Belt Conveyor Metal Detectors

Industrial Metal Detectors for Belt Conveyors

Belt Conveyor Metal Detectors are designed to detect and then reject any kind of metal from a belt conveyor system. The maintenance of these machines is simple and they are incredibly user-friendly when it comes to operation.

TN77 Metal Detector for Mining & Quarrying

- Detection of tramp iron & low-grade manganese steel, including non-magnetic digger teeth.

- Reliable protection against machinery damage

- Simple to operate with fully adjustable sensitivity and detection levels

- Capable of overlooking non-magnetic, copper-alloy belt fasteners

Tunnel metal detector for installation in belt conveyors, vibratory chutes, material slides and drop chute.

- Detects all metals encapsulated or as loose parts.

- High sensitivity in rough industrial environments.

- User friendly and reliable technology, proven for many years.

- A worthwhile investment that protects the valuable production equipment.

- Specifically tailored system solutions with reliable conveying technology and selected accessories.

Divisible tunnel metal detector for installation in belt conveyors, vibratory chutes and material slides.

- Detects all metals in solid products or as loose parts.

- High sensitivity in rough industrial environments.

- User friendly and reliable Technology, proven for many years.

- A worthwhile investment that protects the valuable production equipment.

- Quick and easy to install.

- Specifically tailored system solutions with reliable conveying technology and selected accessories.

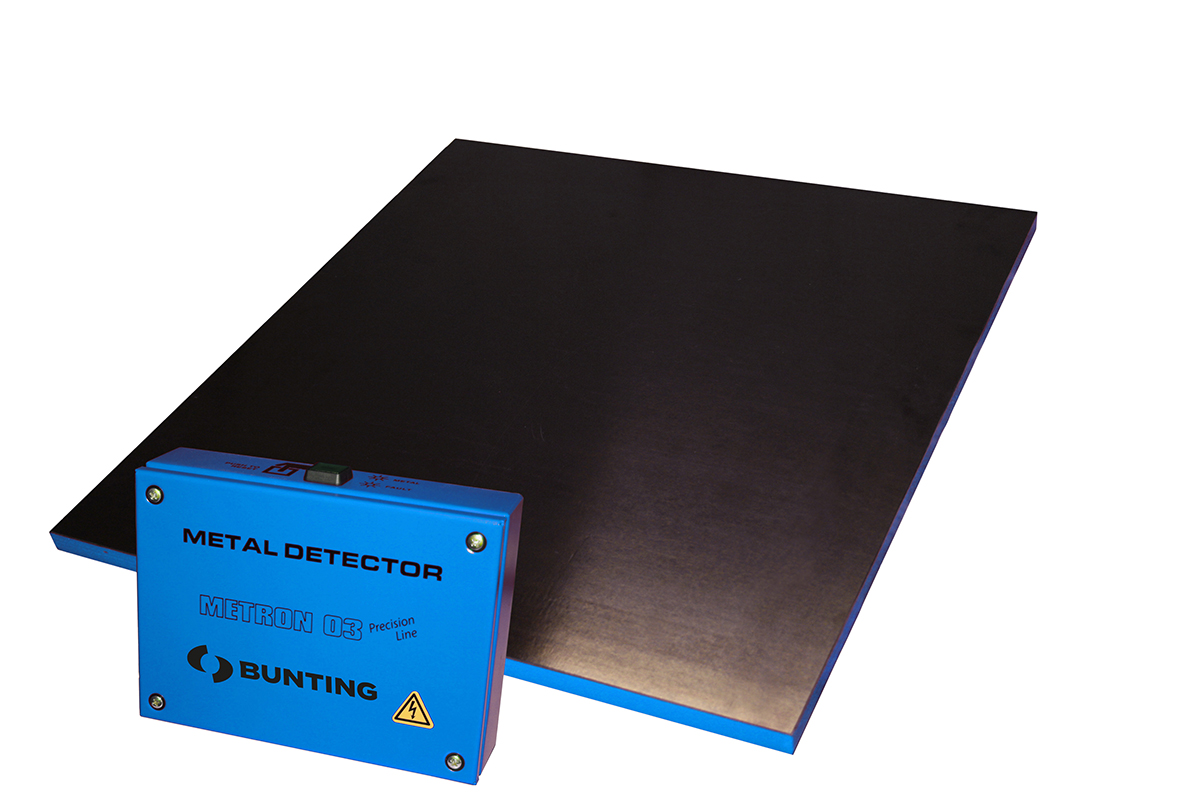

Compact plate metal detector for the installation in small load belt conveyors.

