Bunting Develops High-Intensity Electromagnetic Dry Filter

By Paul Fears | 24 February 2025

Bunting has developed a new Electromagnetic Dry Filter to remove free fine iron from powders. The high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.

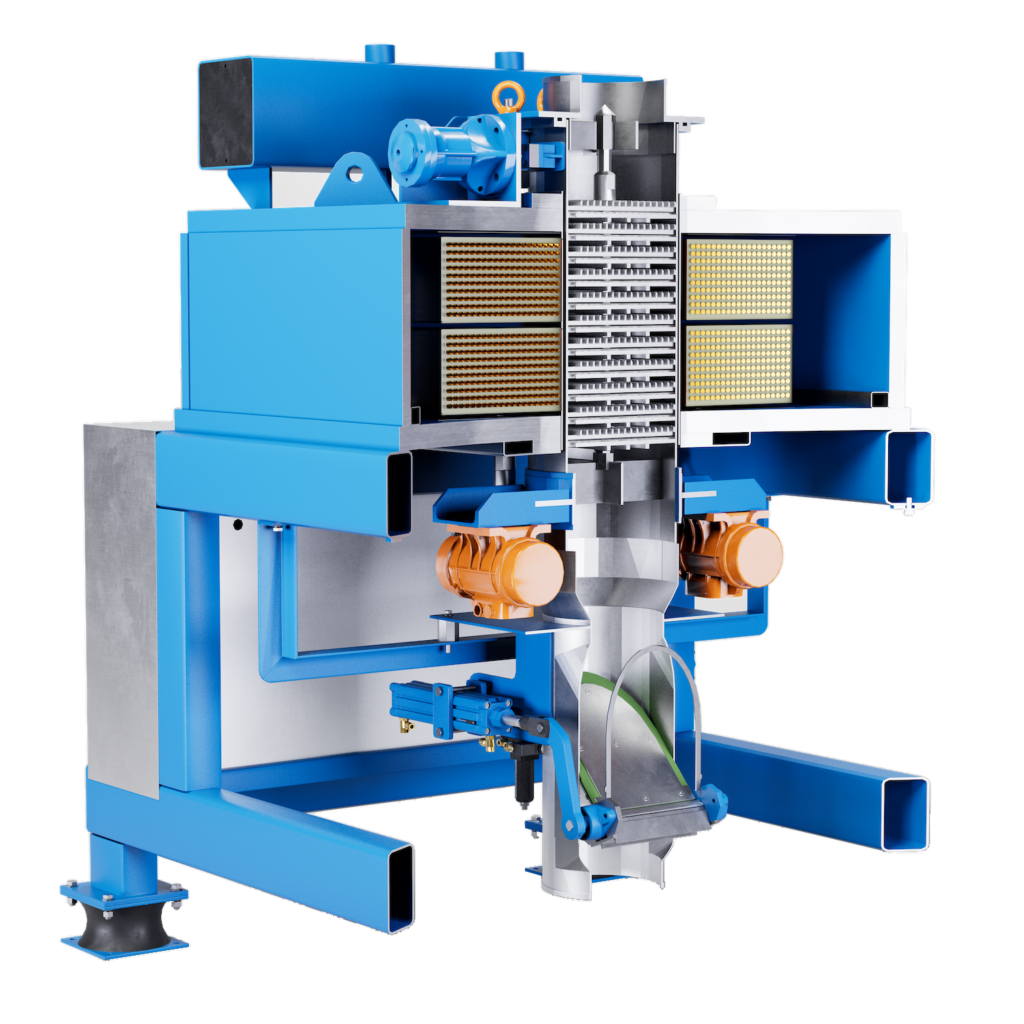

The Electromagnetic Dry Filter features a centrally-located vibrating canister inside a specially designed electromagnetic coil. The coil generates between 3,500 and 5,000 gauss in the canister, which is then concentrated on the points of the matrix to reach peaks of up to 12,000 gauss.

In operation, fine powder flows under gravity through the vibrating canister which is packed with magnetic stainless-steel matrix. Magnetic particles are attracted to the magnetically induced matrix and held until the batch feed is stopped. The electromagnet is then turned off, releasing the magnetic particles into a separate waste collection area, before processing is resumed.

The ultra-high magnetic fields and multiple magnetic capture points on the matrix enable enhanced separation of magnetically susceptible particles. The separation efficiency is far higher than permanent magnetic separators utilising permanent neodymium rare earth tube magnets. Many rare earth magnetic separators experience difficulties with bridging, ratholing and poor flowability due to particle size and shape, electrostatic charges, and environmental factors such as humidity.

The Electromagnetic Dry Filter is particularly suited for the magnetic particle purification of high-value fine powders, especially when processed and produced in controlled batches.

The process times and integration of the Electromagnetic Dry Filter into a production line is conducted through a separate control featuring a Siemens S7-1200 PLC and Human Machine Interface (HMI) control. To simplify maintenance and reduce production downtime, the Electromagnetic Dry Filter is fitted with a built-in jig crane to remove the centrally-located matrix canister for inspection or cleaning.

“The development of the Electromagnetic Dry Filter has been customer driven,” explained Adrian Coleman, Bunting’s Technical Director. “Processing powders is often challenging due to the way in which the materials behave. Our design engineers considered these challenges when designing the Electromagnetic Dry Filter, focusing on good powder flow, whilst maximising magnetic separation.”

The Electromagnetic Dry Filter expands the range of high-intensity magnetic separators Bunting supplies to the mineral processing, ceramics and powders sector, which includes the Electromagnetic Filter for purifying slurries and liquids.