FEATURES

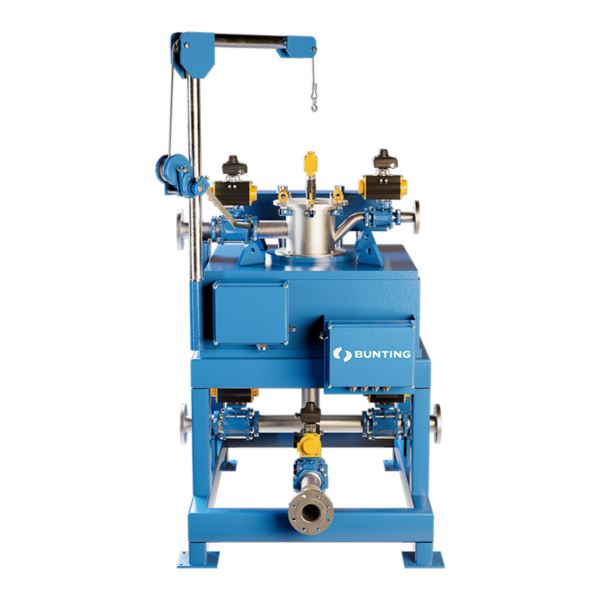

Easy Maintenance

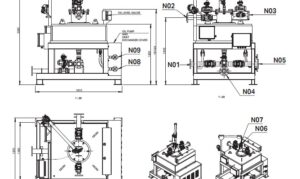

Includes a removable jib crane to remove the top pole and matrix assembly.

