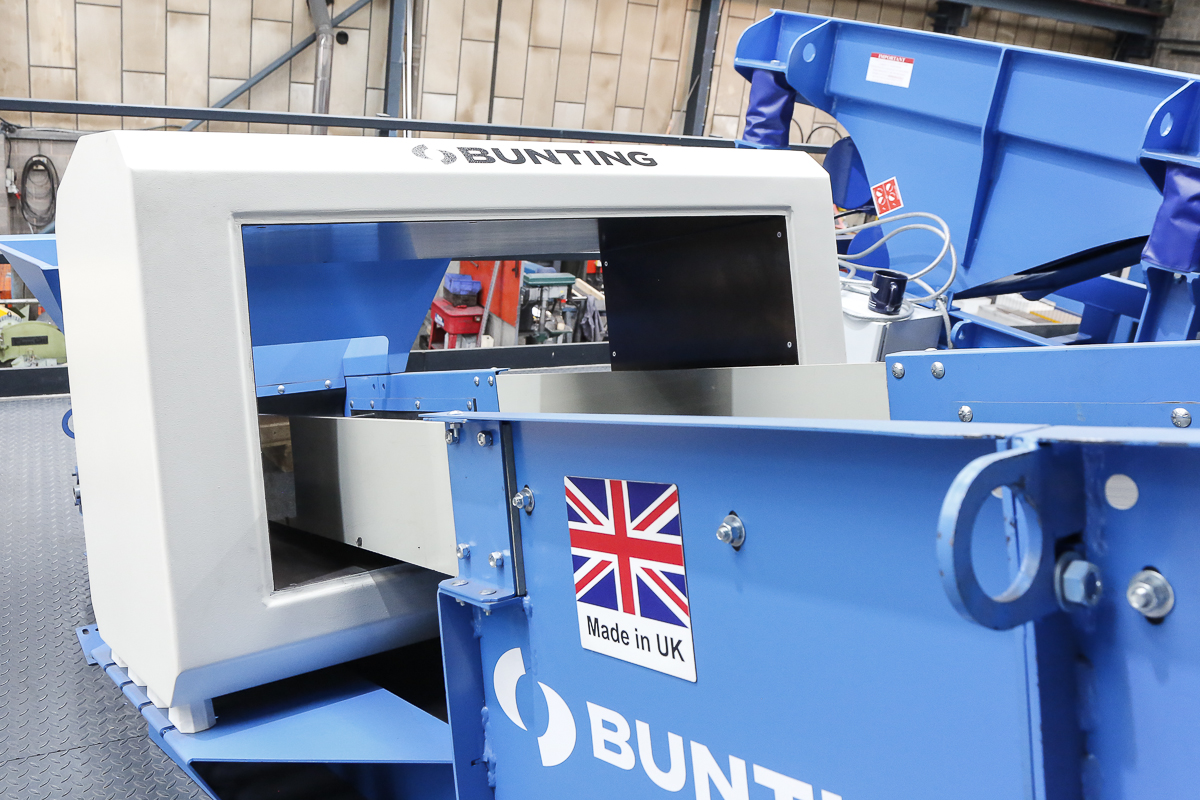

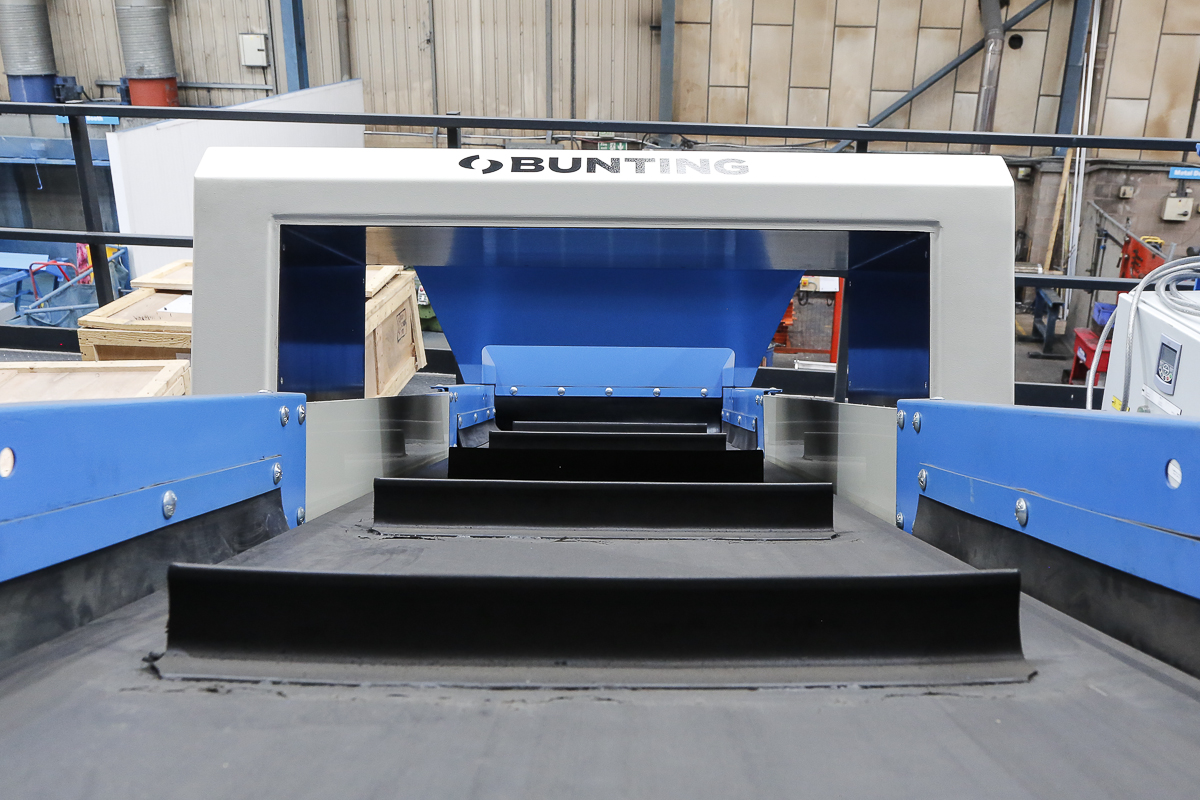

meTRON 05C

The closed tunnel type meTRON 05 C Metal Detector provides high-sensitivity detection in rough industrial environments including encapsulated or loose tramp metal present in conveyed, vibratory chutes, gravity-fed and material-slide transported materials. Once detected, the problematic metal is removed either manually or automatically, preventing damage to processing equipment. The meTRON 05 C typically protects equipment including grinders, crushers, mills, chippers, and shredders.

Description

The meTRON 05 C Metal Detector automatically and continuously detects tramp metal in non-metallic and non-conductive materials. This model features digital signal processing for optimum metal detection.

The meTRON 05 C is a tailored system solution using reliable conveying technology and selected accessories. There are a wide range of aperture sizes (through which the conveyor or chute feeds) to suit specific customer requirements. Additionally, different versions of the meTRON 05 C are available for specific locations (e.g. outdoors, high-temperatures, etc).

The meTRON 05 C features an integrated electronic control panel. This provides process and condition monitoring.

Operation

As with other Metal Detectors, on detecting any tramp metal, a signal is generated in the search coil and transmitted to the control unit. This signal is processed and used to control other circuits, which include the interlocking of the belt conveyor, operating audible or visual alarms, belt interlocking, marking devices or automatic rejection mechanisms.

Typical tramp metal detected includes:

- Washers

- Nails

- Screws

- Nuts and bolts

- Wire

- Swarf

Applications

The meTRON 05 C is designed as a high-sensitivity metal detector for rough industrial applications. Typical applications include plastics, textiles, wood, mining and quarrying, and recycling.