Description

Bullet Magnets are one of the most common magnetic separators found in installations handling free-flowing dry bulk materials such as grain, flour and seeds.

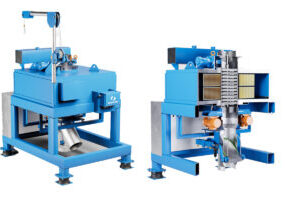

Flanges on the top and bottom of the Bullet Magnet enable easy installation into existing vertical pipelines and free-fall chutes which transport material. Bullet Magnets consist of a stainless steel housing with a maintenance door on which the magnet system is attached to, the magnet system is positioned in the centre of the housing and therefore in the middle of the free-falling product stream. A splitting cone distributes the material homogeneously over the cylindric magnet system. The magnet element is either made out of Neodymium Iron Boron or Strontium Ferrite depending on the application. Guide stripes within the housing ensure that the material is directed as close as possible to the surface of the magnet.

Related Blogs

Operation

In operation, dry granular materials or powders are fed, under gravity, into the top of the Bullet Magnet. The material strikes the centrally-mounted cone, around which it then flows close to the surface of the magnet. Any ferrous metal contamination is attracted to one of the magnet’s poles and held securely. During scheduled maintenance, on a frequency determined by the level of ferrous metal contamination, the Bullet Magnet is opened and the captured ferrous metal is manually cleaned from the surface of the magnet.

Models

Bullet Magnets are designed to easily connect into pipelines with diameters between 100 and 500mm.

Available with either Ceramic Ferrite or Rare Earth Magnets depending on the application:

- Ceramic Ferrite: Ideal for the removal of larger tramp ferrous metal such as nuts, blots, screws, rust, etc. because of their deep magnetic field.

- Rare Earth: A higher intensity magnet suitable for capturing fine iron as well as larger tramp ferrous metal due to the exceptionally strong magnetic fields.

Applications

Bullet Magnets are extremely versatile and are used in a wide range of applications including:

- Food processing plants,

- Grain

- Cereals

- Seeds

- Flour

- Plastic manufacturing operations

- Recycling

- Ceramics

- Raw materials

- General powder and bulk handling