Advanced Metal Separation at E-Waste World

By Paul Fears | 15 November 2021

The separation and recovery of fine and small metal is vital for the successful recycling of e-waste. On stand 314 at the E-Waste World Conference & Expo (30 November – 1 December 2021, Frankfurt Messe, Germany), Bunting is showcasing advanced metal separation technology specifically used in the recycling of electronics.

Metal Recovery from WEEE

Reclaiming metal from e-waste is inherently challenging with a wide size-range of metal particles and metal liberation difficulties. A typical e-waste recycling process will include several stages of metal separation, starting with the primary removal of ferrous metals using Overband Magnets and Pulley Magnets.

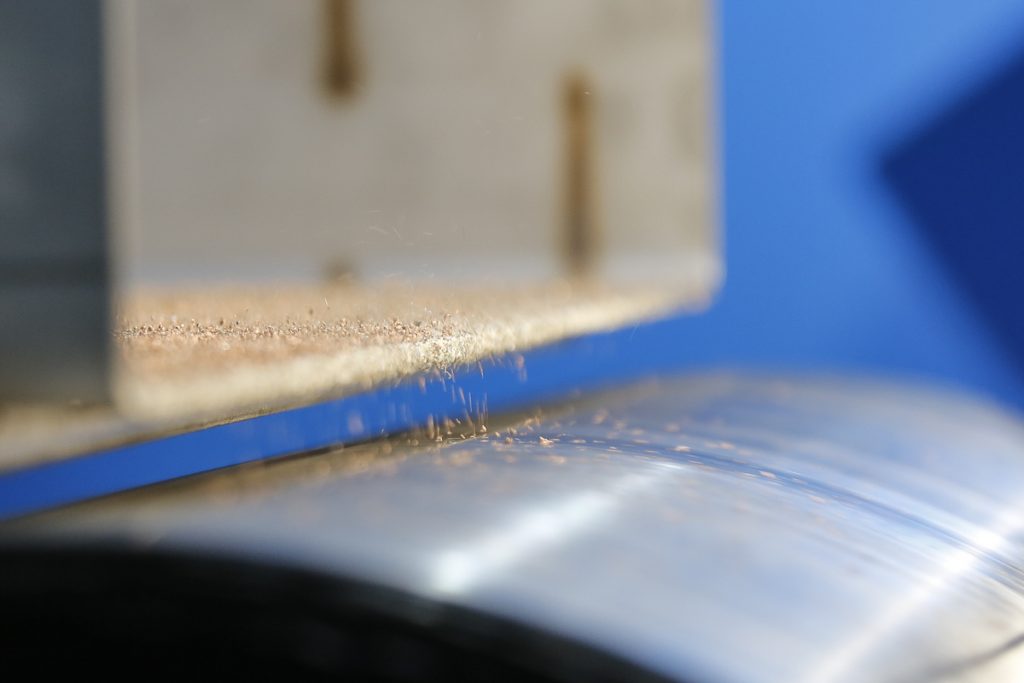

The ferrous metal-free fraction passes onto an Eddy Current Separator to separate non-ferrous metals such as aluminium. The particle size range of the feed dictates the specific model of Eddy Current Separator. The model HIC (high-intensity concentric) produces an ideal separation of particles above 12mm, with the HIE (high-intensity eccentric) achieving optimum recovery of particles below 12mm.

The Stainless Steel Separator (models SSSC and HISC) follows the Eddy Current Separator and uses ultra-high strength magnetic forces to separate weakly magnetic fragmented or shredded stainless steel. The separation technology also enables the separation of printed circuit boards (PCBs), with the strong magnetic field producing enough attraction on small ferrous screws and other attachments to enable recovery. A tabletop demonstration model of the SSSC will demonstrate separation capabilities on the Bunting stand at E-Waste World.

Also on display at E-Waste World is the ElectroStatic Separator, located at the final separation stage for the <12mm fraction. The earlier-positioned Eddy Current Separator recovers non-ferrous metals down to nominally 2mm, leaving fine copper wire and other fine metals. These metals are recovered using electrostatics. Screening at around 3mm provides the optimum particle size for electrostatic separation. ElectroStatic separation occurs by inducing an electrostatic charge into a conductive dry-liberated particle.

This combination of advanced metal separation technology enables the recovery of the majority of ferrous and non-ferrous metals. On Bunting’s are experienced applications engineers along with regional agent Marcel Graef of 3SMI.

Related Recycling Articles

For further information on Magnetic Separators, Eddy Current Separators, and ElectroStatic Separators for metal recovery in recycling applications or to discuss a specific project including undertaking tests in our Customer Experience Centre, please contact our technical sales team on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Photographs taken by Paul Fears Photography

Follow us on social media