Plate Magnet

Metal Removed from Plastic Regrind

The combination of a magnetic separator and metal detector is removing rogue metal contamination from recycled plastic regrind before the material is mixed into other raw materials used for the manufacture of plastic products including handles and hinges. At the plant, waste generated from plastics injection moulders and in the manufacturing process is reground for…

Read MoreNecessity of Cleaning Magnetic Separators

When on site, our Technical Sales Engineers often take opportunity to check the installed magnetic separators. At many sites, this results in a conversation about the required cleaning frequency for a permanent magnetic separator such as a Drawer Filter Magnet, Plate Magnet, or Liquid Magnetic Separator. This is when captured ferrous metal is manually removed…

Read MoreProtection Against Metal Contamination at Interpack 2023

Magnetic separators, metal detectors and x-ray foreign body detectors to identify and remove metal and other contamination prior to and after packing are the focus for Bunting at Interpack 2023 (4-10 May, Düsseldorf, Germany). On stand D66 in hall 11, Bunting will exhibit working metal separators such as high-strength rare earth Drawer Filters Magnets; conveyor-mounted…

Read MoreMetal In Food Alerts 2022

In 2022, the UK Food Standards Agency issued ten (10) alerts regarding metal-contaminated food products that had reached the public. This was up from five (5) in 2021. The metal-contaminated food products were supplied by companies at various stages in the food supply chain, including leading UK supermarkets such as Tesco and Co-Op, as well…

Read MoreApplication Review – Small Tramp Ferrous from Recycled Gypsum

The extensive range of magnetic separators means that there are often several options for any one application. However, the final selection is dependent on a number of variables including the available space, separation objective, and the critical nature of the separation. This particular project required the improved separation of tramp iron from conveyed recycled gypsum.…

