Inline Magnet Pros and Cons

By Paul Fears | 21 September 2020

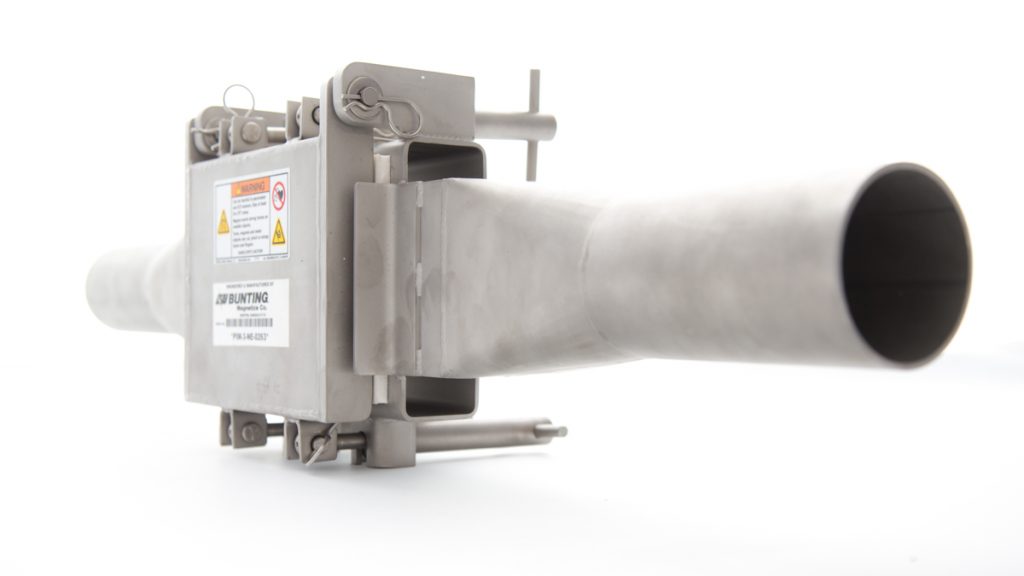

The Inline Magnet is a versatile and popular magnetic separator used widely to capture tramp ferrous metal contamination. The non-obstructive design suits applications in many different applications including food processing and plastics. In this blog, we review the different designs and the Inline Magnet’s key advantages and disadvantages

