News

ElectroStatic Separators Destined for Australia

Bunting Magnetics has designed and built two ElectroStatic Separators for a metal recovery company based in Australia. The metal separation technology will recover precious metals from shredded printed circuit boards. The electrostatic separator provides the only known method of removing or recovering metals from certain recycled materials. Separation occurs by inducing an electrostatic charge into…

Read MoreWestern Bio-Energy Clean Woodchip with an EMAX Overband Magnet

Bunting Magnetics has supplied a powerful EMAX Overband Magnet to Western Bio-Energy to remove problematic ferrous metal from woodchip. The air-cooled electromagnetic Overband Magnet is removing a wide range of small and larger sized tramp metal. Western Bio-Energy Ltd operates a sustainably resourced 15.8MWh Biomass Power Plant exporting electricity to the grid and is based…

Read MoreMetal Removed from Plastic Regrind

The combination of a magnetic separator and metal detector is removing rogue metal contamination from recycled plastic regrind before the material is mixed into other raw materials used for the manufacture of plastic products including handles and hinges. At the plant, waste generated from plastics injection moulders and in the manufacturing process is reground for…

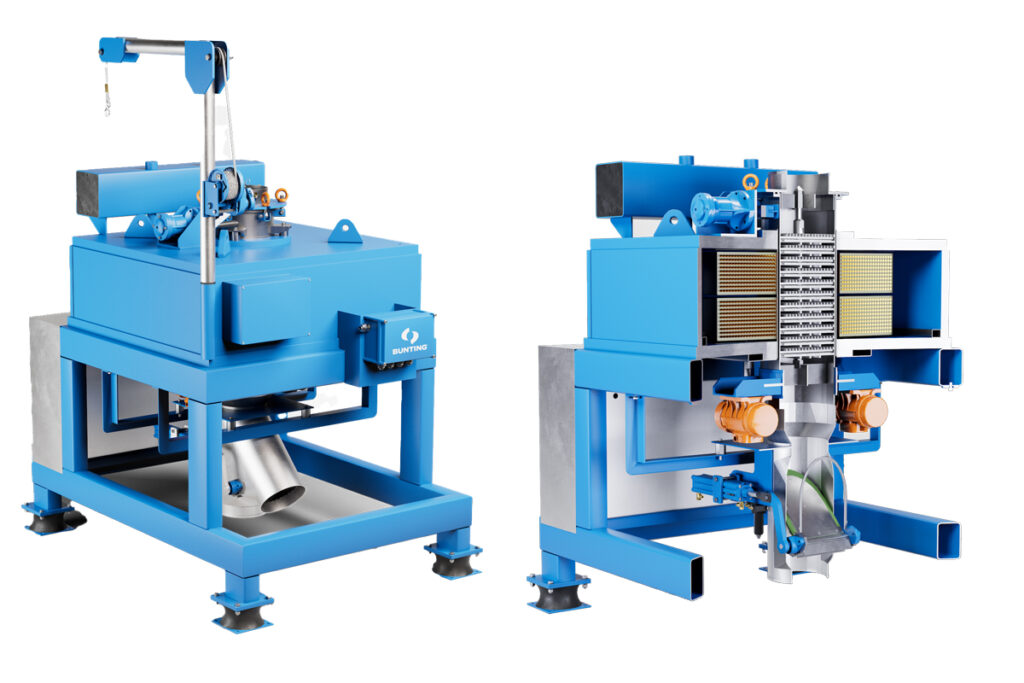

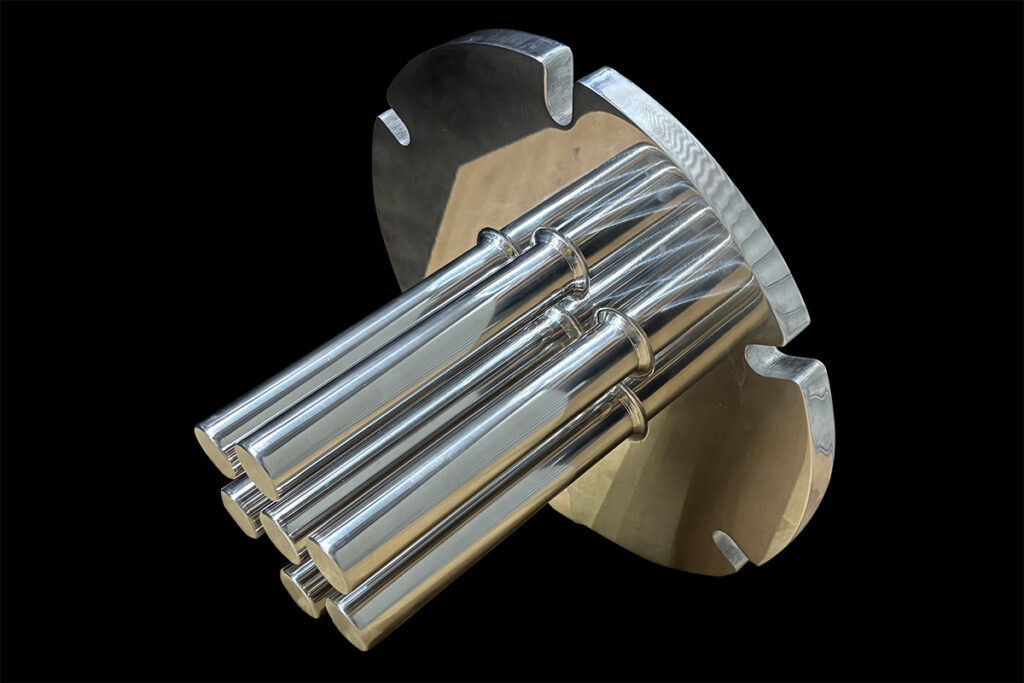

Read MoreBunting Develops High-Intensity Electromagnetic Dry Filter

Bunting has developed a new Electromagnetic Dry Filter to remove free fine iron from powders. The high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.…

Read MoreMagnetic Separation in Mining and Mineral Processing

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals. Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. …

Read MoreChocolate Safety with Liquid Magnetic Separators

A UK chocolate conche manufacturer has purchased five (5) Bunting Liquid Magnetic Separators to capture ferrous metal contamination generated during the chocolate manufacturing process. Conching is a key part of chocolate making involving the continuous mixing, grinding, and kneading of chocolate mass over a prolonged period. The conche is a machine specifically designed for the…

Read MoreMetal Contaminated UK Food Recalls 2024

There were fourteen (14) food alerts issued by the UK’s Food Standards Agency relating to metal contaminated food in 2024. These alerts are only raised when the presence of metal poses a potential risk to the consumer. The metal contaminated food products were produced by a wide range of suppliers, many of whom provide foods…

Read MoreSolving Quarrying and Mining Tramp Metal Problems

Tramp metal exists in all mining and quarrying operations. The problematic contamination is difficult to avoid. The nature of mining and quarrying – extracting ore and aggregate using large heavy equipment – results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage…

Read MoreModified ToughFlex® Belt for Overband Magnets

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions. Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over…

