Mineral Processing

Ceramics UK 2019 Show Success

The last UK-based ceramics focused exhibition was staged in Telford, UK over twenty years ago. In July 2019, once again in Telford, the new Ceramics UK show once again thrust ceramics into the spotlight, providing the perfect showcase for the sector. Ceramics UK was co-located in Telford, UK with The Advanced Materials Show. Over twenty…

Read MorePaper Abstracts for Physical Separation Conference

The Physical Separation ’19 conference The physical separation conference organised by Minerals Engineering International (MEI), is held at the National Maritime Museum in Falmouth, Cornwall, United Kingdom on the 13th and 14th June 2019. The conference focuses on the application of physical methods to separate and concentrate minerals. At the conference, Dr Neil Rowson will be…

Read MoreRare Earth Roll or Induced Magnetic Roll

Comparing Two High Intensity Magnetic Separators High intensity magnetic separators remove ferro and para magnetic particles from dry non-metallic minerals. However, the design of the separation system dictates the final product purity and product losses. The two most common designs of dry high intensity magnetic separator are the Induced Roll (IMR) and the Rare Earth…

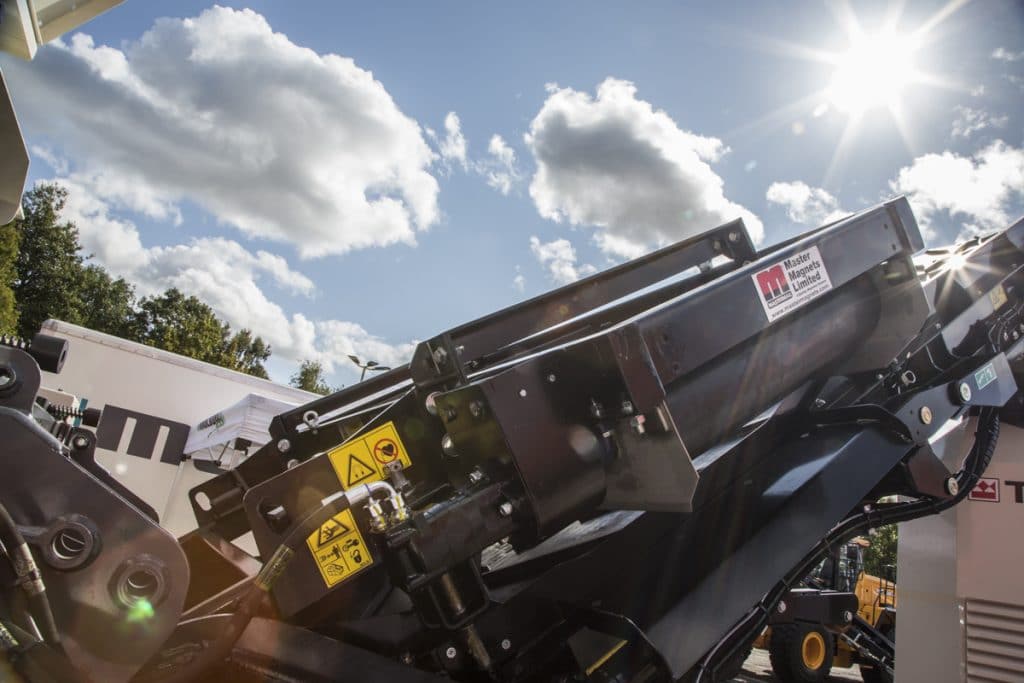

Read MoreNew Export Opportunities at Bauma 2019

Throughout the whole 7 days, the Bunting stand at Bauma 2019 buzzed with visitors. Mineral separation demonstrations on the Rare Earth Roll Magnetic Separator ignited curiosity and stimulated questions. The new ElectroMax Overband Magnet, proudly displayed at the front of the stand, drew visitors and the media. There was particular interest in the heavy duty,…

Read MoreTechnical Explanation of Rare Earth Roll Separator

The Rare Earth Roll Separator is one of the world’s most popular permanent magnetic separators used by mineral processors to separate paramagnetic minerals from dry materials. The Rare Earth Roll Separator is simple to install and use, whilst being exceptionally energy-efficient. The high-intensity magnetic strength enables the separation of very weakly magnetic minerals such as mica…