Inline Magnet Models

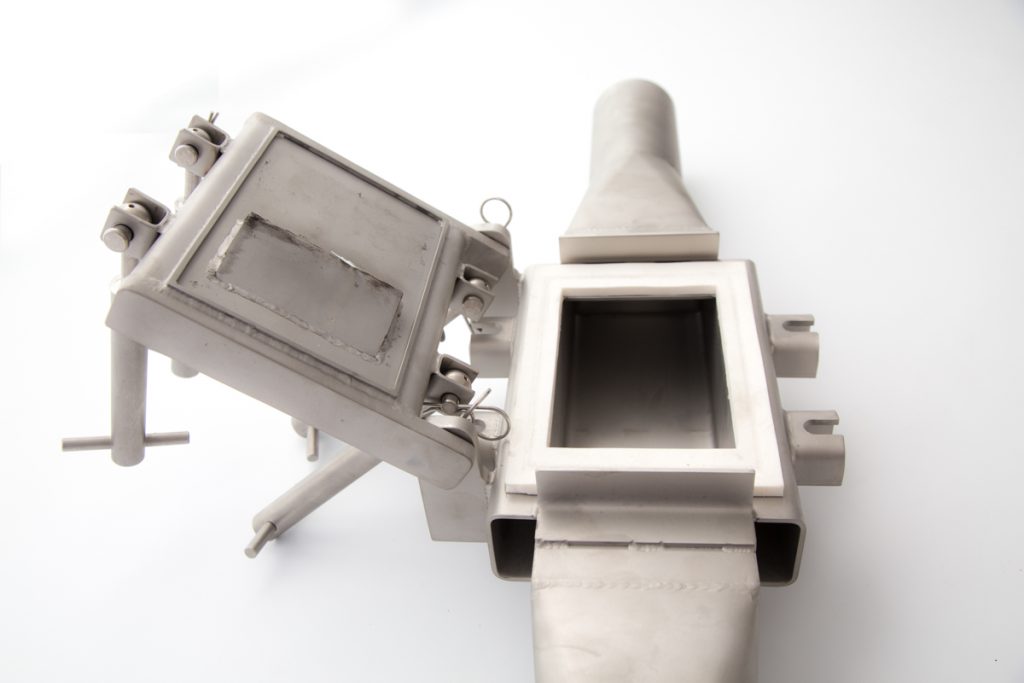

The Inline Magnet is designed to easily connect into pipelines with diameters between 50 and 250mm. A Plate Magnet, mounted on one side of a tube, attracts and holds ferrous metal contamination. During scheduled maintenance, the hinged Plate Magnet is unfastened, lifted out of the product stream and cleaned.

- Technical product information: Inline Magnet

The Plate Magnet is either constructed from Ceramic Ferrite or Neodymium Rare Earth. Ceramic Ferrite Magnets produce a deep magnetic field in contrast to the exceptionally strong but shallower field generated by Neodymium Rare Earth. The nature of the ferrous metal contamination determines the type of magnet.

There are two designs of the Inline Magnet featuring a Plate Magnet:

- Gravity Inline Magnets (GIM);

- Pneumatic Inline Magnets (PIM);

The Bullet Magnet, which features a cone magnet mounted in the centre of the product flow rather than a Plate Magnet, is not included in this review.

Pros and Cons of the Inline Magnets

The versatility of the Inline Magnet means that it is used across a wide range of industries including food processing, plastics, ceramics, recycling, mineral processing, chemicals, and bulk handling. However, the Inline Magnet is not ideal for every metal separation application. When assessing the potential use of the Inline Magnet for a specific application, our engineers will consider specific pros and cons

Pros of the Inline Magnet

- Limited restriction to the product flow: The mounting of the Plate Magnet on one side of the Inline Magnet means that the product flow is unimpeded, thus reducing the chance of any blockages;

- Deep magnetic field: When using a Ceramic Ferrite Magnet, the deep magnetic field reaches right across the product flow and is powerful enough to drag ferrous metal into the capture zone. Once on the magnet face, the ferrous metal is held firmly until manually removed;

- Securing held ferrous metal contamination: On both the Ceramic Ferrite and Neodymium Rare Earth models, the strong magnetic field ensures that any captured ferrous metal is held firmly on the face and does not get knocked off by product flow;

- Easy cleaning: During plant maintenance, the hinged Plate Magnet is unconnected from the pipe and captured ferrous metal manually removed from the surface;

- Installation: With a range of pipe diameters and pipe adapters to suit any process, the Inline Magnet is easily installed into new and existing process lines;

Cons of the Inline Magnet

- Internal pipe diameter: As with any Plate Magnet, there is a limit to the depth of magnetic field. Subsequently, the maximum internal pipe diameter is nominally 250mm for the Ceramic Ferrite Magnet and narrower for the Neodymium Rare Earth Magnet. Commonly, the Dual Deep Field Magnet or Diagonal Leg Plate Magnet, featuring two Plate Magnets, provide optimum ferrous metal separation from larger diameter chutes and pipes;

- Manual cleaning: Periodically, captured ferrous metal is cleaned off the face of the Plate Magnet. This is undertaken manually, usually on an agreed cleaning schedule. Magnetic separators providing automatic and continuous ferrous metal separation and removal include the Drum Magnet, although the design may not easily fit into an existing process;

- Non-ferrous metal: A magnetic separator only captures magnetically-susceptible metals such as ferrous, magnetic stainless-steel and some work-hardened stainless-steel. Metal Detectors, such as the quickTRON series, find and can remove non-ferrous metal contamination;

The selection of a magnetic separator or metal detector for any application depends on the installation and separation objective. Bunting’s applications engineers use years of experience to recommend the optimum solution for any metal-contamination problem. For further information on the Bunting Inline Magnet or to discuss a specific metal contamination problem, please contact our technical sales team on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

All photographs taken by Paul Fears Photography

Follow us on social media