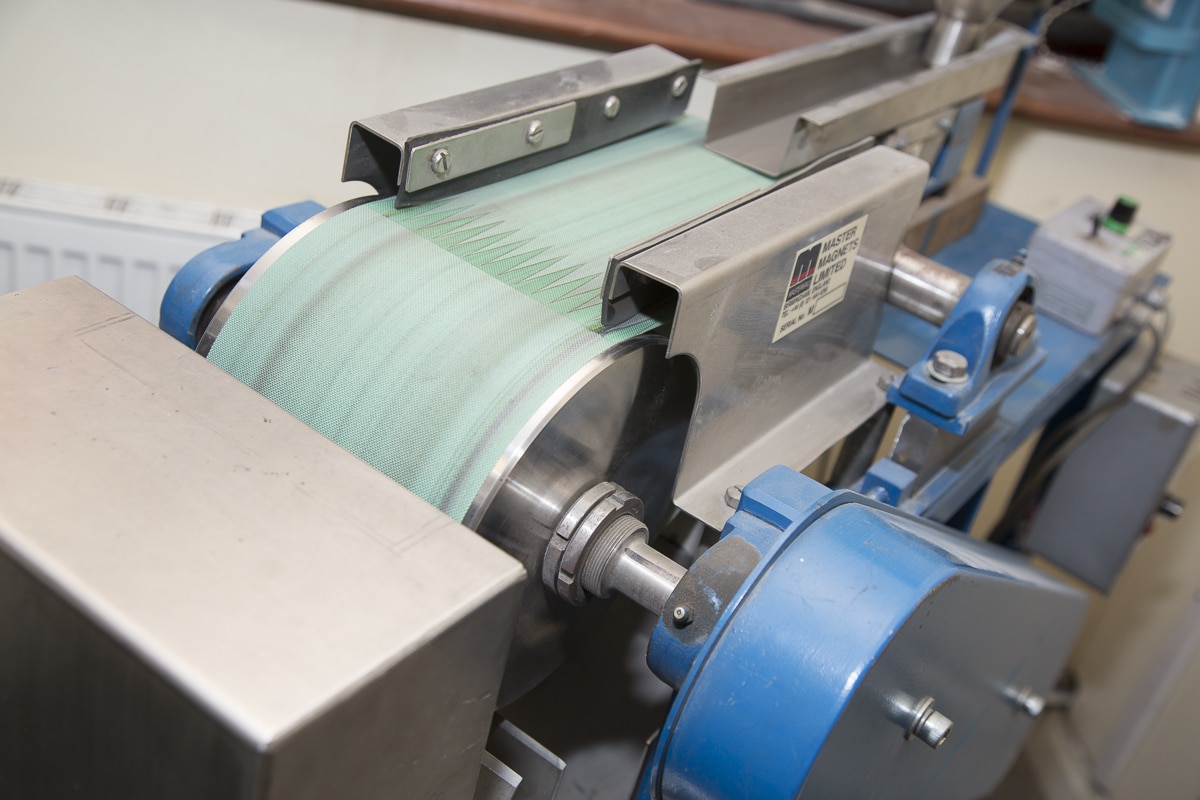

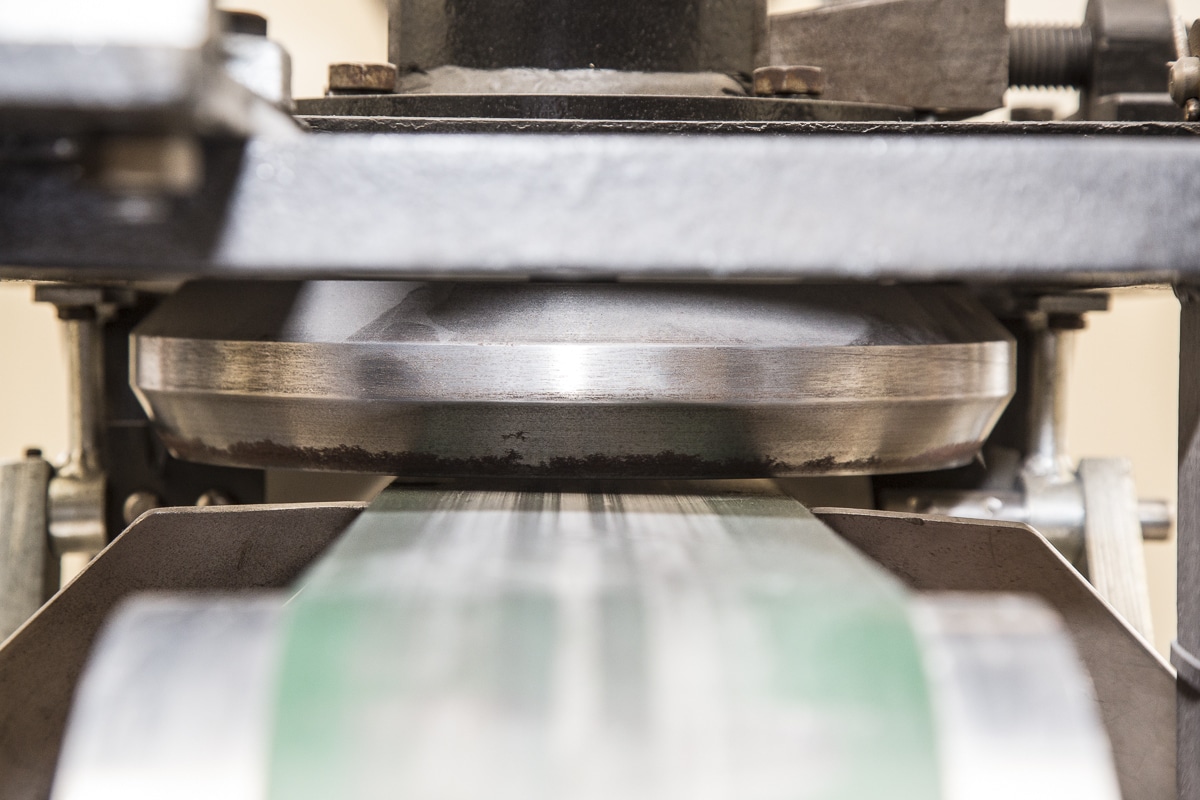

Bunting’s Redditch manufacturing facility is home to one of the world’s most complete laboratories for Magnetic Separation and Metal Detection equipment. Mineral processing, mining and recycling companies from across the world send samples of materials for controlled tests by experienced technicians in Bunting’s Customer Experience Centre for separation and detection. Such tests enable companies to assess the feasibility of projects and confirm the separation and detection abilities of recommended Bunting equipment.

The range of laboratory-scale high-intensity Magnetic Separators include:

Dry Mineral Processing:

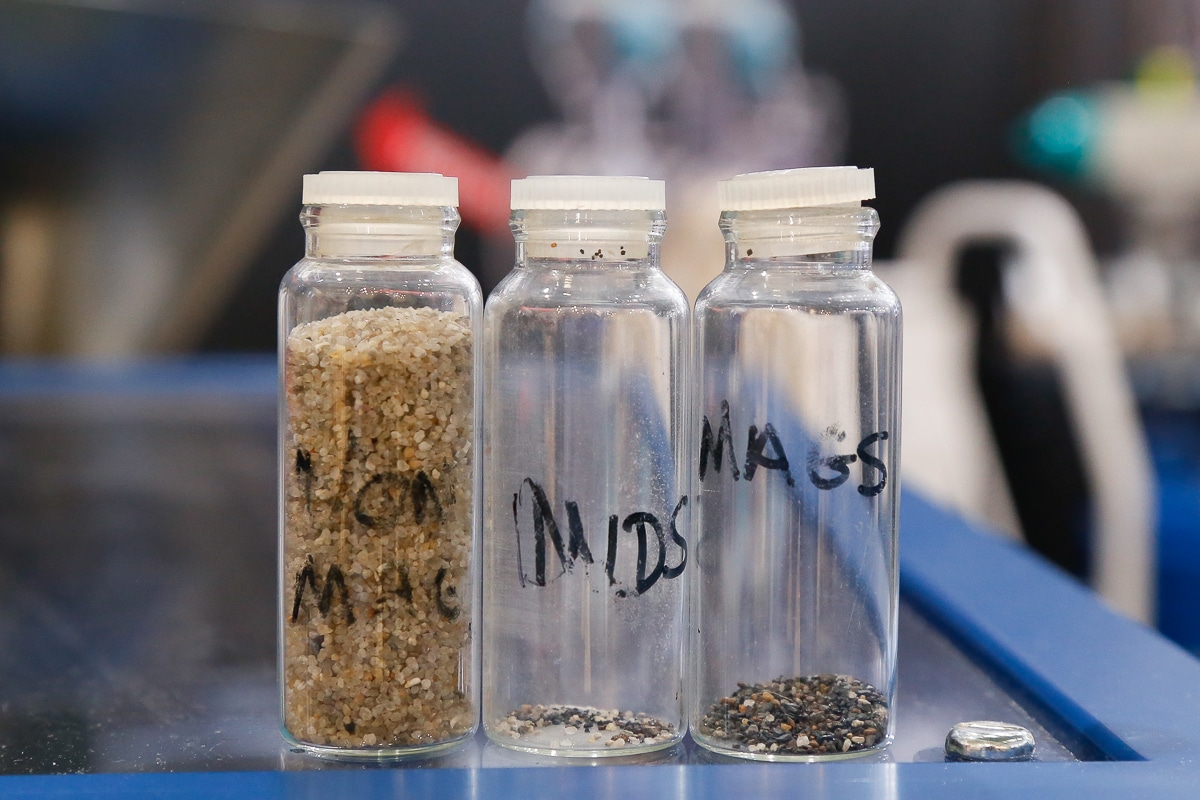

Bunting Laboratory Technicians conduct tests to determine the optimum solution for any given separation objective. This includes material recovery (either minerals or secondary metals) or increasing product purity. Tests form the basis for equipment recommendations and performance guarantees. When practically possible, customers are welcomed to participate and witness the tests.

Laboratory tests can include comprehensive chemical analysis using an X-Ray Fluorescence (XRF) Analyser. This enables the analysis of metal, mineral and soil samples by identifying elements such as Mg, Al, Si, P, S, Fe and is also capable of precious metal and rare earth element analysis. Using the XRF enables our technicians to make detailed and accurate recommendations on magnetic separation to reach your requirements and propose process flowsheet options to the customer.

In addition, Bunting have established a working association with the Centre for Critical and Strategic Metals at the University of Birmingham. This link provides access to an extensive range of mineral processing and recycling facilities and additional expertise.

For more information on Bunting’s Customer Experience Centre for separation and detection or to discuss sending material for testing please contact sales.redditch@buntingmagnetics.com

Technical articles