Recycling

ElectroStatic Separators Destined for Australia

Bunting Magnetics has designed and built two ElectroStatic Separators for a metal recovery company based in Australia. The metal separation technology will recover precious metals from shredded printed circuit boards. The electrostatic separator provides the only known method of removing or recovering metals from certain recycled materials. Separation occurs by inducing an electrostatic charge into…

Read MoreWestern Bio-Energy Clean Woodchip with an EMAX Overband Magnet

Bunting Magnetics has supplied a powerful EMAX Overband Magnet to Western Bio-Energy to remove problematic ferrous metal from woodchip. The air-cooled electromagnetic Overband Magnet is removing a wide range of small and larger sized tramp metal. Western Bio-Energy Ltd operates a sustainably resourced 15.8MWh Biomass Power Plant exporting electricity to the grid and is based…

Read MoreMetal Removed from Plastic Regrind

The combination of a magnetic separator and metal detector is removing rogue metal contamination from recycled plastic regrind before the material is mixed into other raw materials used for the manufacture of plastic products including handles and hinges. At the plant, waste generated from plastics injection moulders and in the manufacturing process is reground for…

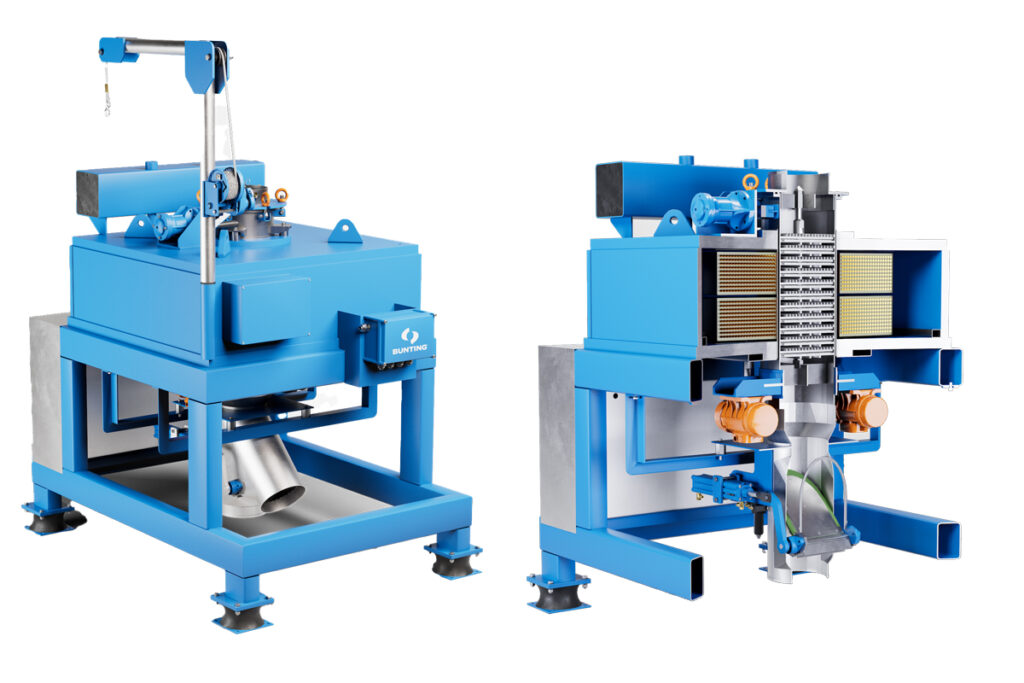

Read MoreBunting Develops High-Intensity Electromagnetic Dry Filter

Bunting has developed a new Electromagnetic Dry Filter to remove free fine iron from powders. The high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.…

Read MoreModified ToughFlex® Belt for Overband Magnets

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions. Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over…

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read MoreNecessity of Cleaning Magnetic Separators

When on site, our Technical Sales Engineers often take opportunity to check the installed magnetic separators. At many sites, this results in a conversation about the required cleaning frequency for a permanent magnetic separator such as a Drawer Filter Magnet, Plate Magnet, or Liquid Magnetic Separator. This is when captured ferrous metal is manually removed…

Read MoreElectro Suspension Magnet Preference for Compost Supplier

A leading UK compost supplier has replaced two permanent suspension magnets with Bunting’s electro suspension magnets. The additional power of electro suspension magnets enables enhanced separation of small ferrous metals such as nails. The supplier of compost assessed methods to improve the level of ferrous metal separation for two separate process lines. Previously installed were…

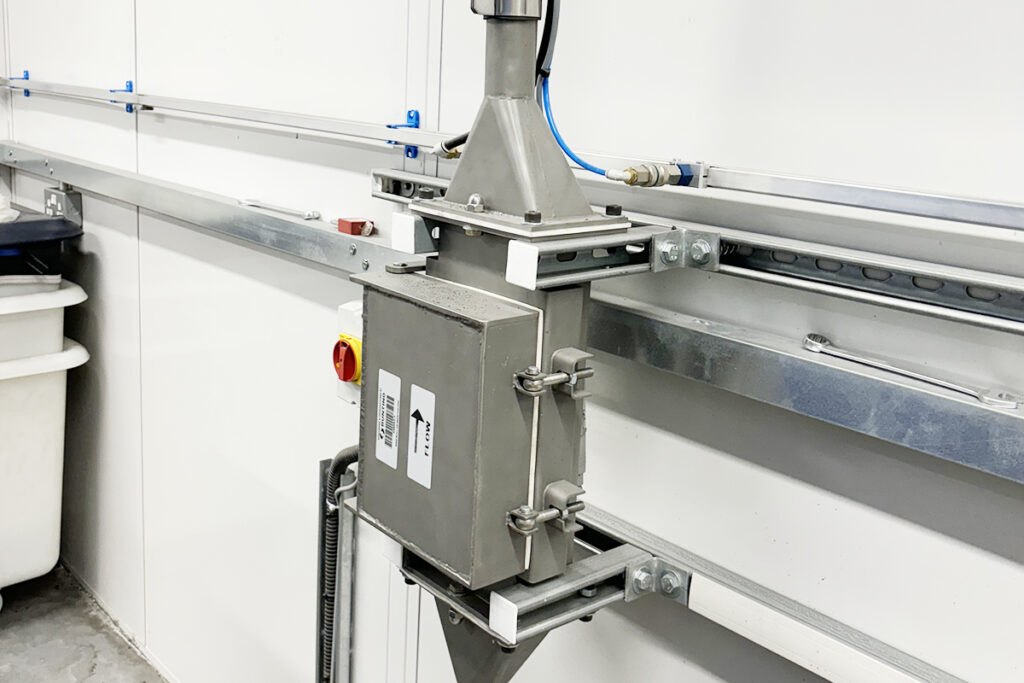

Read MoreNew FF Drawer Filter Magnet

Following a customer-driven redesign, Bunting’s new FF Series Drawer Filter Magnet is easily fitted into an extended range of granulators, injection moulding machines and other plastics manufacturing and processing plant, eliminating the need for customisation. Drawer Filter Magnets use powerful Neodymium tube magnets, arranged in a grid, to capture and extract ferrous particles from dry,…

Read MoreSingle, Twin and Tri Pole Overband Magnet Development

Bunting has developed three designs of Permanent Crossbelt Overband Magnet (PCB), with different magnetic polarity, to suit an ever-expanding range of applications. Overband Magnets are mounted over conveyors to separate ferrous metal from non-magnetic material and are commonly used in industries including mining, quarrying, recycling, and wood. The magnetic field of a Permanent Crossbelt Overband…

Read More