Electro Magnetic Filter

Magnetic Separation in Mining and Mineral Processing

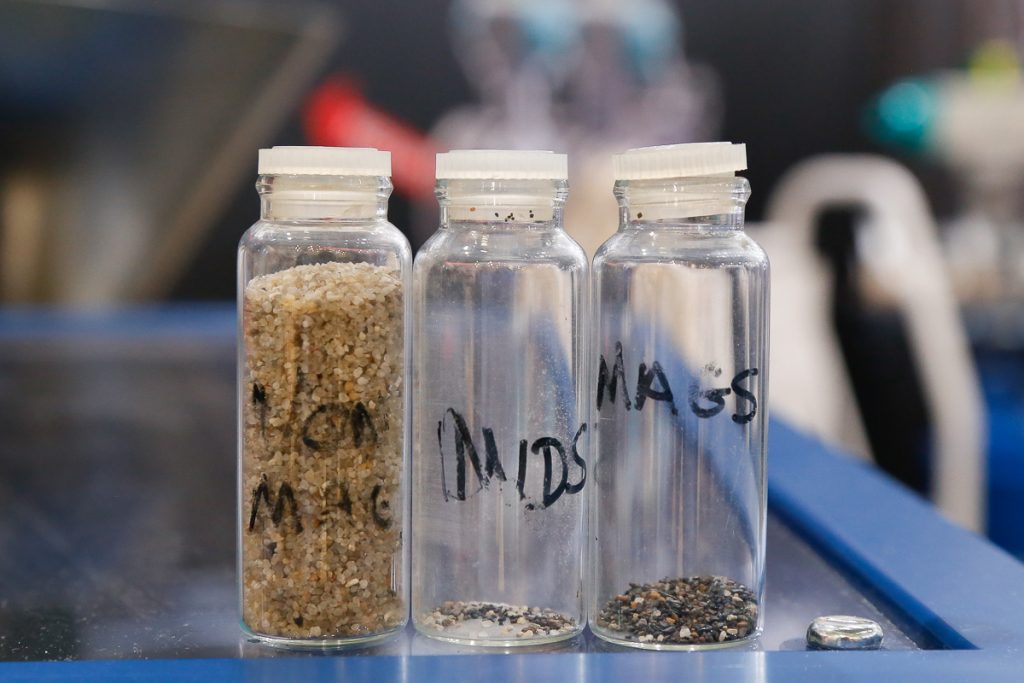

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals. Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. …

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

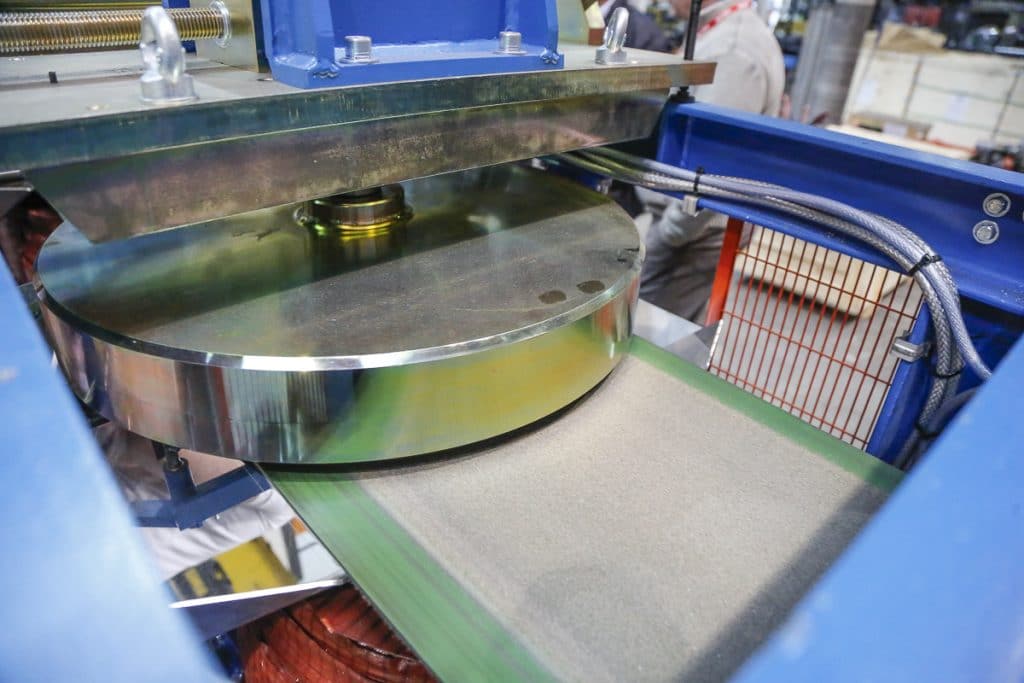

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreHigh Intensity Magnetic Separation at XVIII ECerS