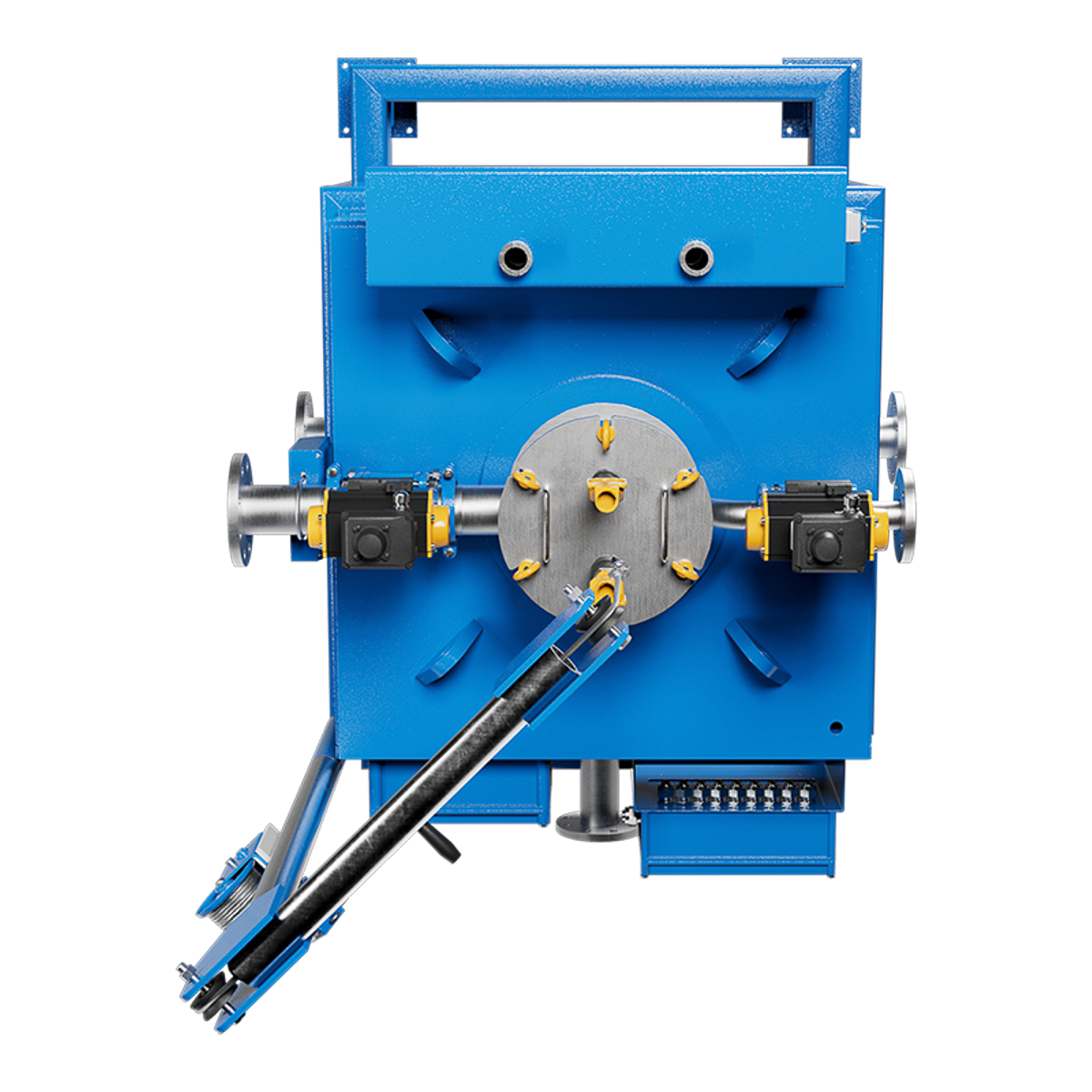

Back Flush Cleaning

Automated back flush cleaning cycle to clean contaminants from the matrix.

ANIMATIONS

Cleaning

Full Screen Option Available

Electromagnetic Removal

Full Screen Option Available

ABOUT

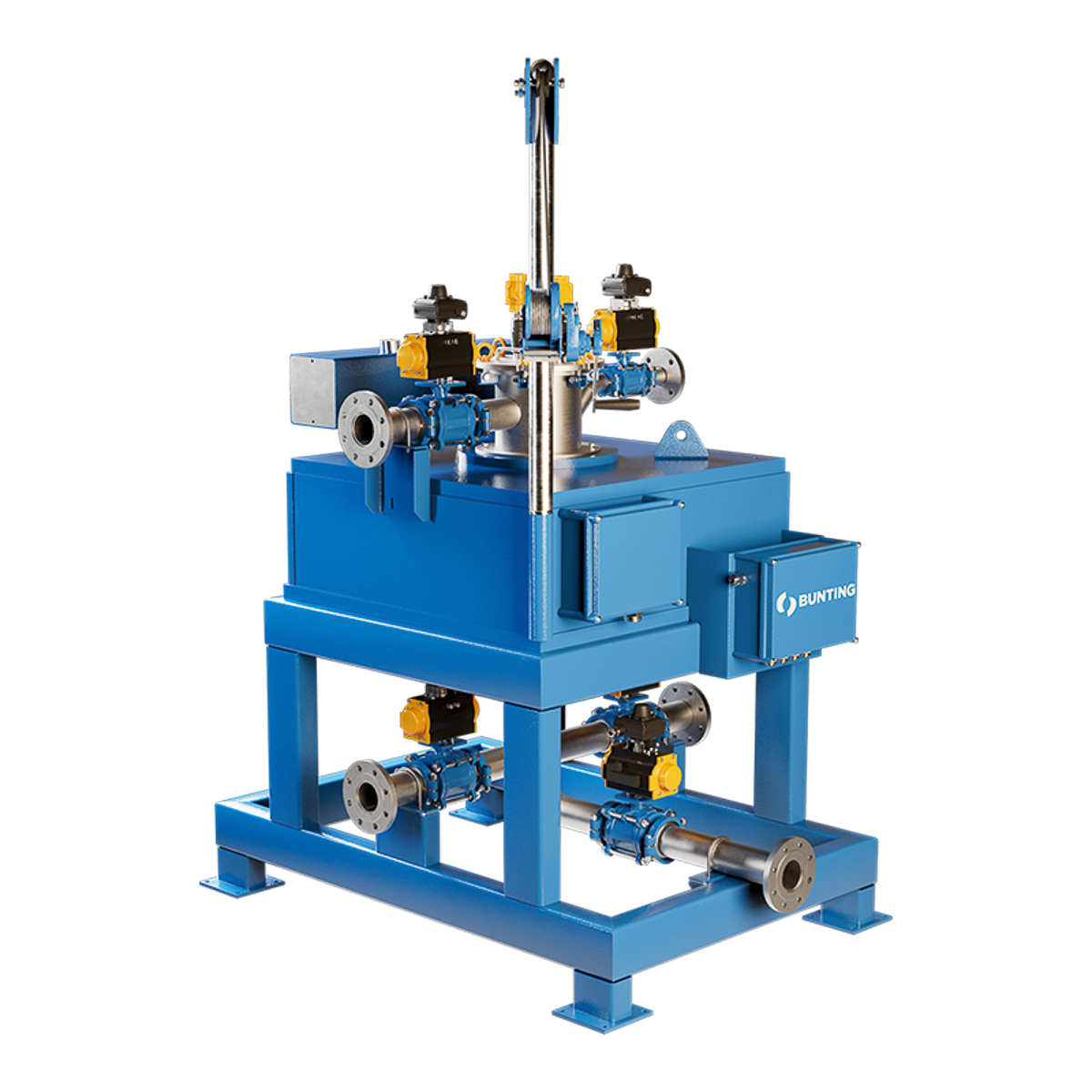

Electromagnetic Filters: Powerful Magnetic Separation Technology

Electromagnetic filters provide highly effective removal of fine iron and paramagnetic minerals from ceramic slips, glazes, and industrial mineral slurries. Key features include:

