Description

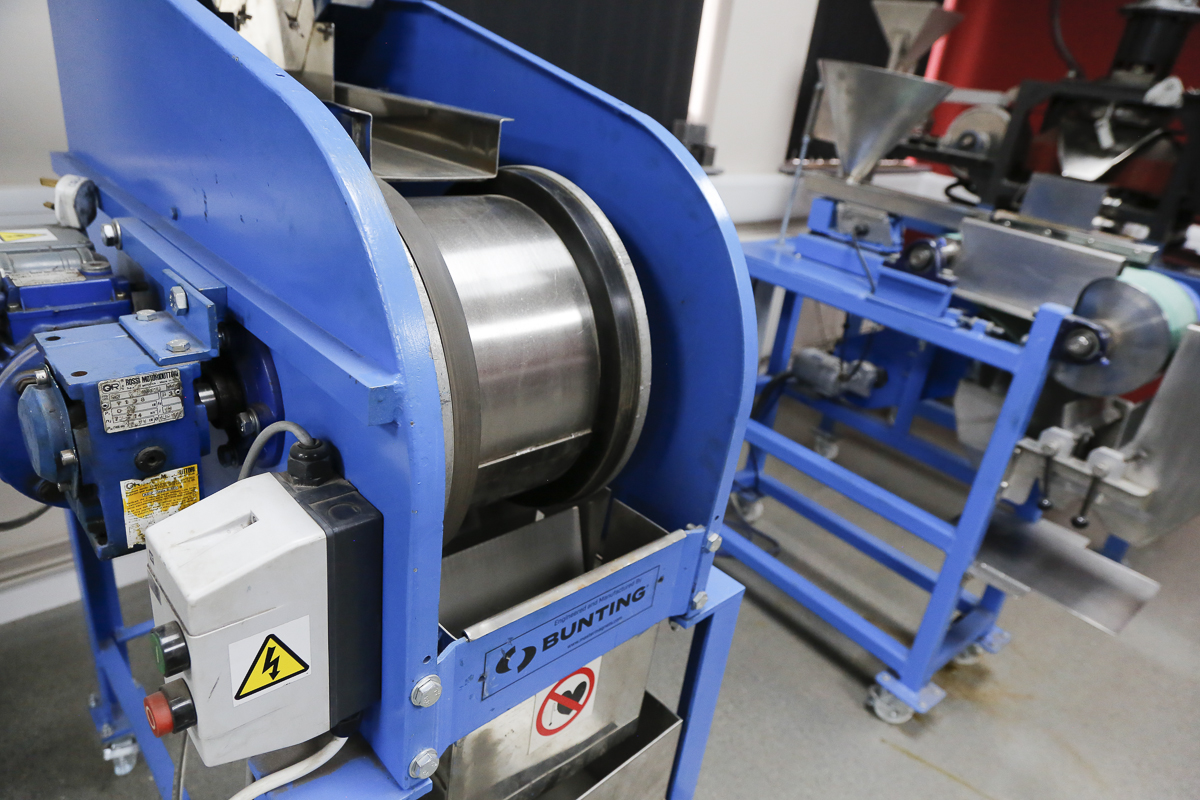

The Bunting Customer Experience Centre at Redditch, UK is home to one of the world’s most complete collections of laboratory-scale magnetic separators. The technology has been developed over several decades and is purchased by globally-located research institutions, universities, mining companies and recyclers. The technology focuses on the ability to separate magnetically susceptible materials for recovery or removal. Bunting designs and builds laboratory-scale magnetic separators for research projects globally.

Related blogs

- Lab Equipment for University of Birmingham

- New XRF Enhances Mineral Testing Capabilities

- Recycling Test Facility

- Chute Magnet Separator Checks Magnetic Susceptibility

Applications

Research institutions and universities use the facilities at Redditch and also purchase laboratory-scale magnetic separators when investigating new mineral reserves and recycling techniques.