The XVIIIth Conference of the European Ceramic Society takes place in Lyon, on 2-6 July 2023. On stand 19, Bunting is highlighting the necessity of using high-intensity magnetic separators to remove iron, iron-bearing and paramagnetic minerals to reduce defect rates and improve surface brightness. Paramagnetic Minerals and Fine Iron Contamination Materials used in the manufacture…

Read MoreBunting-Redditch 2022 Review

After a very optimistic start to 2022, the year presented the world with new challenges to overcome. Two years of negotiating the choppy waters of a pandemic was replaced by rising energy prices, material shortages and price rises, and increased interest rates; all sparked by the globally-condemned invasion of the Ukraine by Russia. Despite the…

Read MoreElectro Magnetic Filter for European Ceramics Producer

A leading German ceramic manufacturer is cleaning ceramic glaze with a high-intensity Electro Magnetic Filter designed and manufactured by Bunting. The successful removal of fine magnetics reduces finished product rejects and increases surface brightness. High-Intensity Electro Magnetic Filters The Electro Magnetic Filter provides one of the most effective methods of removing problematic fine iron and…

Read MoreHigh-Intensity Magnetic Separators at Ceramitec

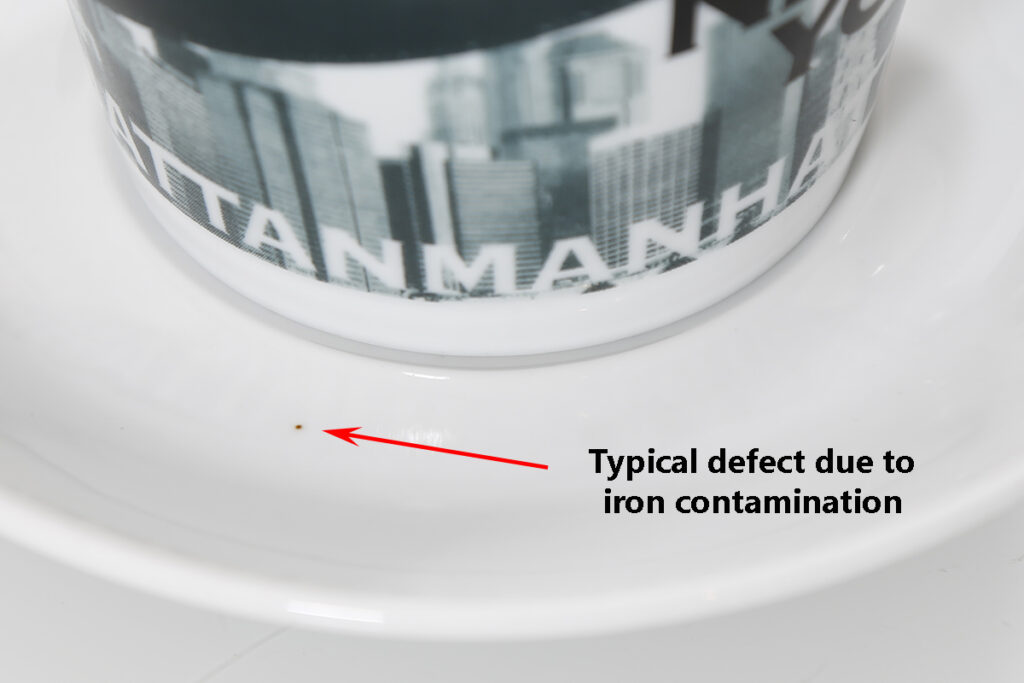

High-intensity magnetic separators play a key role in the manufacture of ceramics and the processing of ceramic raw materials, as highlighted at Ceramitec 2022 on Bunting’s stand (on stand C1:511). Keeping Ceramics Iron-Free Fine iron and magnetic minerals cause defects in any ceramic product, whether that is tableware, sanitaryware, tiles or technical ceramics. The iron…

Read MoreElectromagnetic Filters for Ceramics

Since the first ceramics were produced, iron and iron-bearing minerals have caused defects. The problematic minerals occur naturally in the raw materials, with additional fine iron accidentally introduced during transportation, storage or processing. Effective removal often involves several stages of magnetic separation. However, the introduction of High-Intensity Electromagnetic Filters proved ground-breaking in terms of removing…

Read MoreMagnetic Properties of Ceramic Minerals

Magnetic minerals and fine iron have plagued ceramic producers since the first glazed pot was produced many thousands of years ago. Early ceramicists adopted elaborate and colourful patterns to cover any imperfections caused by such contamination. Over time, the demand for white or single coloured ceramic products increased, making disguising any imperfection increasingly difficult. Ceramic…

Read MoreKeeping Ceramic Tiles Iron Free

When fine iron and iron-bearing minerals contaminate the raw material used to produce ceramic tiles, the consequences are costly. Such iron contamination causes visual and structural defects as well as affecting the surface finish in terms of brightness and whiteness. Tiles failing final quality checks are commonly returned for recycling. Those passing the initial quality…

Read More