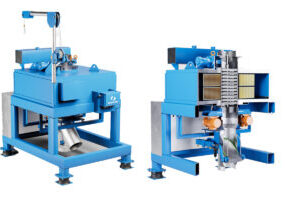

Description

Stainless Steel Separators (SSSC) are a revolutionary and patented ultra-high-intensity metal separator. Bunting has developed two different magnetic rolls capable of extracting large and heavy materials with weak magnetic properties (stainless steel up to 125mm). The magnetic rolls use the strongest permanent magnets presently available.

Model HISC – High-Intensity Separation Conveyor

Designed for the separation of small weakly magnetic particles (<20mm)

- Two standard pulley diameters – 100mm (4″) and 150mm (6″) diameters;

- Stainless frame discharge ends to prevent magnetic inducement from the extreme magnetic fields;

- Heavy-duty formed 5mm frames;

- The frame features forklift lifting slots for easy placement and relocation;

- Heavy-duty formed 5mm sideguards over the flexwall belt to seal off and contain the material flow;

- Tough urethane belt;

- Optional belt lengths for the addition of Permanent Overband Magnets or Plate Magnets to remove strongly magnetic materials;

- Optional variable frequency drive to optimise separation for belt speeds between 18 and 60 metres per minute;

Model SSSC – Stainless Steel Separation Conveyor

Developed to separate larger fragmented stainless steel (20 – 125mm)

- 200mm (8″) pulley diameter;

- Patent-pending magnetic core design;

- Unique high-intensity gauss grid design generates ultra-high magnetic forces;

- Stainless frame discharge ends to prevent magnetic inducement from the extreme magnetic fields;

- Heavy duty formed 5mm frames;

- The frame features forklift lifting slots for easy placement and relocation;

- Heavy duty formed 5mm sideguards over the flexwall belt to seal off and contain the material flow;

- Tough urethane belt;

Related Blogs

- High-Intensity Magnetic Separator Optimises Copper Recycling

- 3 Stainless Steel Magnetic Separators Sold

Operation

A controlled rate of material is fed via a vibratory feeder onto the belt of the Stainless Steel Separator (SSSC). The material is conveyed into the magnetic field produced by the Rare Earth Head Roll where even weakly magnetic material is attracted, held, deflected and then deposited underneath. Non-magnetic material is unaffected and follows its normal trajectory. An adjustable splitter enables highly precise adaptation to the separation of the two fractions – magnetically-susceptible and non-magnetics.

In some applications, a Permanent Overband Magnet or Plate Magnet is positioned over the conveyor to remove strongly magnetic or ferrous metals before entering the ultra-strong magnetic field.

Applications

HISC – High-Intensity Separation Conveyor

Designed for the separation of smaller weakly magnetic particles (<20mm)

- Removing weakly magnetic stainless steel in ICW and cable recycling operations to ensure copper purity;

- Granulated plastic waste to remove weakly magnetic stainless steel and fine ferrous metal;

- Stainless steel door mechanisms from shredded UPVC window frames;

- WEEE (electronic waste) to recover weakly magnetic stainless steel;

- Recovering Printed Circuit Boards (PCBs) from WEEE;

- Separating stainless steel needles from Medical Waste;

SSSC – Stainless Steel Separation Conveyor

Developed to separate larger fragmented stainless steel (20-125mm):

- Recovering larger fragmented stainless steel in Car Fragmentation Plants;

- Separating weakly magnetic metals from shredded White Goods;