Chocolate Safety with Liquid Magnetic Separators

By Paul Fears | 10 February 2025

A UK chocolate conche manufacturer has purchased five (5) Bunting Liquid Magnetic Separators to capture ferrous metal contamination generated during the chocolate manufacturing process.

Conching is a key part of chocolate making involving the continuous mixing, grinding, and kneading of chocolate mass over a prolonged period. The conche is a machine specifically designed for the process and is essential to refine chocolate, ensuring a smooth and consistent texture.

Chocolate is made from the exceptionally hard cocoa beans. The process of breaking down those beans results in equipment wear and even failure, with the potential of metal contamination. This could be the broken wire of a screen, metal from a broken pump, or abraded stainless-steel and very fine iron from process plant wear. However, a series of carefully selected and positioned magnetic separators, such as the Liquid Magnetic Separator, and metal detectors remove any metal.

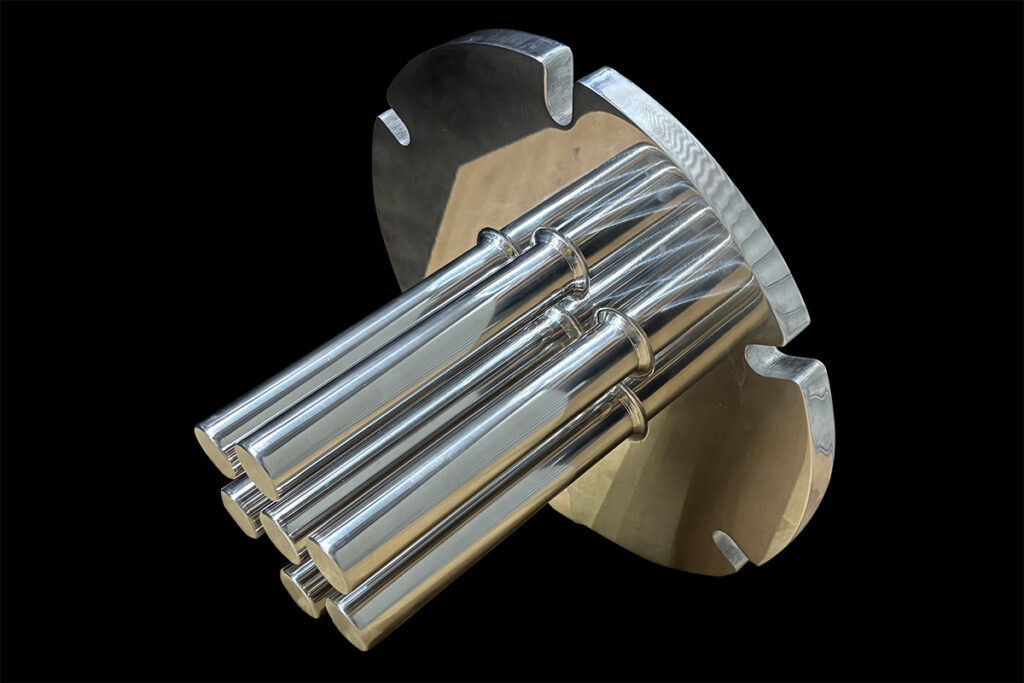

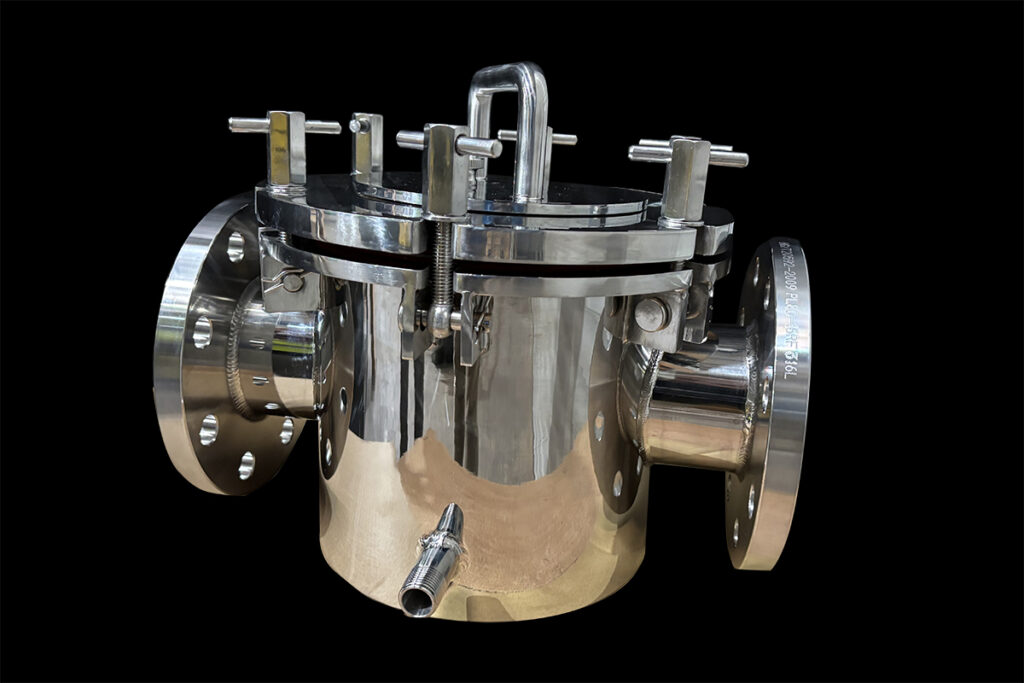

The Bunting Liquid Magnetic Separator, that is designed specifically for chocolate manufacturing, features an outer water jacket through which runs hot water to ensure the liquid mass does not solidify and remains molten. Inside the water-jacketed stainless-steel body sits a vertically aligned set of seven (7) high-strength neodymium tube magnets. The tube magnets sit tightly inside an outer stainless-steel sleeve for easy cleaning. The flanged ends of the Liquid Magnetic Separator ensure easy installation into any pipeline.

In operation, molten chocolate flows into the body and through and around the offset lattice of tube magnets. The high magnetic strength of the tube magnets attracts and securely retains any metal contamination on the surface of the outer sleeve. During scheduled regular maintenance, dictated by the level of metal contamination, the process is stopped and the tube magnet assembly is removed. The sleeves are then disconnected from the tube magnets allowing for captured magnetics to be flushed off the surface of the outer tube. The magnetics are often very fine in nature. The cleaning process using the easy clean design is very short, keeping production disturbance to a minimum.

The Liquid Magnetic Separators MLT-3-EC supplied to the conche manufacturer are for installation onto a 3-inch (75mm) pipeline.

“The challenging process of turning hard cocoa beans into chocolate results in potential equipment wear and, therefore, metal contamination,” explained Peter Buckley, Bunting’s General Separation Technical Sales Engineer. “The simple but exceptionally powerful Liquid Magnetic Separator captures any metal, protecting process plant further down the line and ensuring the quality of the end chocolate product.”