- Detects all metals as inclusions or as loose parts.

- For smaller bulk heights or for the inspection of hollow bodies.

- Does not require a ‘metal-free zone’.

- High sensitivity in rough industrial environments.

- Excellent machine protection despite small investment costs.

- User friendly and reliable technology, proven for many years.

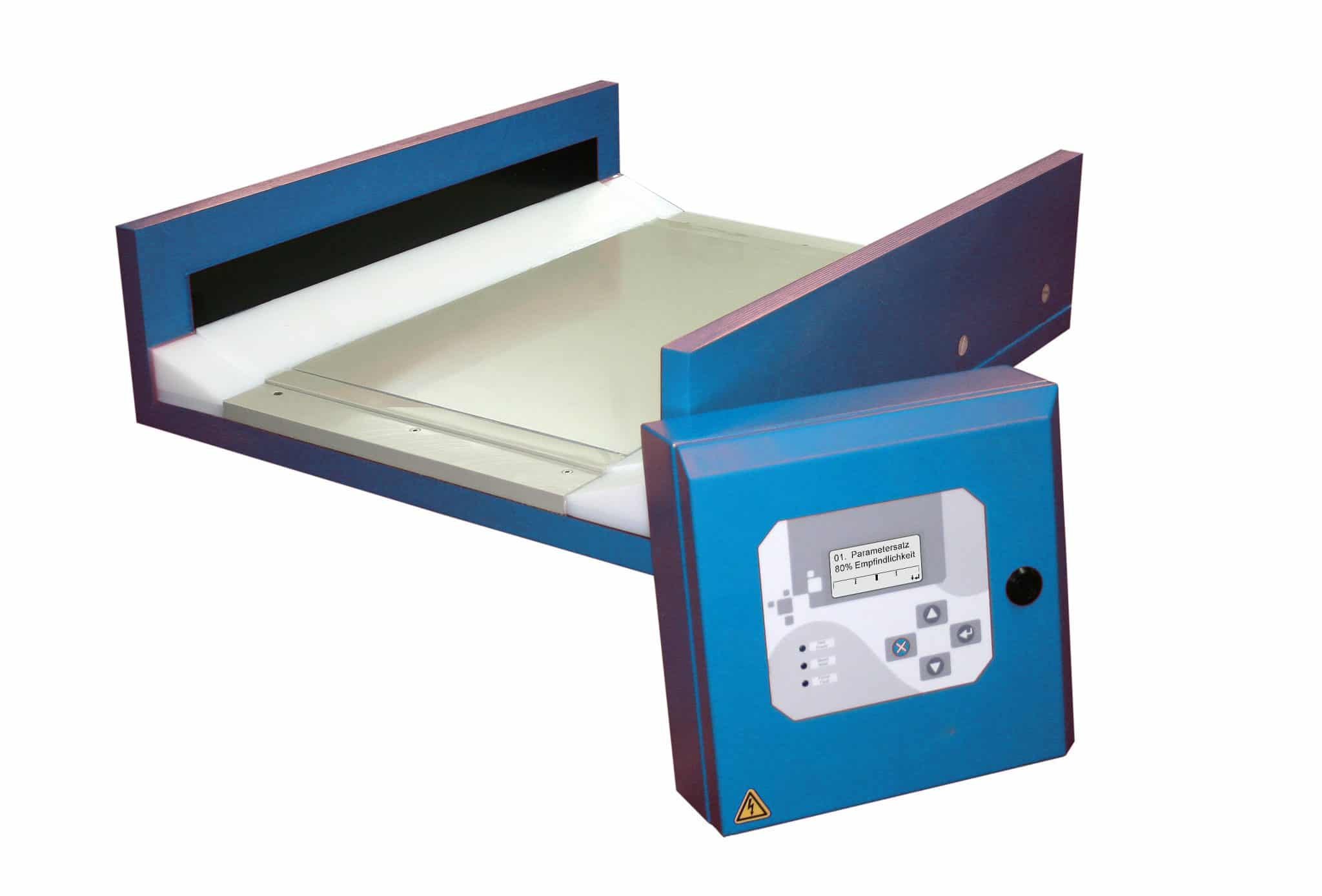

Single surface metal detector for installation in belt conveyors, vibratory chutes and material slides.

