Equipment

A Great Recycling History

There has never been a greater focus on recycling and reusing waste materials. Many experts claim that our waste problem is related to the modern ‘throw-away’ society. Convenience, aligned to our busy lifestyle, has driven up the need for quicker and easily-accessible goods. However, we have an incredible recycling history. Much can be learnt from…

Read MoreHigh Intensity Magnetic Separator Optimises Copper Recycling

Around 50% of copper used in Europe is obtained from recycling rather than newly mined ore (International Copper Study Group – ICSG). Indeed, copper is widely regarded as one of most recycled engineering metals with much of the world’s globally mined copper, some 0.32 trillion kilogrammes, still in circulation. In a typical home there is…

Read MoreMetal Recovery from Electric Vehicles

Click here to see our solutions for metal recovery from Electric Vehicles Mining the Urban Environment The anticipated global increase in production and consumption of electronic goods and electric vehicles puts a huge strain on raw material reserves. Subsequently, the focus has turned from mining raw materials to reclaiming, reusing and recycling secondary materials. This…

Read More6 Inline Magnets for Plastics Producer

Six (6) Inline Magnetic Separators (PIMS) are due to be installed in a UK plastic production facility. The project originated from a discussion at the Interplas exhibition in 2017. The Inline Magnetic Separator offers great versatility with ease of installation and maintenance. Inside the tube-like body is a strong Plate Magnet. This ensures that there is no restriction to…

Read MoreMetal Removal when Recycling Rubber Tyres

Successfully removing metal from rubber (originating from the metal wire in a tyre) when recycling tyres is critical, especially as rogue metal can cause injury to horses and children who run and play on the recovered rubber crumb. Although each tyre recycling plant is different, here is a guide to the common types and location…

Read MoreMagnetic Disc Separator Processes Beach Sands

Bunting’s latest Magnetic Disc Separator (MDS) is for processing and separating key minerals from a beach sands deposit. The three-stage Magnetic Disc Separator is destined for a mineral processing operation in Africa. The Magnetic Disc Separator Magnetic Disc Separators (MDS) enable an accurate separation of minerals with varied magnetic susceptibilities. Typically, a Magnetic Disc Separator…

Read MoreSpecial Offers for Global Recycling Day

The Global Recycling Foundation created the Global Recycling Day in 2018 to help recognise and celebrate the importance recycling plays in preserving our precious primary resources and securing the future of our planet. They state that ‘It is a day for the world to come together and put the planet first’. In 2020, Global Recycling…

Read MoreTramp Metal Removed from Reclaimed Kaolin

A major UK mineral processing company has installed two large Bullet Magnets to remove tramp ferrous metal from dry reclaimed kaolin. After initial discussions, Bunting conducted controlled tests in the Redditch Centre-of-Excellence. The reclaimed kaolin had a broad particle size range, with 95% below 250 microns. Iron contamination was approximately 1000ppm (although it could peak…

Read More3 Overband Magnet Installation Problems

The Permanent Overband Magnet is one of the most commonly used magnetic separators. Overband Magnets are found in most recycling plants recovering steel cans and other ferrous metals from a wide range of waste materials as well as in quarries (protecting crushers & screens) and on mobile plant (screens and crushers). However, incorrect installation leads…

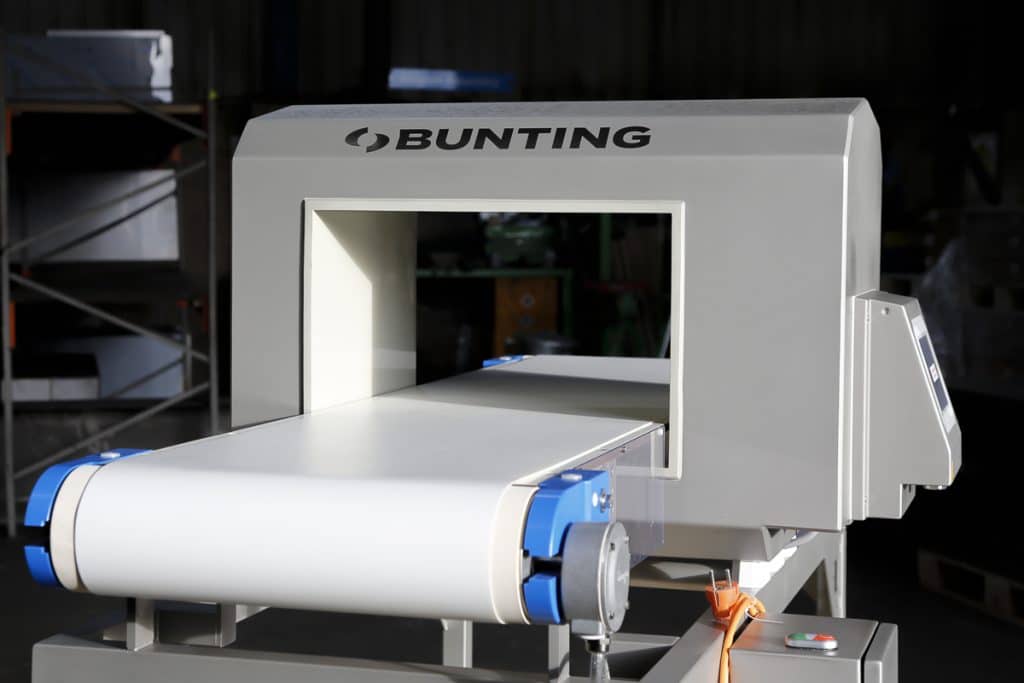

Read MoreThree High Sensitivity Metal Detectors for Nappies

An Egyptian paper mill has purchased three meTRON 07 CI Metal Detectors mounted on conveyors to detect metal in the tissue paper used as the filler in the manufacture of baby’s disposable nappies. The three meTRON Metal Detectors are identical in size and specification. Each has a 400mm wide belt passing through a 450mm wide…

Read More