Equipment

New Export Opportunities at Bauma 2019

Throughout the whole 7 days, the Bunting stand at Bauma 2019 buzzed with visitors. Mineral separation demonstrations on the Rare Earth Roll Magnetic Separator ignited curiosity and stimulated questions. The new ElectroMax Overband Magnet, proudly displayed at the front of the stand, drew visitors and the media. There was particular interest in the heavy duty,…

Read MoreElectroMax Overband Magnet Launched At Bauma

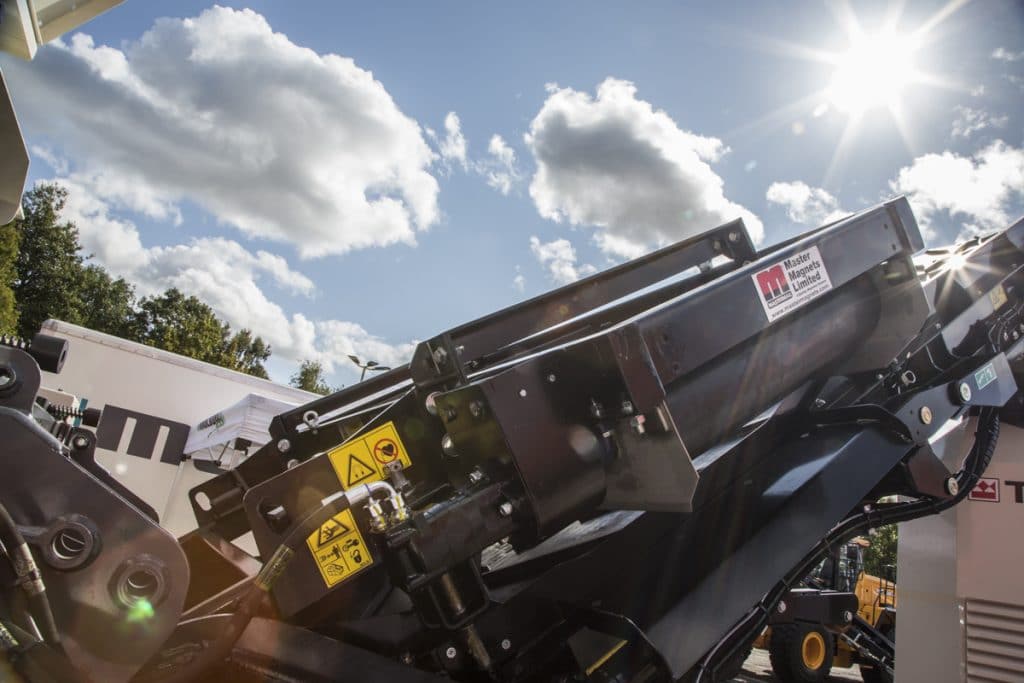

Master Magnets ElectroMax Overband Magnet at Bauma Master Magnets is launching a new low-profile Electro Overband Magnet called the ‘ElectroMax’ at Bauma 2019 (Munich, Germany 8-14 April, 2019 – Stand 133 in Hall B2). The ElectroMax range is 185% stronger than equivalent Permanent Overband Magnets and also 25% lighter. The development in response to customer’s…