Read MoreGetting Metal Out of Grain and Cereals

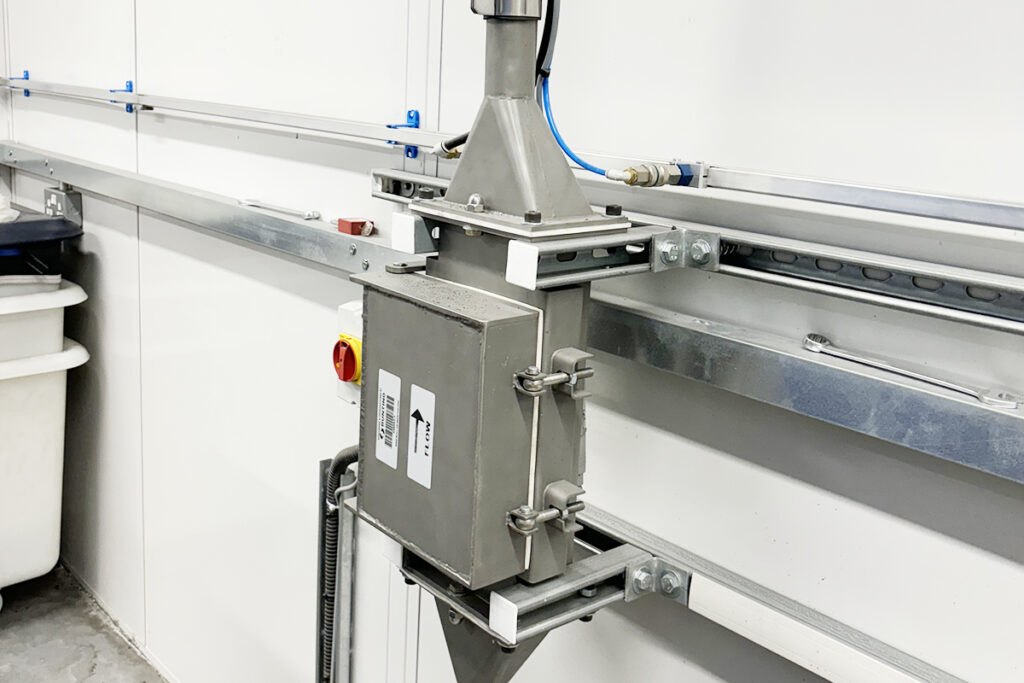

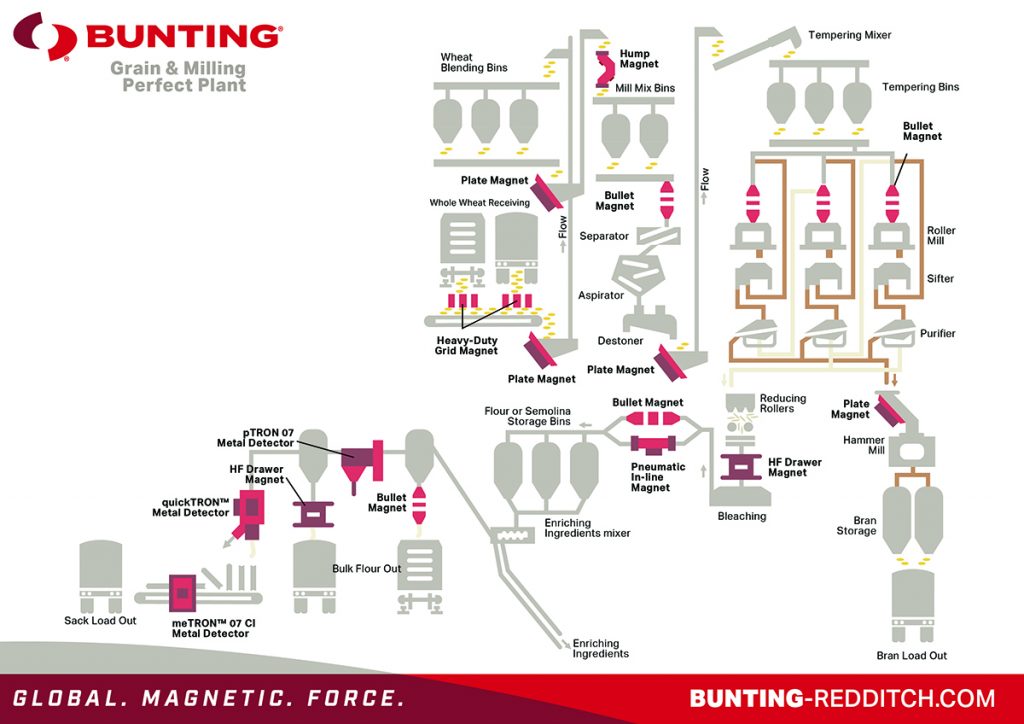

By the time grain and cereals have been collected and delivered to a Milling Plant, it is highly likely that there is metal contamination present. Removing that metal to prevent damage to processing equipment and produce the highest quality end-product is essential and achieved with a series of different designs of Magnetic Separators and Metal…

Read MoreFive Magnetic Separator Myths

Often ascertaining the best Magnetic Separator for any given application is not straightforward. To complicate the decision-making process further, many companies supplying magnetic separators provide a wealth of information such as Gauss levels and the amount of metal that the Magnetic Separator can actually capture. Such details are often difficult to verify and may even be meaningless. In this…

Read More3 Metal Parts Contaminating Plastic Waste

Recycling plastic waste is challenging at the best of times. However, when contaminated with ferrous metals, recycling is hindered by equipment damage, production downtime and poor end product quality. Thankfully, installing the optimum magnetic separator ensures that such ferrous metal contamination is removed. In this article we look at three examples of ferrous metal contamination…

Read MoreSeparating Fine Iron from Powders

Effectively separating fine iron from dry powders is often challenging. Even the strongest magnetic separator may fail to successfully remove the magnetic particles. In order to find a successful solution, it is important to understand the way fine materials behave. Only then is it possible to determine the optimum method to cleanse a powder of…

Read MoreMetal Removal when Recycling Rubber Tyres

Successfully removing metal from rubber (originating from the metal wire in a tyre) when recycling tyres is critical, especially as rogue metal can cause injury to horses and children who run and play on the recovered rubber crumb. Although each tyre recycling plant is different, here is a guide to the common types and location…

Read More