Equipment

Hillhead Success for Bunting

The Hillhead quarrying, construction and recycling show (Buxton, UK, 25-27 June, 2024) was blessed with a decent spell of weather for the throngs of international visitors. Bunting’s ideally located stand, on the downslope towards the pavilion, was busy for the whole 3-days. Bunting has exhibited at Hillhead for decades, with metal detectors, magnetic separators and…

Read MoreBunting ElectroMax-Plus Protects Aggregate Crushers

A UK construction materials company installed an ElectroMax-Plus Overband Magnet to remove tramp ferrous metal from quarried material prior to crushing. Bunting specified, designed and built the powerful electromagnetic Overband Magnet at their UK manufacturing facility in Redditch. The ElectroMax-Plus Installation The ElectroMax-Plus Overband Magnet is installed at magnesium limestone quarry in Derbyshire, United Kingdom. …

Read MoreHigh Intensity Magnetic Separation at UK Mining Conference

High intensity magnetic separation and enhanced tramp metal magnetic separation is the focus for Bunting at the UK Mining Conference in Cornwall, UK (12-13 June 2024). High-profile delegates including investors, brokers, operators, and the mining supply chain attend the two-day conference, held at the historic Princess Pavilion in Falmouth in Cornwall. The recent rise in…

Read MoreMetal Separation at E-Waste World Conference 2024

Maximising metal separation and recovery from e-waste is the focus for Bunting on stand C60 at the E-Waste World Conference and Expo (26-27 June 2024, Messe Frankfurt, Germany). The Bunting team is joined on the stand by their local representative Marcel Graef from 3SMI. The global production of e-waste rose to 62 million tonnes (Mt)…

Read MoreBunting Attracts Crowds at IFAT 2024

There was a constant stream of visitors on Bunting’s stand at the IFAT Munich 2024 (13-17 May). Bunting’s multinational team from the UK, Germany, Italy, and the USA talked metal separation with visitors from around the world. IFAT is the world’s leading trade fair for water, sewage, waste and raw materials management. “IFAT provided the…

