Wood Processing

Removing Metal Contamination from Wood Processing

- Overband Magnets – these magnetic separators sit over conveyors and lift larger ferrous metal contamination out of the conveyed shredded wood. Multi-pole designs reduce the risk of belt piercing from sharp pointed objects such as nails;

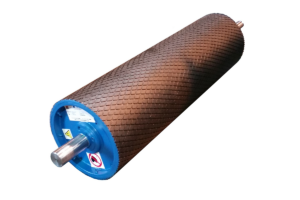

- Drum Magnets and Pulley Magnets – The Electro Drum Magnet or the Pulley Magnet provides enhanced ferrous metal separation, especially of smaller tramp ferrous metal. Due to the abrasive nature of metals such as nails, Drum Magnets are commonly supplied with manganese steel wear wraps;

- Eddy Current Separators – physically and continuously ejects non-ferrous metals (eg. aluminium door handles and hinges) out of the flow of the shredded wood;

- Metal Detectors – mounted under and over conveyors to provide a final check prior to entering a shredder, and to check the final finished board usually prior to cutting. Specialist metal detector designs check complete logs for metal contamination prior to shredding;

Technical Articles

Wood Processing Industry Products

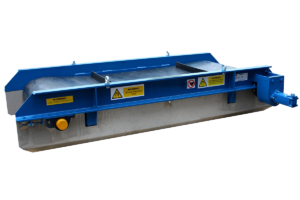

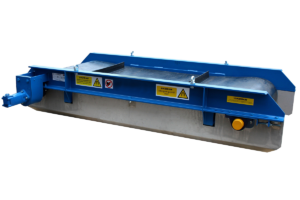

Overband Magnets

Overband magnets, suspended over conveyors, remove problematic ferrous metals (e.g. nails, screws, etc) and are available as permanent and electromagnetic designs.

Suspension Magnets

Suspension Magnets, suspended over conveyors, separate occasional ferrous metal and protect equipment such as shredders. Available in permanent and electromagnetic versions.

Drum Magnets - Electro

Heavy-duty large diameter Electro Drum Magnets remove ferrous metal from high-volume shredded wood lines such as for power generation.

Magnetic Head Pulleys

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of ferrous metals from conveyed products.

Magnetic Sweepers

Magnetic sweepers clear ferrous debris off floors, yards, car parks and other areas to prevent damage to equipment and vehicles.

Eddy Current Separators for Non-Ferrous metals

Separate large and small non-ferrous metals, such as hinges, door handles and brass screws, from shredded wood.

Overband Magnets

Suspension Magnets

Drum Magnets - Electro

Magnetic Head Pulleys

Magnetic Sweepers

Eddy Current Separators for Non-Ferrous metals

Conveyor Metal Detectors

Log Metal Detectors

Conveyor Metal Detectors

High-sensitivity metal detectors mounted around a conveyor to locate any metal contaminant present in the transported shredded wood.

Log Metal Detectors

Specialist metal detector for the timber industry, detecting all metals present in logs with high-sensitivity even in sawmill environments.

Metal Separators for the Wood and Timber Industry

Whether sourced as virgin wood from log stock or from recycled wood (e.g. pallets), shredded wood will contain both ferrous and non-ferrous metals. This is in a variety of forms from nails, aluminium hinges, and even bullets.

After a primary stage of shredding, most of such metal contamination is liberated to such a degree that it can be separated. Some metal will be free, whilst other metal may still be embedded in the wood. Before the shredded wood enters the next stage of shredding, such metal contamination is removed.

Eddy Current Separators for the Wood and Timber Industry

When recycling wood, there is an additional risk of non-ferrous metal contamination such as aluminium door hinges and handles, and brass fittings and screws. Eddy Current Separators eject the non-ferrous metal from the shredded wood. The Eddy Current Separators used to remove non-ferrous metals are capable of handling high-volumes of shredded wood.

Metal Detectors for Wood Processing

Metal Detectors feature in locations where there is a high risk of equipment damage or fire. Positioned either around a conveyor or on a log-feeding station, the high-sensitivity metal detectors identify any metal contamination and either stop the process for removal or automatically reject the contaminated material.