Grate Magnet

Getting Metal Out of Beer

Thankfully, it is very unlikely that you will ever find a piece of metal in your glass of beer. However, when tramp metal (in the form of screws, nails, broken process plant, etc.) is accidentally introduced during the brewing process, it damages processing equipment and can even affect the taste of the beer. In this…

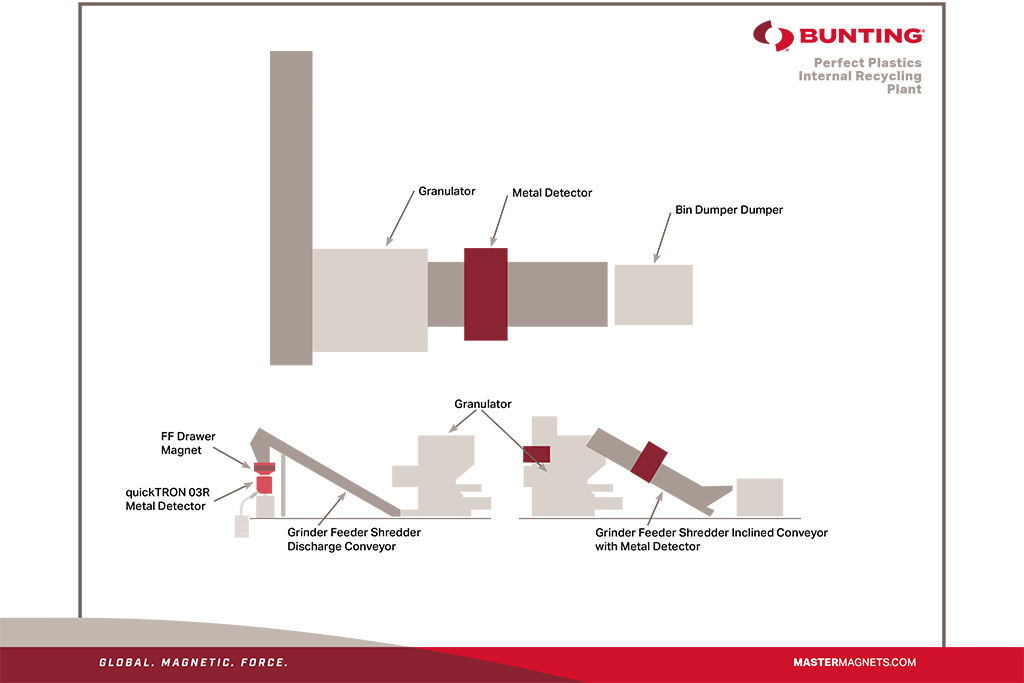

Read MoreEnsuring In-House Plastic Recycling Purity

When re-processing in-house plastic rejects and waste, the purity of the final recycled plastic mix must be equal or at least very close to the original raw material. Whether the re-processed plastic is for in-house use or as regrind for resale, the removal of any metal contamination is critical. Successful removal of metal contamination from…

Read MoreKeeping Ceramic Tiles Iron Free

When fine iron and iron-bearing minerals contaminate the raw material used to produce ceramic tiles, the consequences are costly. Such iron contamination causes visual and structural defects as well as affecting the surface finish in terms of brightness and whiteness. Tiles failing final quality checks are commonly returned for recycling. Those passing the initial quality…

Read MoreKeeping Ceramic Tableware Iron Blemish Free

Fine iron and iron-bearing minerals cause visual and structural defects in ceramic tableware. Such contamination appears as small dark spots on the surface or is hidden within the body and causes premature cracking of the ceramic. The cup, saucer or plate is then either rejected or reworked. Iron contamination The problem of iron contamination is…

Read MoreSeparating Fine Iron from Powders

Effectively separating fine iron from dry powders is often challenging. Even the strongest magnetic separator may fail to successfully remove the magnetic particles. In order to find a successful solution, it is important to understand the way fine materials behave. Only then is it possible to determine the optimum method to cleanse a powder of…

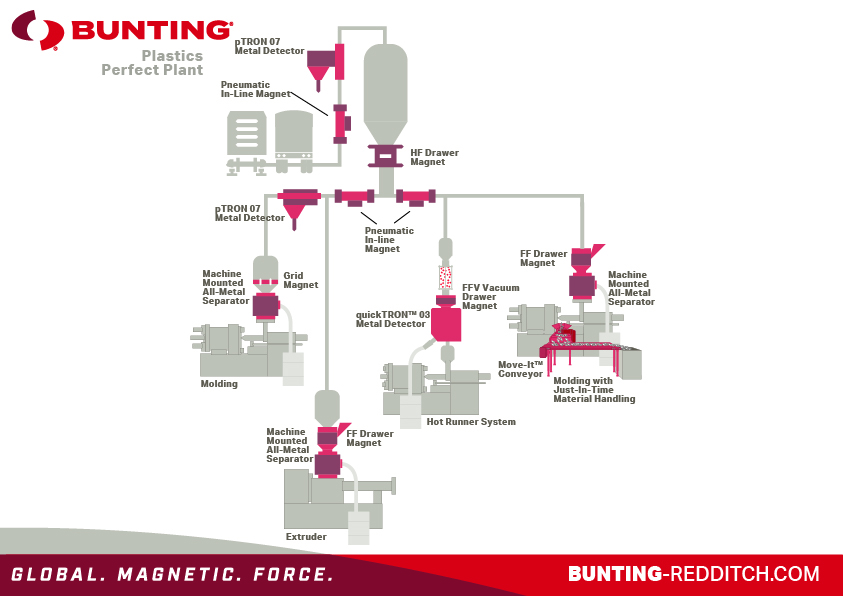

Read MoreMetal Separator Locations in a Plastics Plant

Determining the best location to remove metal in a Plastics Processing plant can be difficult. To assist plastics engineers, Bunting has released a Typical Plant Flowsheet showing optimum locations for metal separators. This blog focuses on the locations, designs and types of Magnetic Separator and Metal Detector commonly used in plastics plants. A Typical Flowsheet On the flowsheet, the…

Read MoreMagnetic Separators and Metal Detectors at VICTAM 2019

Metal contamination is a common problem in the animal feed and grain industries. Practical and proven solutions will feature on stand A029 at the VICTAM International 2019 exhibition (Cologne, Germany June 12 – 14). The range of Master Magnets and Bunting Magnetic Separators and Metal Detectors both identify and capture problematic metal that is potentially…

Read More