Suspension Magnet Electro

Magnetic Separation in Mining and Mineral Processing

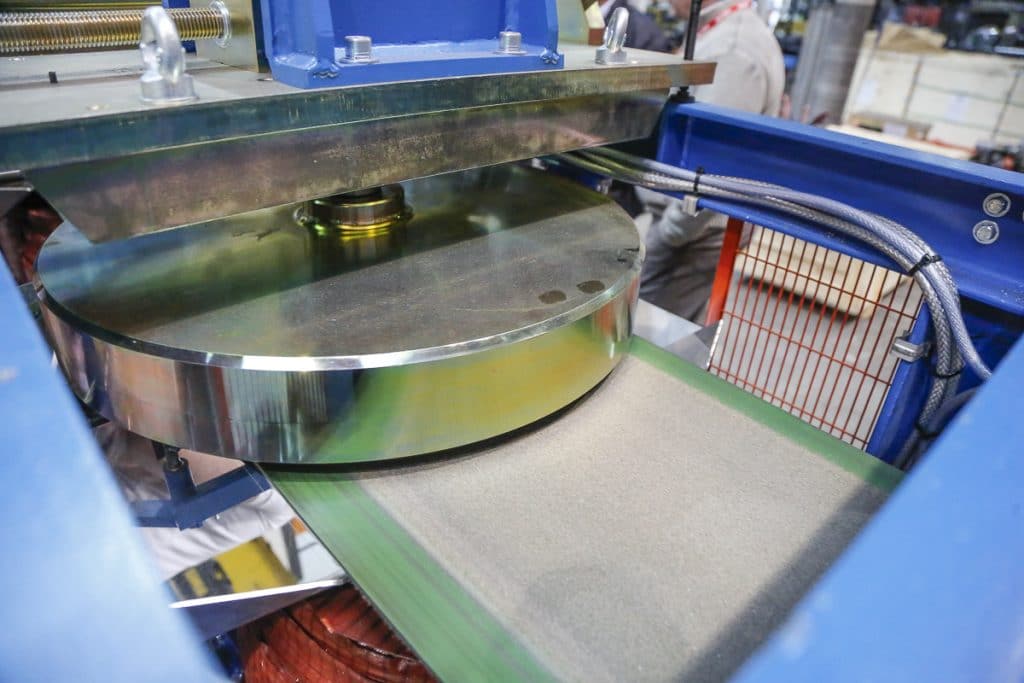

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals. Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. …

Read MoreSolving Quarrying and Mining Tramp Metal Problems

Tramp metal exists in all mining and quarrying operations. The problematic contamination is difficult to avoid. The nature of mining and quarrying – extracting ore and aggregate using large heavy equipment – results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage…

Read MoreElectro Suspension Magnet Preference for Compost Supplier

A leading UK compost supplier has replaced two permanent suspension magnets with Bunting’s electro suspension magnets. The additional power of electro suspension magnets enables enhanced separation of small ferrous metals such as nails. The supplier of compost assessed methods to improve the level of ferrous metal separation for two separate process lines. Previously installed were…

Read MoreAtherton Material Handling Installs Bunting Suspension Electro Magnet

Atherton Material Handling has installed a Bunting Suspension Electro Magnet at a calcium carbonate quarry in Melton, UK. The Suspension Electro Magnet removes tramp ferrous metal prior to a metal detector, reducing the number of metal detection trips and increasing productivity. Atherton Material Handling originally contacted Bunting to find a solution to the problem of…

Read MoreMagnetic Metal Free Areas under Overband Magnets

A common question asked when a client is installing an Overband Magnet or Suspension Magnet is whether the conveyor idlers, frame and housing could become magnetically induced. When installed suspended above a conveyor, the Overband Magnet and Suspension Magnet work by projecting a magnetic field down and through material transported on a conveyor. This magnetic…

Read MoreBunting Buzzing at Hillhead 2022

The sun shone and the crowds filled the quarry at Hillhead 2022 (21-23 June, Hillhead Quarry, Buxton, UK). The return of the UK’s largest quarrying, construction and recycling exhibition attracted visitors from across the world. At Hillhead, Bunting was displaying magnetic separators, including an ElectroMax Overband Magnet and Permanent Suspended Magnet, as well as a…

Read More40-Year Old Hillhead Still Attracts Bunting

The first Hillhead was held in 1982 and over those 40 years Bunting has manufactured and supplied thousands of magnetic separators and metal detectors for use in the aggregate and recycling industry. Once again, Bunting is exhibiting at the 2022 show (21-23 June, Hillhead Quarry, Buxton, UK), helping companies solve metal separation and detection problems…

Read MoreMagnetic Separator Air-Gap Explained

The ‘Air Gap’ plays a key role in the performance of a Magnetic Separator. In all magnetic separators, there is a gap between the magnet material or electromagnetic coil and the targeted particle. This ‘air-gap’ could be actual air or a non-metallic material such as stainless-steel or a rubber belt. When assessing an application, our…

Read MoreEddy Current Separator and ElectroMax Sales Growth in 2021

The demand for metal separators increased in 2021 on 2020, with exceptional growth in sales of both Eddy Current Separators and ElectroMax Overband and Suspension Magnets. Sales growth followed an expansion in representation in overseas markets and increasing manufacturing capacity at Bunting’s Redditch facility in the UK. At the Redditch manufacturing plant, Bunting specialise in…

Read MoreThe Crusher’s Arch Enemy – Tramp Metal

Crushing quarried aggregate is a key process stage of most quarries and when recycling demolition waste. Effectively protecting the crusher from rogue tramp metal damage prevents production losses and repair costs. The wide range of available crushing technology enables the production of optimally sized aggregate. Whereas Jaw and Gyratory designs commonly feature as primary crushers,…

Read More