News

Mineral Processing & Magnetic Separators, Bauma 2019

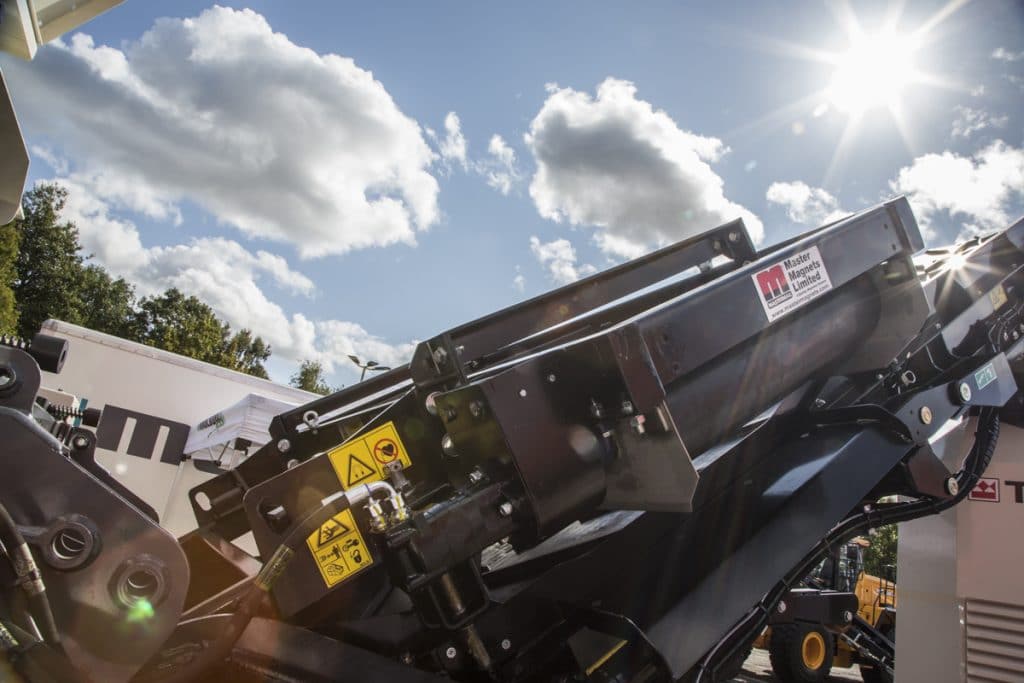

The latest generation of high intensity Magnetic Separators will be on display on the Bunting Magnetics and Master Magnets stand (Hall B2 Stand 133) at Bauma 2019. The metal and mineral separators are used widely in the mineral processing, quarrying and recycling industries. Also, a new design of Magnetic Separator is being launched at the…

Read MoreLarge Pulley Magnets for Mining Project

Two 1.2 metre diameter Pulley Magnets have been manufactured and supplied to a mining operation in Sweden. The Pulley Magnets are used to extract large tramp metal from iron ore prior to crushing and screening. Removing the tramp metal protects the other processing equipment and prevents damage to conveyors. The mining operation originally purchased three…

Read MoreNew Recycling Test Facility

Following an increase in the demand for material testing, Bunting has constructed a new recycling test facility at their manufacturing operation in Redditch. Initially, the facility will house two models of Stainless-Steel Magnetic Separator and an Eddy Current Separator. New Recycling Test Facility “We are seeing an increase in the number of controlled material tests,”…

Read MoreSkip Hire Magazine Visits Master Magnets

A visit from Scott Golland and Richard Hollis from Skip Hire Magazine provided us with an ideal opportunity to update them on exciting developments at our Redditch plant. Following announcing a 25% growth in sales in 2018 on 2017, we have started the year strongly with three (3) orders for Stainless Steel Magnetic Separators. Skip Hire…

Read More3 Stainless Steel Magnetic Separators Sold In January 2019

Orders for 3 SSSC model Stainless Steel Separators The success of 2018 flowed into January 2019 with three orders for SSSC model Stainless Steel Magnetic Separators. All three orders are for different customers with specific metal separation objectives. “This is a fantastic way to start 2019,” said Dave Hills, Head of Sales. “Interest in the…

Read MoreMineral Processing Lab High Intensity Electromagnetic Filter

A high intensity Electromagnetic Filter has expanded the mineral testing capabilities in the Bunting-Redditch mineral processing laboratory. The Electromagnetic Filter is designed to remove fine iron and weakly magnetic materials from mineral slurries and ceramics slips and glazes. The new equipment expands the extensive range of high intensity magnetic separators already used in the test…

Read MoreMaster Magnets Sponsor Physical Separation 2019

Magnetic Separation – International Mineral Conference Master Magnets has been announced as one of the principle sponsors of the Physical Separation ’19 conference (13-14 June, National Maritime Museum, Falmouth, Cornwall, UK). Physical Separation ’19 is organised by Minerals Engineering International (MEI). Although chemical methods of concentration and extraction dominate the industry, the physical separation methods are ubiquitous. …

Read MoreMagnetic Separator and Metal Detector Growth in 2018

UK Manufacturing Success for Master Magnets Sales and enquiries for magnetic separators and metal detectors hit new highs in 2018. A 25% sales growth for the European Bunting Magnetics operation came two years after the Master Magnets acquisition in January 2017. “It has been an incredible year,” said our General Manager, Adrian Coleman. “Demand has…

Read MoreInternational Electronics Recycling Congress 2019

Talking Magnetic Separators at IERC 2019 The Bunting Magnetics and Master Magnets team are exhibiting (stand 17) at this month’s 18th International Electronics Recycling Congress IERC 2019 (January 16-18, Salzburg, Austria). IERC 2019 is an important biennial event on the recycling industry calendar, bringing together international producers, recyclers, equipment manufacturers, recycling associations, refurbishers, standards bodies, NGOs,…

Read More2018 Review

A Look Back at our News & Blogs in 2018 2018 proved to be another exciting year. Despite the spectre of BREXIT, business overseas continued to flourish and grow. We attended a number of international exhibitions, securing orders on the stand. There have also been concerns on the UK mainland about waste management and especially…

Read More