The range of laboratory magnetic separators are suitable for testing on:

- Dry minerals;

- Wet mineral slurries;

- Spray dried ceramics;

- Ceramic slips and glazes;

- Secondary waste materials for recycling (e.g. incineration ash, waste plastic, secondary metals, etc)

Models

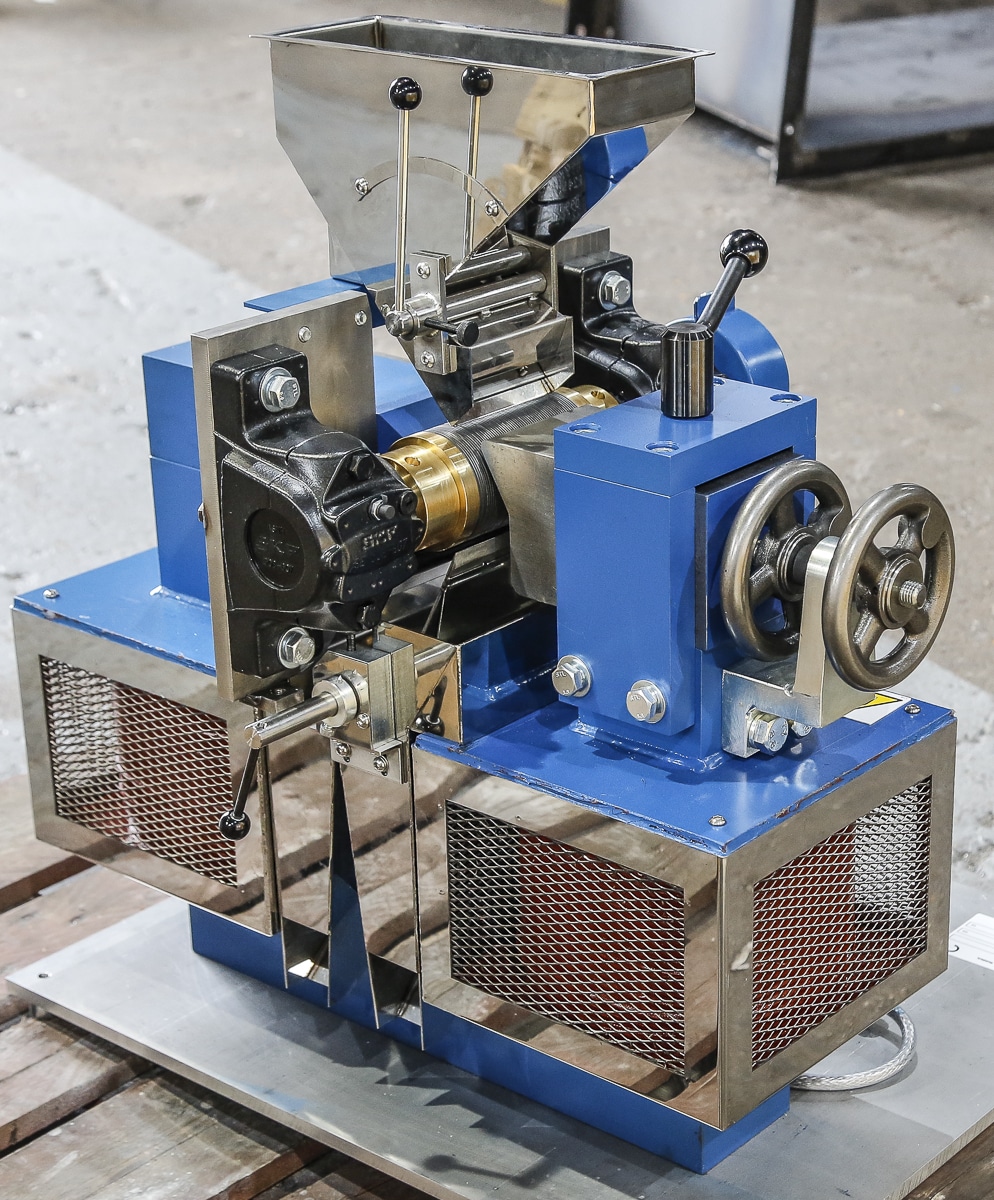

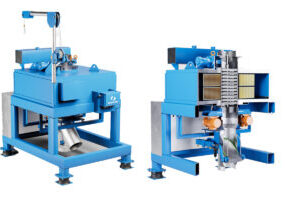

Dry Mineral Processing

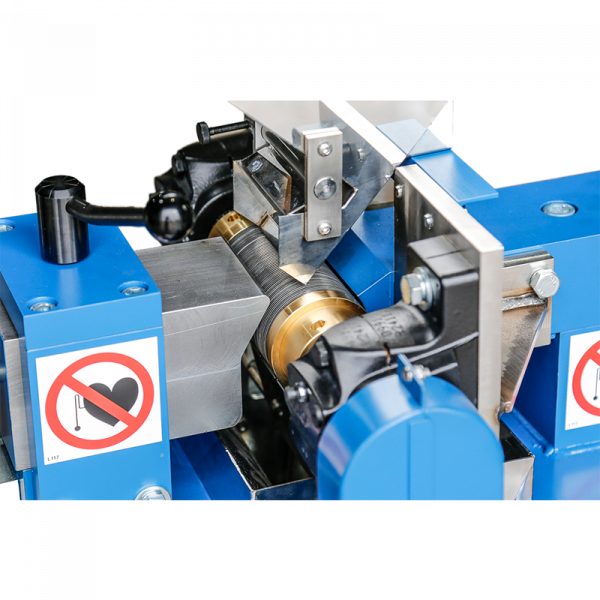

- Induced Roll Magnetic Separators;

- Magnetic Disc Separators (MDS);

