Mineral Processing

Wet High Intensity Magnetic Separation Testing

The electromagnetic laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) removes fine magnetics and para-magnetics from mineral slurries. Handling minerals in a slurry or suspension is preferable for many processors, especially when beneficiation involves wet processing. Additionally, a wet process often produces a better separation for very fine materials. In this educational video, Professor Neil Rowson…

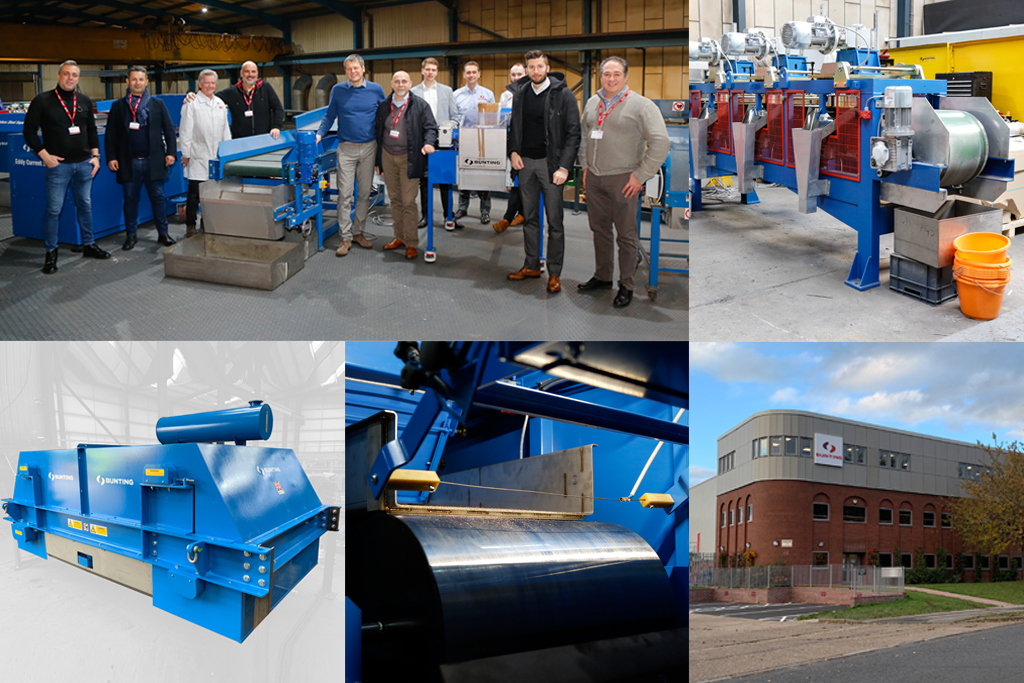

Read MoreBunting-Redditch 2020 Review

To state that 2020 has been challenging would be an understatement. The global Covid-19 pandemic has changed the way people live their lives, and businesses have had to adapt. Despite the difficulties, there has been plenty of positive news coming out of Bunting-Redditch. Throughout 2020, building work has continued on a major plant and office…

Read MoreChute Magnet Separator Checks Magnetic Susceptibility

The Chute Magnet Separator or Magnetic Slide is a simple but important laboratory-scale wet magnetic separator for any material test facility. This magnetic test equipment enables the assessment of a particle’s magnetic susceptibility, which provides the platform for further tests on specific wet magnetic separators. Wet magnetic separation techniques are employed when processing slurries (i.e.…

Read MoreKeeping Ceramic Tiles Iron Free

When fine iron and iron-bearing minerals contaminate the raw material used to produce ceramic tiles, the consequences are costly. Such iron contamination causes visual and structural defects as well as affecting the surface finish in terms of brightness and whiteness. Tiles failing final quality checks are commonly returned for recycling. Those passing the initial quality…

Read MoreInline Magnet Pros and Cons

The Inline Magnet is a versatile and popular magnetic separator used widely to capture tramp ferrous metal contamination. The non-obstructive design suits applications in many different applications including food processing and plastics. In this blog, we review the different designs and the Inline Magnet’s key advantages and disadvantages Inline Magnet Models The Inline Magnet is designed…

Read MoreMeasuring Magnetic Separator Power

A Magnetic Separator attracts, captures and holds magnetic particles. The magnetic strength needed to successfully separate such problematic ferrous metal contamination is commonly stated in a magnetic separator supplier’s quotation or specified in the tender. This ‘Magnetic Strength’ is usually referenced in terms of ‘Gauss’, a unit of measurement. However, as it is difficult to accurately measure…

Read MoreWhat is an Axial and Radial Magnetic Field?

Rotary Magnetic Separators, such as the Drum Magnet and Pulley Magnet, are designed with a specific type of magnetic field. The type of magnetic field is considered when looking at any application and when deciding which design will achieve a customer’s separation objective. For these rotary designs of magnetic separator, there are two types of magnetic…

Read MoreMagnetic Properties of Minerals

Magnetic properties of minerals

Read MoreDemonstrating the ElectroMax Overband Magnet’s Power

The ElectroMax Overband Magnet has proved extremely popular since the launch in May 2019. Shipments average at over one ElectroMax per month with an increasing number of mobile plant, mining and recycling companies turning to the air-cooled ElectroMax Electro-Overband Magnet as a high-performance, lightweight option to the traditional Permanent Overband Magnet. Technical information: Overband Magnets…

Read MoreElectroStatic Separation of Minerals

Article written by Neil Rowson, Professor of Minerals Engineering in the School of Chemical Engineering at the University of Birmingham Electrostatic phenomenon dates back to 600 – 700 B.C. when people noticed static electric effects (attraction of hair) when amber was rubbed with fur. Indeed, the word ‘electrostatic’ comes from the ancient Greek word ‘electron’…

Read More