Equipment

Mineral Processing Lab High Intensity Electromagnetic Filter

A high intensity Electromagnetic Filter has expanded the mineral testing capabilities in the Bunting-Redditch mineral processing laboratory. The Electromagnetic Filter is designed to remove fine iron and weakly magnetic materials from mineral slurries and ceramics slips and glazes. The new equipment expands the extensive range of high intensity magnetic separators already used in the test…

Read MoreInternational Electronics Recycling Congress 2019

Talking Magnetic Separators at IERC 2019 The Bunting Magnetics and Master Magnets team are exhibiting (stand 17) at this month’s 18th International Electronics Recycling Congress IERC 2019 (January 16-18, Salzburg, Austria). IERC 2019 is an important biennial event on the recycling industry calendar, bringing together international producers, recyclers, equipment manufacturers, recycling associations, refurbishers, standards bodies, NGOs,…

Read More2018 Review

A Look Back at our News & Blogs in 2018 2018 proved to be another exciting year. Despite the spectre of BREXIT, business overseas continued to flourish and grow. We attended a number of international exhibitions, securing orders on the stand. There have also been concerns on the UK mainland about waste management and especially…

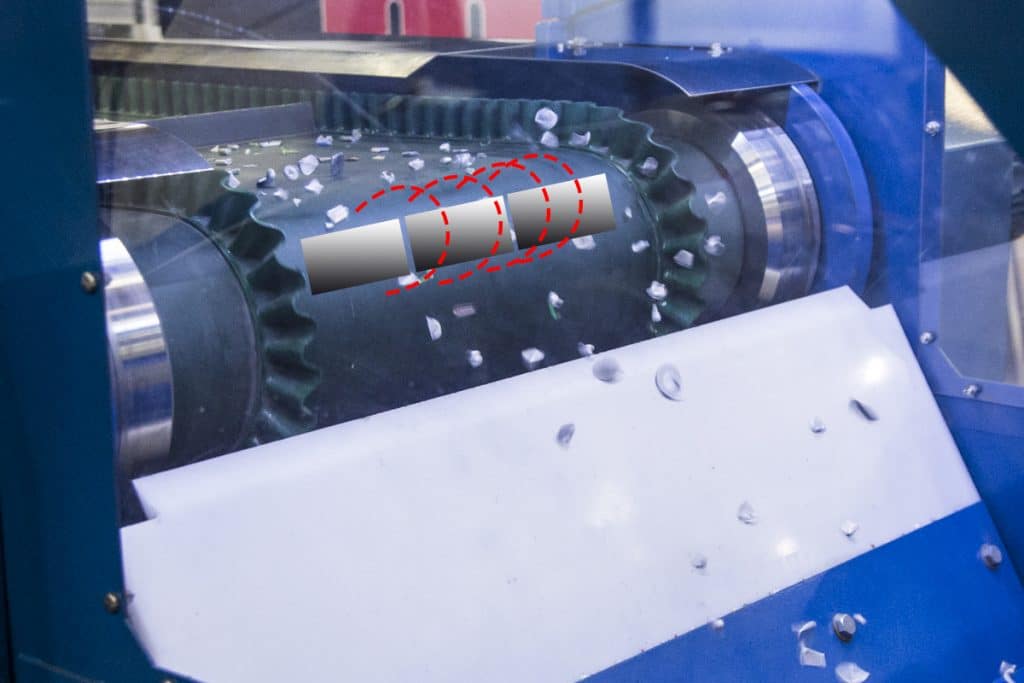

Read MoreEddy Current Separator Magnetic Poles

2nd of 5 Technical Articles: Reviewing Eddy Current Separator Performance More is always better. Or is it? In the second of our technical articles reviewing the design of Eddy Current Separators, we look at the importance of the number of magnetic poles. Does a magnetic rotor with 42 magnetic poles enable a better separation than…

Read MoreElectro Overband Magnet Selection

The Bunting range of Electro Overband Magnets is extensive. Selecting the optimum design of Electro Overband Magnet to perform a specific separation task is critical to the successful separation of tramp metal. Poor magnet selection could result in damage to processing equipment or a reduction in product quality. To aid the correct selection, Bunting’s team…

Read MoreMagnetic Disc Separator for Processing Coltan

A Magnetic Disc Separator (MDS) has been manufactured and despatched to Nigeria for use in the processing of Coltan (a combination of columbite and tantalite). The Magnetic Separator is used in a process to primarily extract Tantalum. Tantalum is a key raw material in the manufacture of batteries for electric cars, mobile phones and other…

Read MoreEddy Current Separator Rotor Speed Review

Eddy Current Separator Rotor Speed Review

Read MoreTechnical Explanation of the Magnetic Disc Separator

The origins of the Magnetic Disc Separator date back to the early 1900s. Although manufacturing techniques have significantly changed and more advanced machines have now been incorporated, the basic function design remains virtually the same. The Magnetic Disc Separator is widely used to ensure an accurate separation of dry minerals that have varied magnetic susceptibilities.…

Read MoreMagnetic Separators and Magnetic Separation Equipment

What is Magnetic Separation? Magnetic Separation is one of the most common and important physical separation techniques and there are many varieties of magnetic separation equipment available. The basic concept of a Magnetic Separation is that magnetically susceptible particles or bodies are separated from non-magnetic particles. However, the simplicity stops there. To enable different levels…

Read MoreMagnetic Separators For Mineral Processing

Magnetic separators can be found in most mineral processing operations, especially those processing non-metallic minerals and magnetic ores. This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the -15mm, +45 micron size range). Principles of Magnetic Separators There…

Read More