- Rare Earth Roll Separators;

- Electrostatic Separators

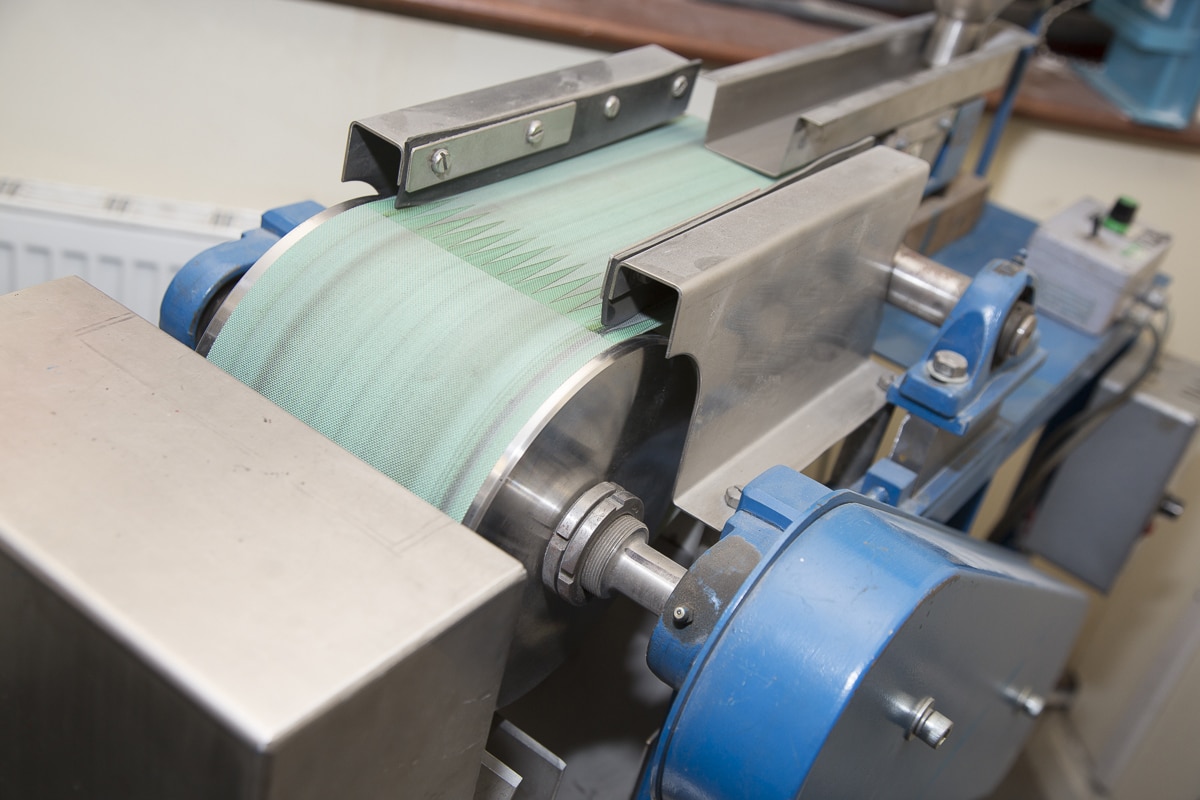

Wet Mineral Processing

- Magnetic Slide;

- Wet High Intensity Magnetic Separator;

- ElectroMagnetic Filter;

- Chute Magnet Separator;

Recycling

Videos

Disc Separators for Mineral Processing

Induced Roll Magnetic Separator

Rare Earth Roll Separators

Stainless Steel Separator

Eddy Current Separator

Chute Magnet Separator

Wet High Intensity Magnetic Separator (WHIMS)