- Generate strong magnetic fields up to 10,000 Gauss for superior separation efficiency

- Remove problematic magnetic particles as small as 0-500 microns

- Automated cleaning cycles for continuous processing

- Available in 3,500 to 10,000 Gauss models for different applications

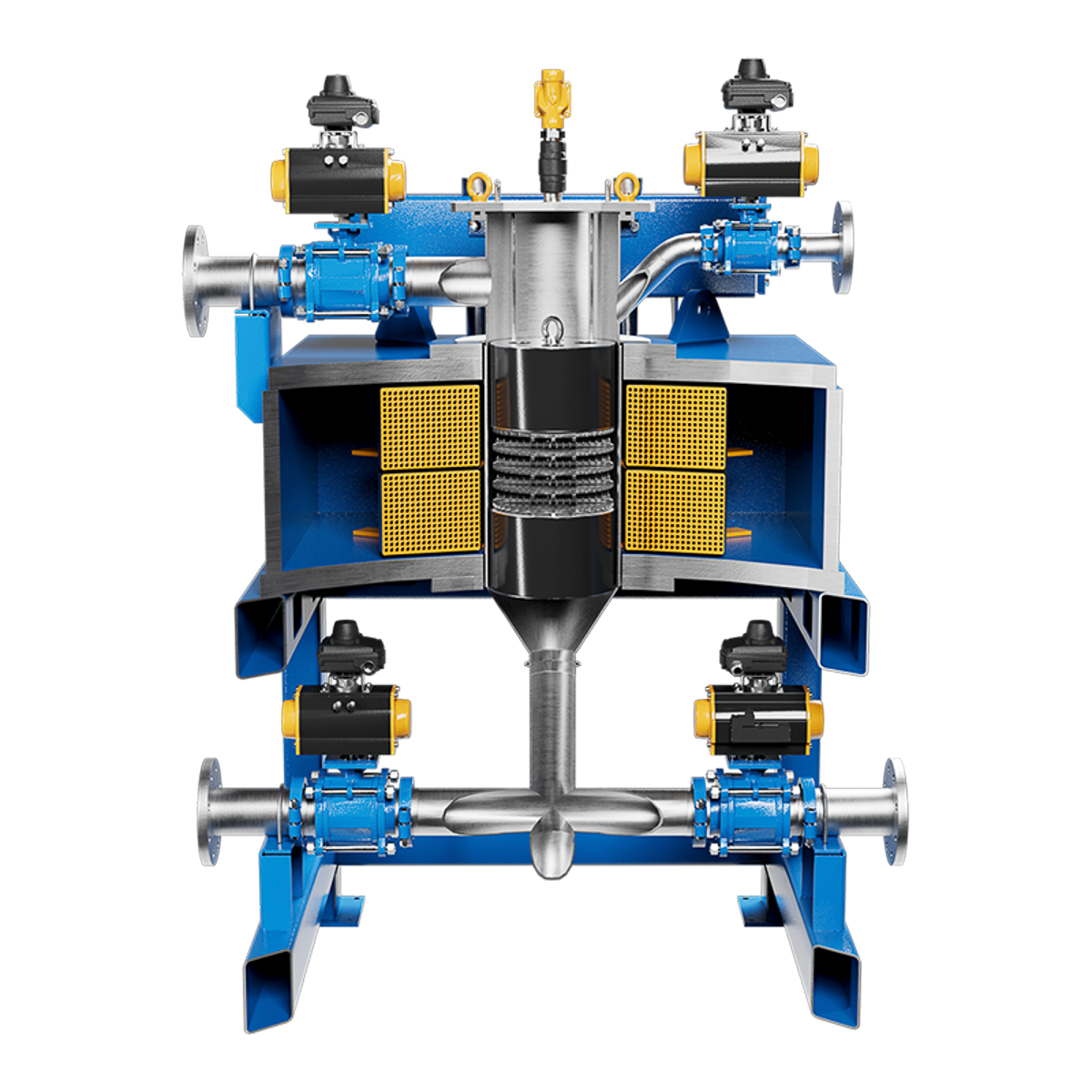

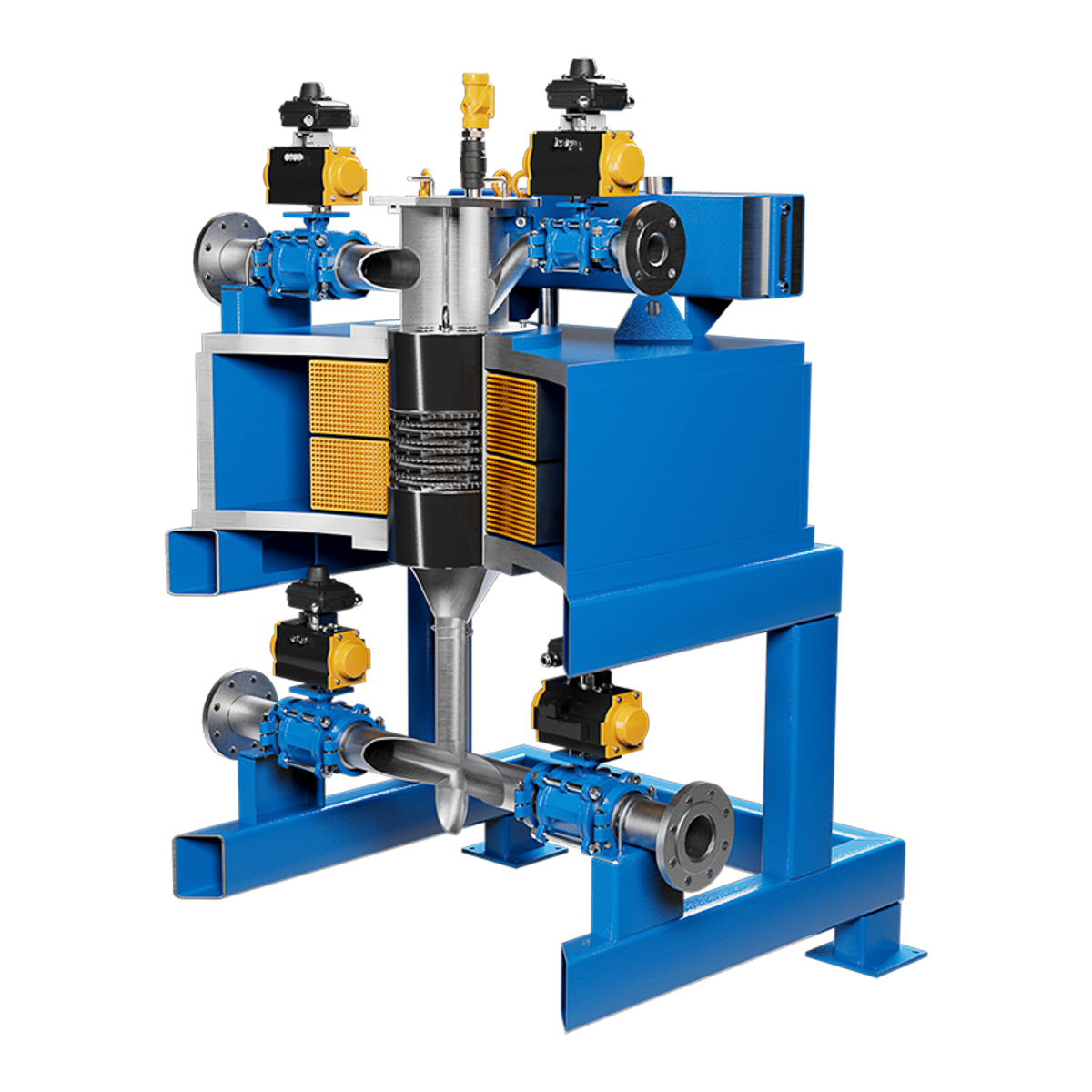

How Electromagnetic Filters Work

- Electromagnetic coil creates intense magnetic field in stainless steel matrix

- Slurry pumped through matrix, magnetic particles attracted and captured

- Periodic cleaning cycles flush out captured particles

- Can be set up in pairs for non-stop operation

Key Benefits

- More effective than permanent magnetic separators

- Removes very fine iron and paramagnetic minerals

- Improves purity of ceramic materials and industrial minerals

- Automated operation with programmable controls

Common Applications

- Cleaning ceramic glazes and slips

- Purifying mineral slurries like silica sand, feldspar, kaolin, etc.

- Removing contaminants from ball clay, calcium carbonate, talc

For industries requiring high-purity materials, electromagnetic filters offer powerful magnetic separation capabilities to remove even the finest magnetic contaminants. Their adjustable field strength and automated operation make them ideal for a wide range of ceramic and mineral processing applications.