Read MoreElectroMax Overband Magnet Power at Hillhead 2024

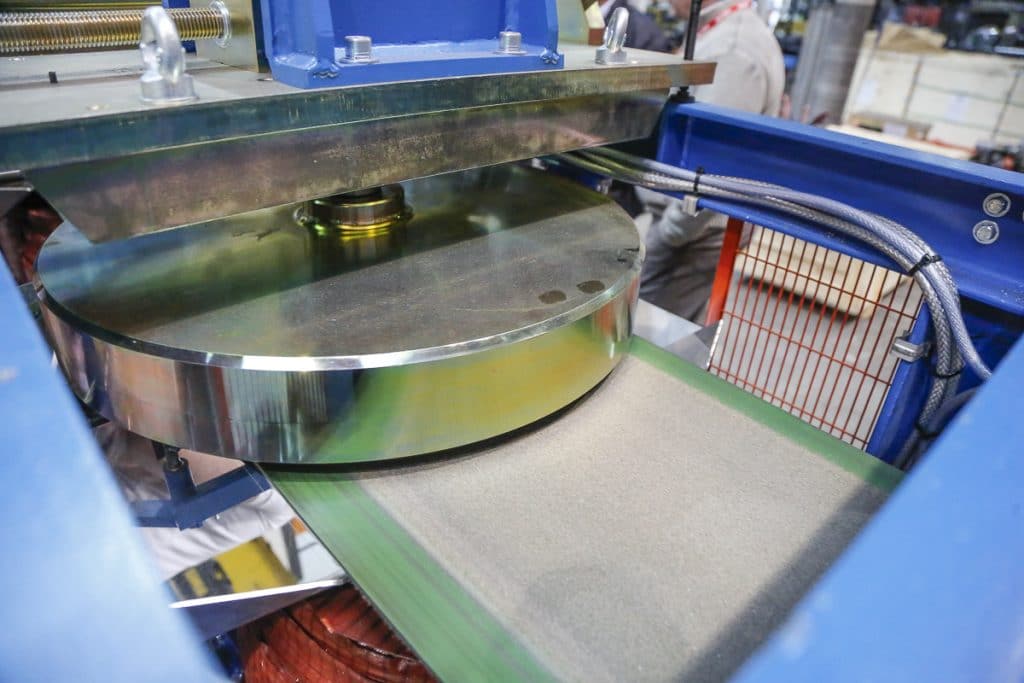

The compact but powerful characteristics of the ElectroMax Overband Magnet are highlighted on Bunting’s stand C9 at the Hillhead quarrying, construction and recycling show (25-27 June, 2024). The ElectroMax is accompanied on the stand by the TN77 and meTRON 05D metal detectors, and a permanent suspension magnet. Solving Metal Separation Problems at Hillhead Magnetic separators…

Read MoreOverband Magnet Extended by 56%

A challenging installation on mobile recycling plant led to Bunting designing and building a Permanent Overband Magnet with a magnet block over 56% longer than normal. The model PIL Overband Magnet was extended from the standard length of 1100mm to 1725mm. Permanent Overband Magnets are suspended over conveyor belts transporting material to separate ferrous metals,…

Read More120 ElectroMax Overbands Sold in Five Years

April 2024 marks five years since the launch of the ElectroMax Overband Magnet and, in that period, Bunting has built and shipped 120 units for a value exceeding £3 million. The ElectroMax Overband Magnets provide the enhanced separation of ferrous metal from conveyed material in recycling plants, mines, and quarries, bulk handling terminals, and power…

Read MoreBoosted Metal Separation with ElectroMax-Plus Overbands at W Maw

General skip waste recycler W Maw Recycling Ltd has installed two Bunting ElectroMax-Plus Overband Magnets at their Rotherham operation in the United Kingdom. The powerful electromagnetic ElectroMax-Plus Overbands replaced permanent overband magnets to separate larger and heavier ferrous metal that could damage shredders and other process plant. Replacing Permanent Overband Magnets with the ElectroMax W…

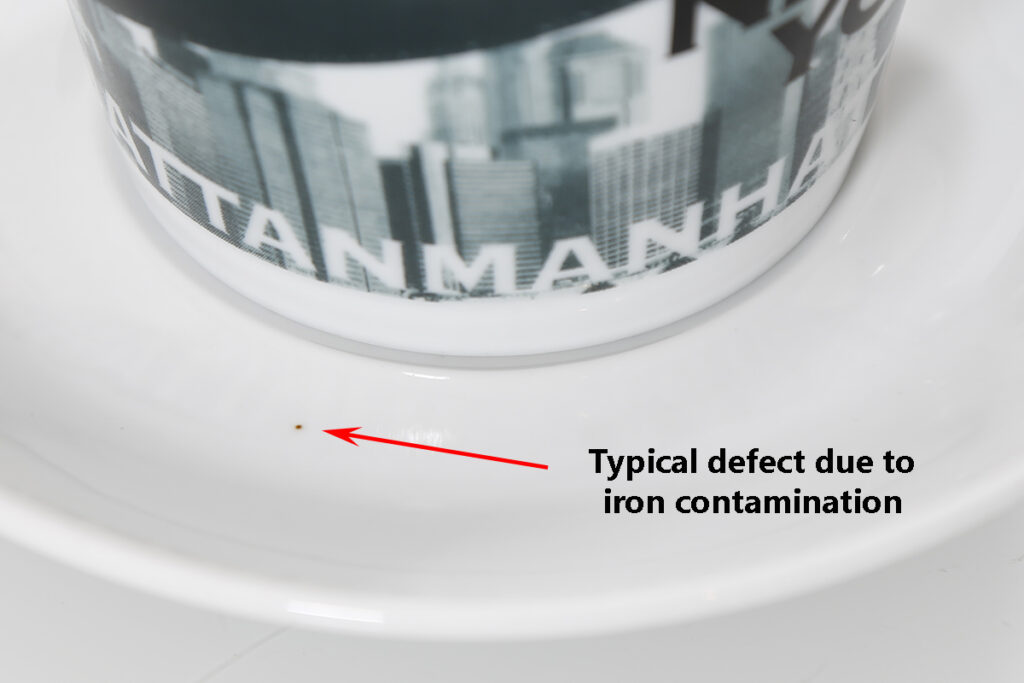

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read More