Equipment

Metal Recovery from Aluminium Dross

An aluminium dross processing plant in the Middle East has purchased an Eddy Current Separator, Drum Magnet and ElectroStatic Separator to recover the valuable metal. The separation equipment was designed and built by Bunting at their Redditch manufacturing facility in the United Kingdom. Controlled Tests of Aluminium Dross Samples Aluminium dross is a byproduct of…

Read MoreApplication Review – Small Tramp Ferrous from Recycled Gypsum

The extensive range of magnetic separators means that there are often several options for any one application. However, the final selection is dependent on a number of variables including the available space, separation objective, and the critical nature of the separation. This particular project required the improved separation of tramp iron from conveyed recycled gypsum.…

Read MoreAdvanced Metal Separation at E-Waste World

The separation and recovery of fine and small metal is vital for the successful recycling of e-waste. On stand 314 at the E-Waste World Conference & Expo (30 November – 1 December 2021, Frankfurt Messe, Germany), Bunting is showcasing advanced metal separation technology specifically used in the recycling of electronics. Metal Recovery from WEEE Reclaiming…

Read MoreBunting Exhibiting at Ecomondo

With the Ecomondo Green Technology Expo encompassing the circular economy, the Bunting stand (hall A2 stand 007) focuses on material and metal recycling through separation to neodymium magnet recovery. Bunting is one of the world’s leading designers and manufacturers of magnetic separators for the recycling and waste industries. The group also provides magnet and magnetic…

Read MoreGetting Metal Out of Grain and Cereals

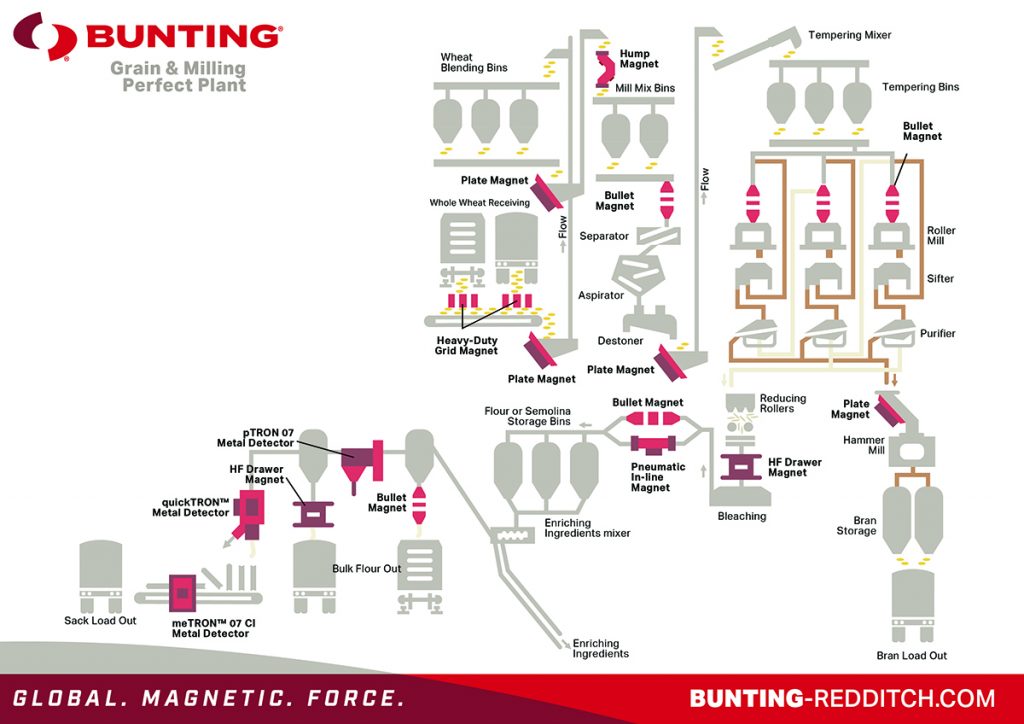

By the time grain and cereals have been collected and delivered to a Milling Plant, it is highly likely that there is metal contamination present. Removing that metal to prevent damage to processing equipment and produce the highest quality end-product is essential and achieved with a series of different designs of Magnetic Separators and Metal…

Read MoreNew Shredder Feeder Conveyor

The new Shredder Feeder Conveyor from Bunting-Redditch combines with either a magnetic separator or metal detector to protect a shredder or granulator from metal damage. Specifically designed for recycling plastics, both in-house regrind and from secondary sources, the Shredder Feeder Conveyor provides an even and controlled feed into a shredder or granulator. The design specifically…

Read MoreElectroStatically Cleaning Plastic Waste

With the ever-increasing amount of plastic waste collected for recycling, the ability to remove effectively contaminants including metal has never been more important. Often, contaminated plastic cannot be processed meaning that landfill or energy-to-waste are the only options. The ElectroStatic Separator significantly expands the range of product recycling possibilities, enabling the removal of very small…

Read MoreNew Bunting-Redditch Customer Experience Centre

Bunting’s newly extended manufacturing facility in Redditch, UK houses a world-leading testing and laboratory centre. The new Customer Experience Centre focuses on material separation with a wide range of high-intensity magnetic separators, eddy current separators and a revolutionary electrostatic separator. Complete Material Test Centre At the Bunting-Redditch material separation Customer Experience Centre is an extensive…

Read MoreTraining Future Metal Recyclers from EMR

Students, on a year’s work placement with European Metal Recycling (EMR), attended a training day at Bunting’s Redditch plant assessing the latest magnetic, eddy current and electrostatic separators. The training illustrated the importance of optimising material separation in the drive towards increasing secondary material recycling rates. EMR is a global leader in sustainable materials, investing…

Read MoreMagnetic Separators for CRS Overseas Recycling Plant

Bunting-Redditch has completed the manufacture and supply of three (3) magnetic separators and one (1) eddy current separator to recover metals in an overseas recycling plant designed and installed by CRS NI Ltd. CRS NI (Complete Recycling Systems) is a leading player in the UK waste processing market, designing and manufacturing bespoke Material Recycling Facilities…

Read More