Getting Metal Out of Chocolate

By Paul Fears | 07 July 2020

Chocolate is one of the most desired and loved food substances in the world. Whether the preference is milk, dark or white, chocolate brings happiness to millions of people. And for producers, providing a perfect bar of chocolate is essential. That’s why chocolate producers use a wide range of magnetic separators and metal detectors in their production process, capturing, detecting and removing any metal contamination.

Chocolate is made from the exceptionally hard cocoa beans. The process of breaking down those beans results in equipment wear and even failure, with the potential of metal contamination. However, a series of carefully selected and positioned magnetic separators and metal detectors remove any metal.

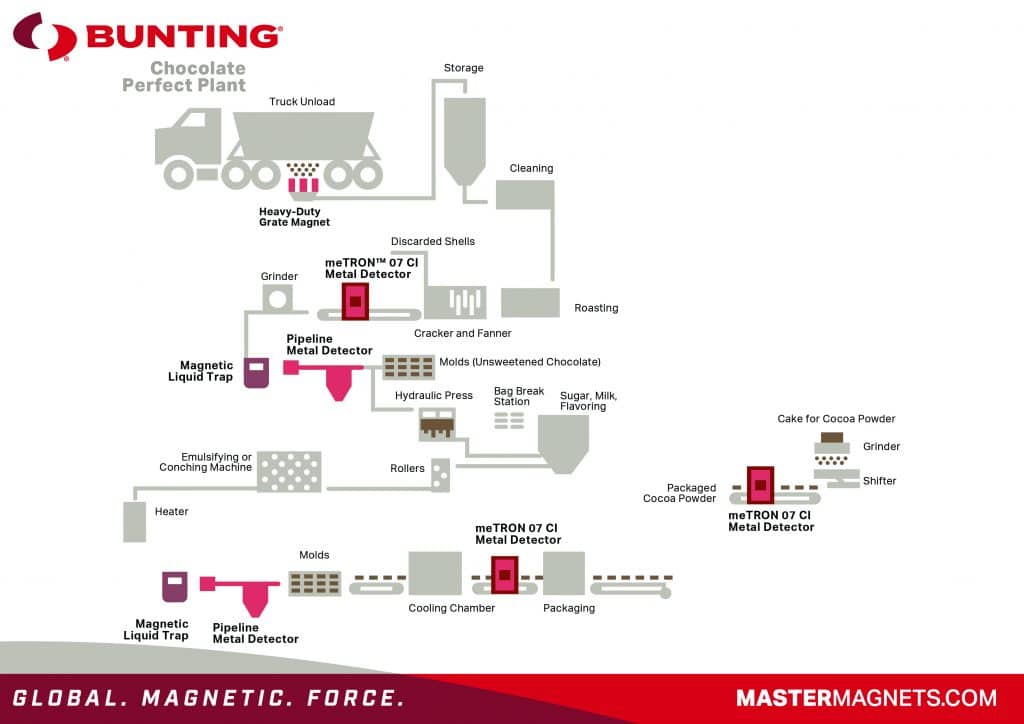

In this review, and using the flowsheet (Figure 1), we assess a typical chocolate manufacturing process and identify optimum locations for both magnetic separators and metal detectors.

Stages of Ensuring Metal-Free Chocolate

Stage 1 – Raw Material Delivery

Despite strict controls, metal contamination is often introduced into a food manufacturing process with the raw materials. In this example, the delivered cocoa beans are discharged through a heavy duty Grate Magnet, which captures any larger tramp ferrous metal, such as nails, nuts and bolts. Removing the larger metal at this stage stops such contamination getting smaller (and more difficult to remove), whilst also preventing damage to processing equipment.

- Technical product information: Grate & Grid Magnets

Stage 2 – Post Bean Roasting and Cracking

After the cocoa beans have been cleaned and roasted, they are cracked with the shells being discarded and the nuts being fed into the process. The cracking process may either cause equipment wear or release entrapped metal contamination. Subsequently, the nuts are fed under or over the surface of a Plate Magnet. This attracts and holds any ferrous metal contamination.

- Technical product information: Plate Magnet

This stage is also a good location to detect any potential non-ferrous metal contamination using a Metal Detector (meTRON 07 CI) before passing onto the grinder. The combination of the Plate Magnet and Metal Detector protect the grinder from being damaged by metal liberated in the cracking process.

- Technical product information: Metal Detector (meTRON 07 CI)

Stage 3 – Post Grinding

After the grinder, the nuts have been converted into a chocolate liquor. The process of grinding will introduce fine metal into the process (from wear of the grinder). Prior to either being moulded into unsweetened chocolate or passing on for further processing, the liquor is passed through metal separators designed for installation into liquid or slurry pipelines; a Magnetic Liquid Trap removes fine iron followed by a Metal Detector for the detection of non-ferrous metals.

- Technical product information: Magnetic Liquid Trap

Stage 4 – Cocoa Powder

The chocolate liquor passes through a hydraulic press where it is split into cocoa butter and cake for cocoa powder. The cocoa cake is fed onto a grinder and screen with the packaged cocoa powder being passed through a Metal Detector meTRON 07 CI on a conveyor as a final check.

Stage 5 – Addition of Sugar

There is always risk of introducing metal contamination with any raw materials being added into the process. The sugar and milk flavour additives are fed through a HF Drawer Magnet to capture and hold any fine tramp ferrous metal before being mixed with the cocoa butter. This ensures that the new chocolate mix is metal-free before passing to the rollers, which are highly susceptible to damage from such metal contamination.

- Technical product information: HF Drawer Magnet

Stage 6 – Hot Molten Chocolate Mix

After mixing and passing through a series of rollers, the mixture is emulsified before being heated. This molten hot mix is then passed through a special Magnetic Liquid Trap with a waterjacket. Hot water circulating in the waterjacket stops any molten chocolate from cooling whilst in the body of the Filter.

Due to the high temperature of the molten chocolate, care is needed when selecting the specification of the magnets used in the Tube Magnets of the Magnetic Liquid Trap. High temperatures irreversibly damage the magnetic field of many standard neodymium magnets.

After passing through the Magnetic Liquid Trap, featuring special high-temperature resistant neodymium magnets, the mixture is passed through a Pipeline Metal Detector to detect any non-ferrous metal. This joint protection is a final stage before the chocolate is formed into shape in moulds.

Stage 7 – Final Check

After the chocolate is fed into moulds it is then cooled. The final check is after cooling, when the moulded and formed chocolate is then fed on a conveyor through a Metal Detector (Metron C) prior to packaging. Once packed, the metal-free chocolate is despatched for sale to the millions of chocolate lovers all over the world.

Multi-stage Metal Detection and Magnetic Separation may appear excessive, but is the best way to ensure that the end product is metal-free whilst also preventing damage to delicate processing equipment. As illustrated, the focus is on areas where metal may be introduced (material input) or released (process equipment wear or potential failure) as part of the production process.

Related Metal-in-Food Technical Articles

For further information on ‘Getting Metal Out’ of Chocolate or any foodstuffs, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media