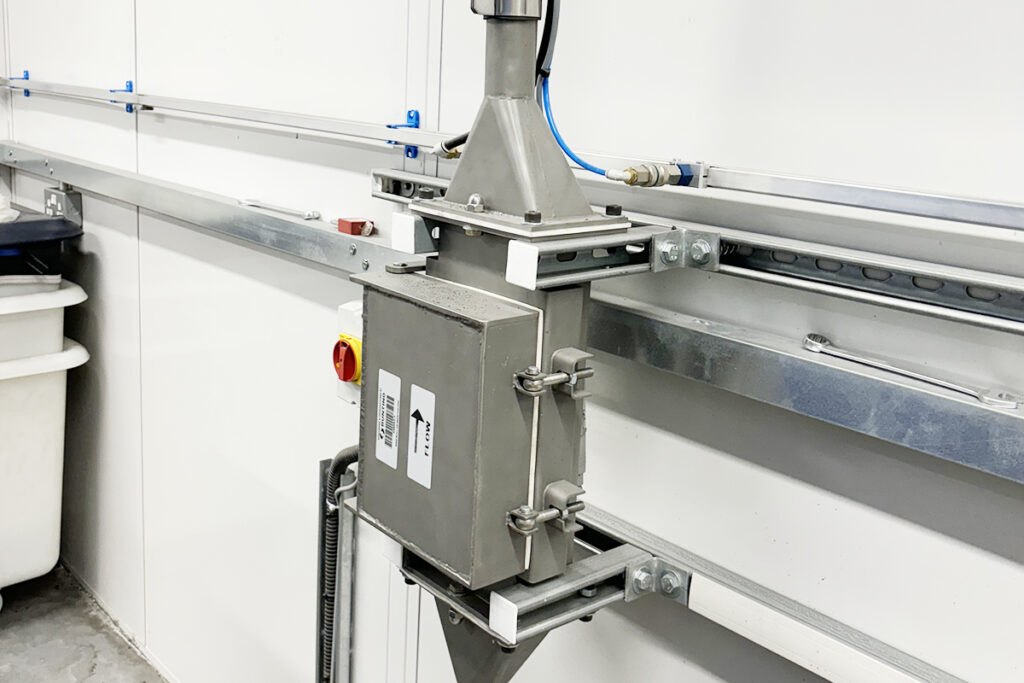

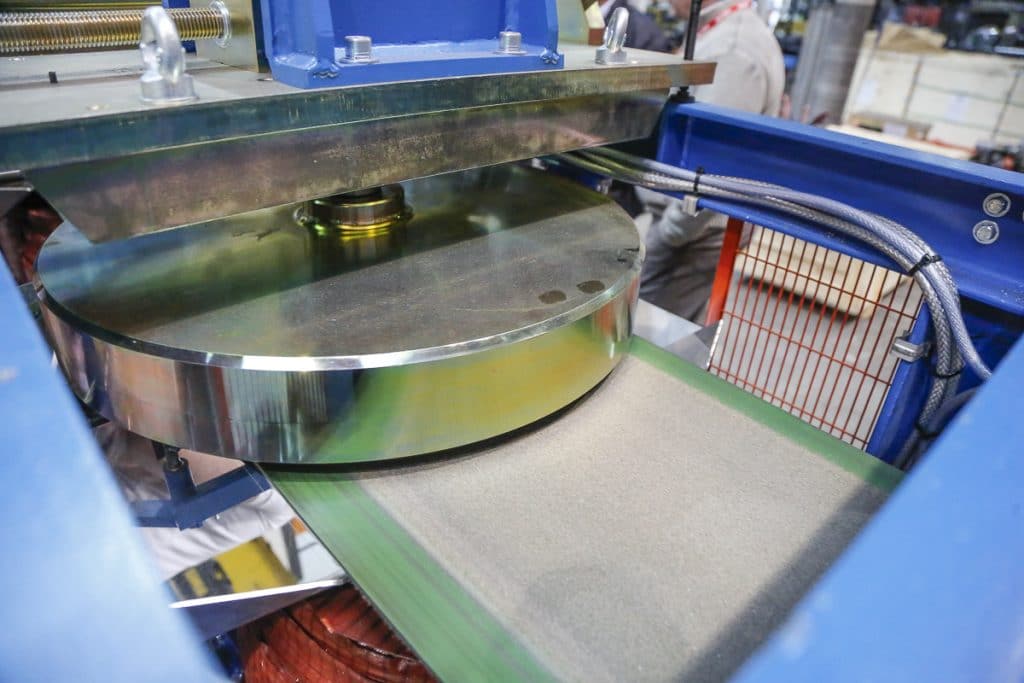

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read More