News

Chocolate Safety with Liquid Magnetic Separators

A UK chocolate conche manufacturer has purchased five (5) Bunting Liquid Magnetic Separators to capture ferrous metal contamination generated during the chocolate manufacturing process. Conching is a key part of chocolate making involving the continuous mixing, grinding, and kneading of chocolate mass over a prolonged period. The conche is a machine specifically designed for the…

Read MoreMetal Contaminated UK Food Recalls 2024

There were fourteen (14) food alerts issued by the UK’s Food Standards Agency relating to metal contaminated food in 2024. These alerts are only raised when the presence of metal poses a potential risk to the consumer. The metal contaminated food products were produced by a wide range of suppliers, many of whom provide foods…

Read MoreSolving Quarrying and Mining Tramp Metal Problems

Tramp metal exists in all mining and quarrying operations. The problematic contamination is difficult to avoid. The nature of mining and quarrying – extracting ore and aggregate using large heavy equipment – results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage…

Read MoreModified ToughFlex® Belt for Overband Magnets

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions. Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over…

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read MoreBunting Welcomes Ben Clemett as UK South Territory Sales Manager

Bunting is excited to announce the appointment of Ben Clemett as the Territory Sales Manager for the Southern area of the United Kingdom. Ben brings extensive experience and a strong passion for innovation to this important role, where he will focus on expanding Bunting’s presence in the quarrying, mining, and recycling sectors. Ben’s impressive background…

Read MoreNecessity of Cleaning Magnetic Separators

When on site, our Technical Sales Engineers often take opportunity to check the installed magnetic separators. At many sites, this results in a conversation about the required cleaning frequency for a permanent magnetic separator such as a Drawer Filter Magnet, Plate Magnet, or Liquid Magnetic Separator. This is when captured ferrous metal is manually removed…

Read MoreElectro Suspension Magnet Preference for Compost Supplier

A leading UK compost supplier has replaced two permanent suspension magnets with Bunting’s electro suspension magnets. The additional power of electro suspension magnets enables enhanced separation of small ferrous metals such as nails. The supplier of compost assessed methods to improve the level of ferrous metal separation for two separate process lines. Previously installed were…

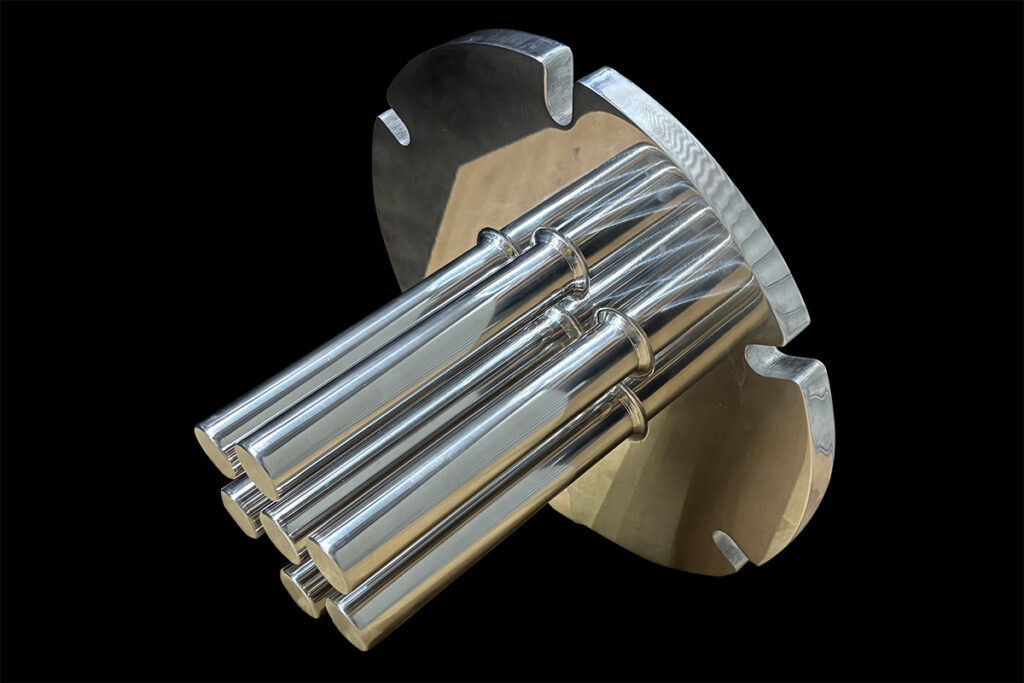

Read MoreNew FF Drawer Filter Magnet

Following a customer-driven redesign, Bunting’s new FF Series Drawer Filter Magnet is easily fitted into an extended range of granulators, injection moulding machines and other plastics manufacturing and processing plant, eliminating the need for customisation. Drawer Filter Magnets use powerful Neodymium tube magnets, arranged in a grid, to capture and extract ferrous particles from dry,…

Read MoreAtherton Material Handling Installs Bunting Suspension Electro Magnet

Atherton Material Handling has installed a Bunting Suspension Electro Magnet at a calcium carbonate quarry in Melton, UK. The Suspension Electro Magnet removes tramp ferrous metal prior to a metal detector, reducing the number of metal detection trips and increasing productivity. Atherton Material Handling originally contacted Bunting to find a solution to the problem of…

Read More