- Detects all metals encapsulated or as loose parts.

- For medium bulk heights.

- High sensitivity in rough industrial environments.

- Reliable machine protection with little investment.

- User friendly and reliable technology, proven for many years.

- Quick and easy to install.

- Specifically tailored system solutions with reliable conveying technology and selected accessories.

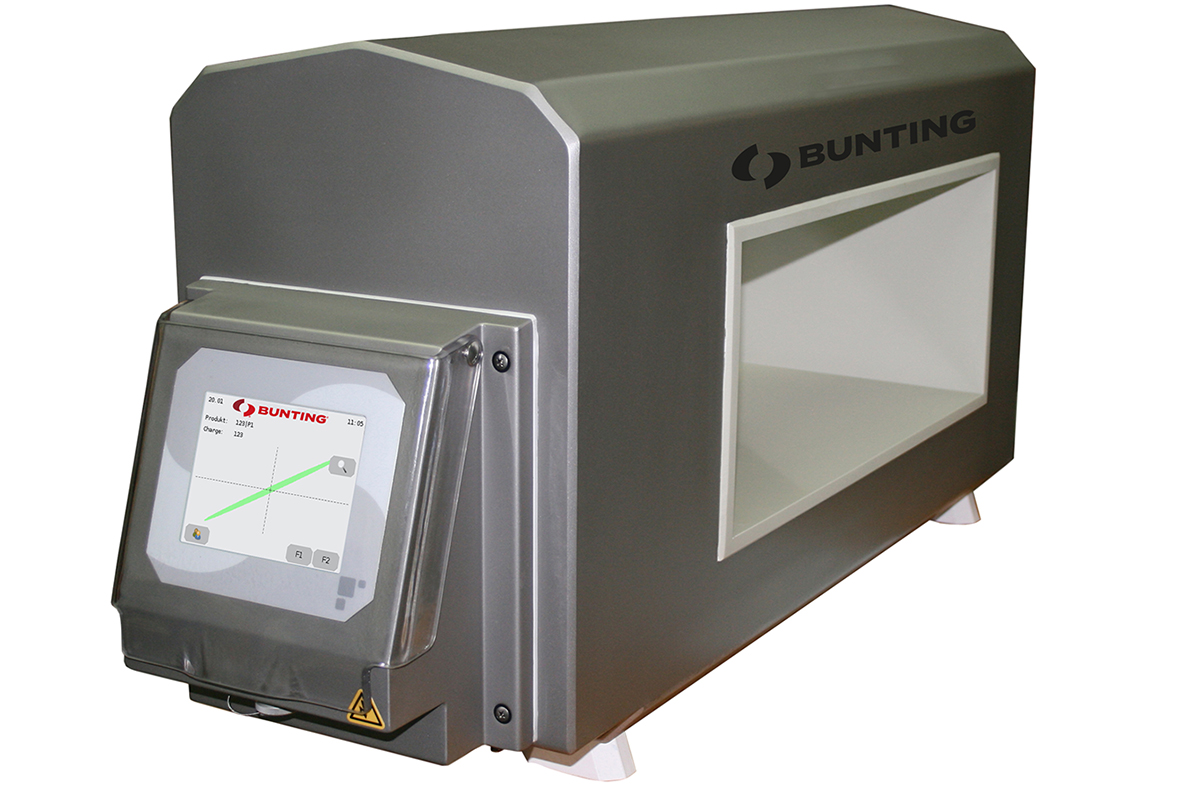

Tunnel metal detector with integrated evaluation electronic -used in belt conveyors for quality control or machine protection.

- Detects all metals encapsulated or as loose parts.

- The new performance benchmark, imagePHASE visualizes your product and is a synonym for highly accurate metal detection at maximum reliability.

- Impressive simple operation.

- Compliant with quality assurance according to HACCP, IFS, BRC, SQF.

- Specifically tailored system solutions with reliable conveying technology and selected accessories.