Read MoreTechnical Explanation of Rare Earth Roll Separator

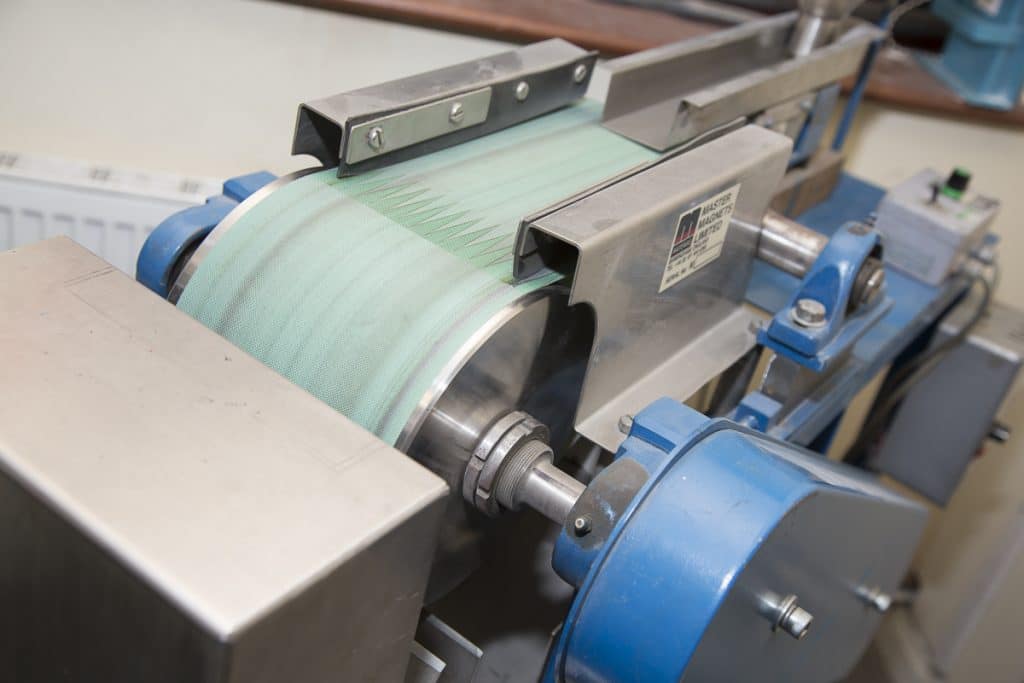

The Rare Earth Roll Separator is one of the world’s most popular permanent magnetic separators used by mineral processors to separate paramagnetic minerals from dry materials. The Rare Earth Roll Separator is simple to install and use, whilst being exceptionally energy-efficient. The high-intensity magnetic strength enables the separation of very weakly magnetic minerals such as mica…

Read MoreMetal Recovery from Incinerator Bottom Ash

Burning any sort of waste produces an ash by-product often called ‘incinerator bottom ash’ or ‘furnace ash’. Commonly, this ash contains a high proportion of recoverable metal. This mix of ferrous and non-ferrous metal is recovered using Magnetic Separators and Eddy Current Separators. Ferrous Metal Recovery For one of our latest projects, we undertook extensive…

Read MoreTwo High Sensitivity Metal Detectors For Immediate Sale

We presently have two high sensitivity Metal Detectors in stock ready for immediate sale. This design of Metal Detector offers complete protection against metal contamination in high risk products such as food (both loose and packaged) and pharmaceuticals. Both available Metal Detectors are the model MDE-C. “C” stands for the compact range, which has an all-in-one…

Read MoreMineral Processing & Magnetic Separators, Bauma 2019

The latest generation of high intensity Magnetic Separators will be on display on the Bunting Magnetics and Master Magnets stand (Hall B2 Stand 133) at Bauma 2019. The metal and mineral separators are used widely in the mineral processing, quarrying and recycling industries. Also, a new design of Magnetic Separator is being launched at the…

Read MoreLarge Pulley Magnets for Mining Project

Two 1.2 metre diameter Pulley Magnets have been manufactured and supplied to a mining operation in Sweden. The Pulley Magnets are used to extract large tramp metal from iron ore prior to crushing and screening. Removing the tramp metal protects the other processing equipment and prevents damage to conveyors. The mining operation originally purchased three…

Read MoreNew Recycling Test Facility

Following an increase in the demand for material testing, Bunting has constructed a new recycling test facility at their manufacturing operation in Redditch. Initially, the facility will house two models of Stainless-Steel Magnetic Separator and an Eddy Current Separator. New Recycling Test Facility “We are seeing an increase in the number of controlled material tests,”…

Read MoreSkip Hire Magazine Visits Master Magnets

A visit from Scott Golland and Richard Hollis from Skip Hire Magazine provided us with an ideal opportunity to update them on exciting developments at our Redditch plant. Following announcing a 25% growth in sales in 2018 on 2017, we have started the year strongly with three (3) orders for Stainless Steel Magnetic Separators. Skip Hire…

Read More3 Stainless Steel Magnetic Separators Sold In January 2019

Orders for 3 SSSC model Stainless Steel Separators The success of 2018 flowed into January 2019 with three orders for SSSC model Stainless Steel Magnetic Separators. All three orders are for different customers with specific metal separation objectives. “This is a fantastic way to start 2019,” said Dave Hills, Head of Sales. “Interest in the…

Read More