Read MoreMineral Processing & Magnetic Separators, Bauma 2019

The latest generation of high intensity Magnetic Separators will be on display on the Bunting Magnetics and Master Magnets stand (Hall B2 Stand 133) at Bauma 2019. The metal and mineral separators are used widely in the mineral processing, quarrying and recycling industries. Also, a new design of Magnetic Separator is being launched at the…

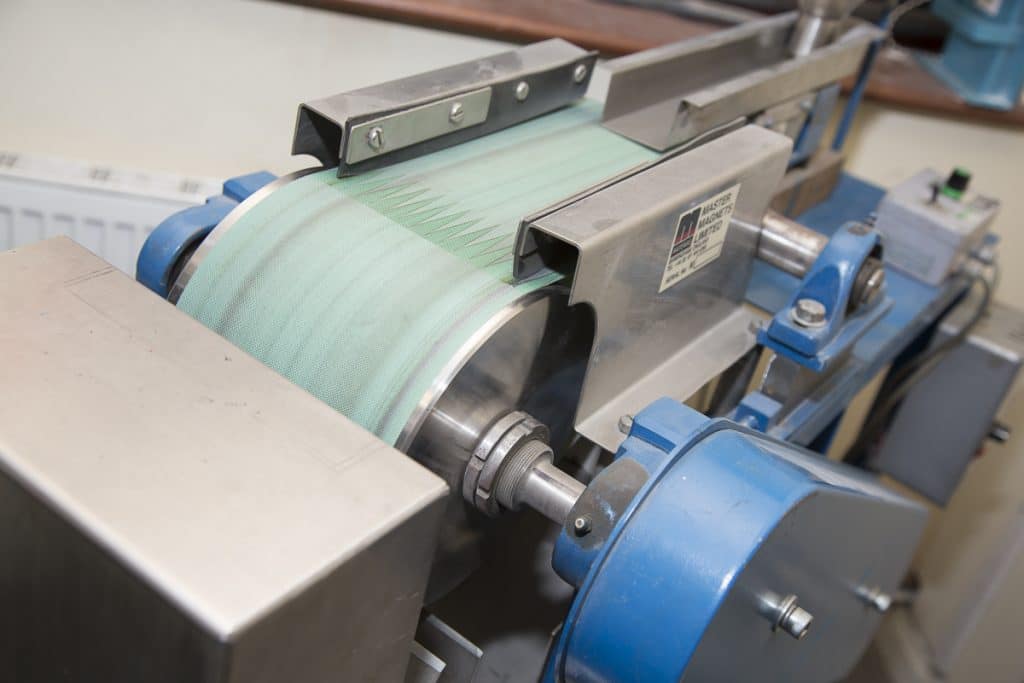

Read MoreMineral Processing Lab High Intensity Electromagnetic Filter

A high intensity Electromagnetic Filter has expanded the mineral testing capabilities in the Bunting-Redditch mineral processing laboratory. The Electromagnetic Filter is designed to remove fine iron and weakly magnetic materials from mineral slurries and ceramics slips and glazes. The new equipment expands the extensive range of high intensity magnetic separators already used in the test…

Read MoreMaster Magnets Sponsor Physical Separation 2019

Magnetic Separation – International Mineral Conference Master Magnets has been announced as one of the principle sponsors of the Physical Separation ’19 conference (13-14 June, National Maritime Museum, Falmouth, Cornwall, UK). Physical Separation ’19 is organised by Minerals Engineering International (MEI). Although chemical methods of concentration and extraction dominate the industry, the physical separation methods are ubiquitous. …

Read More2018 Review

A Look Back at our News & Blogs in 2018 2018 proved to be another exciting year. Despite the spectre of BREXIT, business overseas continued to flourish and grow. We attended a number of international exhibitions, securing orders on the stand. There have also been concerns on the UK mainland about waste management and especially…

Read MoreMagnetic Disc Separator for Processing Coltan

A Magnetic Disc Separator (MDS) has been manufactured and despatched to Nigeria for use in the processing of Coltan (a combination of columbite and tantalite). The Magnetic Separator is used in a process to primarily extract Tantalum. Tantalum is a key raw material in the manufacture of batteries for electric cars, mobile phones and other…

Read More