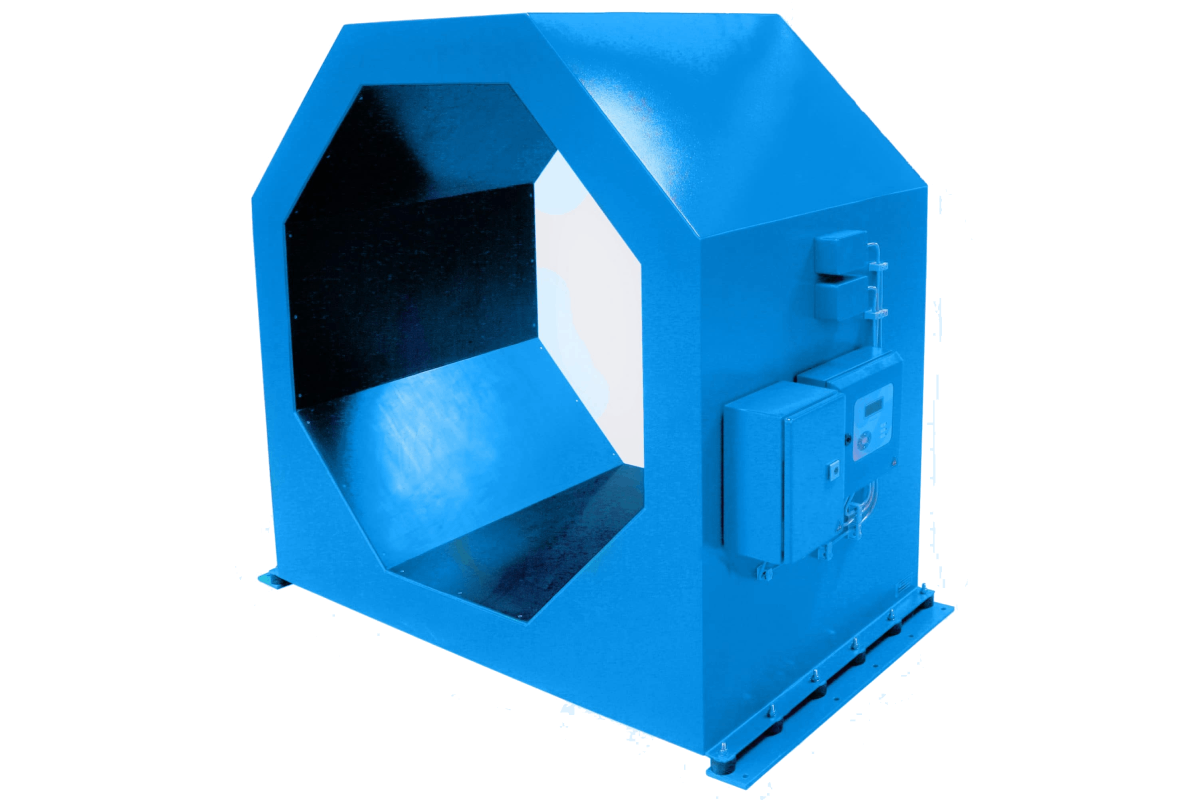

A tunnel-based metal detector with integrated evaluation electronics, to be installed in conveyor belts.

- Designed to detect and reject tramp metal in non-metallic and non-conductive material

- Digital signal processing for optimum metal detection

- Designed to last, a high-quality build ensures product durability

- A variety of aperture sizes are available to suit specific customer requirements

- Easy installation, can be integrated into conveyor belts or product chutes

- Multiple versions are available to better meet application-specific requirements (temperature resistance, outdoors etc.)

meTRON 05 VT

For the direct installation into the trough of a vibratory conveyor.

- Detects all metals encapsulated or as loose parts.

- Reliable machine protection through high detection accuracy.

- Quick and easy to install.

- Minimal investment.

- Customized solutions for all trough types and sizes.

- User friendly and reliable technology, proven for many years.

meTRON 05 CO

Metal detector for the examination of timber in your log processing plant.

- Detects all metals encapsulated or as loose parts.

- High sensitivity even in rough sawmill environments.

- Minimal space requirement (reduced metal free zone).

- A worthwhile investment that protects your machinery.

- Increase your profit by minimizing downtime

transTRON

Special conveying systems.

Conveying of packed and bulk products in the production process with “metal free area” for the integration of metal detector.

- Budget sparing individualised solutions.

- Guaranteed long-term, trouble-free metal detection results.

- Continuous operation, reliable and with low maintenance.

- Systems available for nearly any application, from mill feeding over bag checking to the Transport of textile fibres.