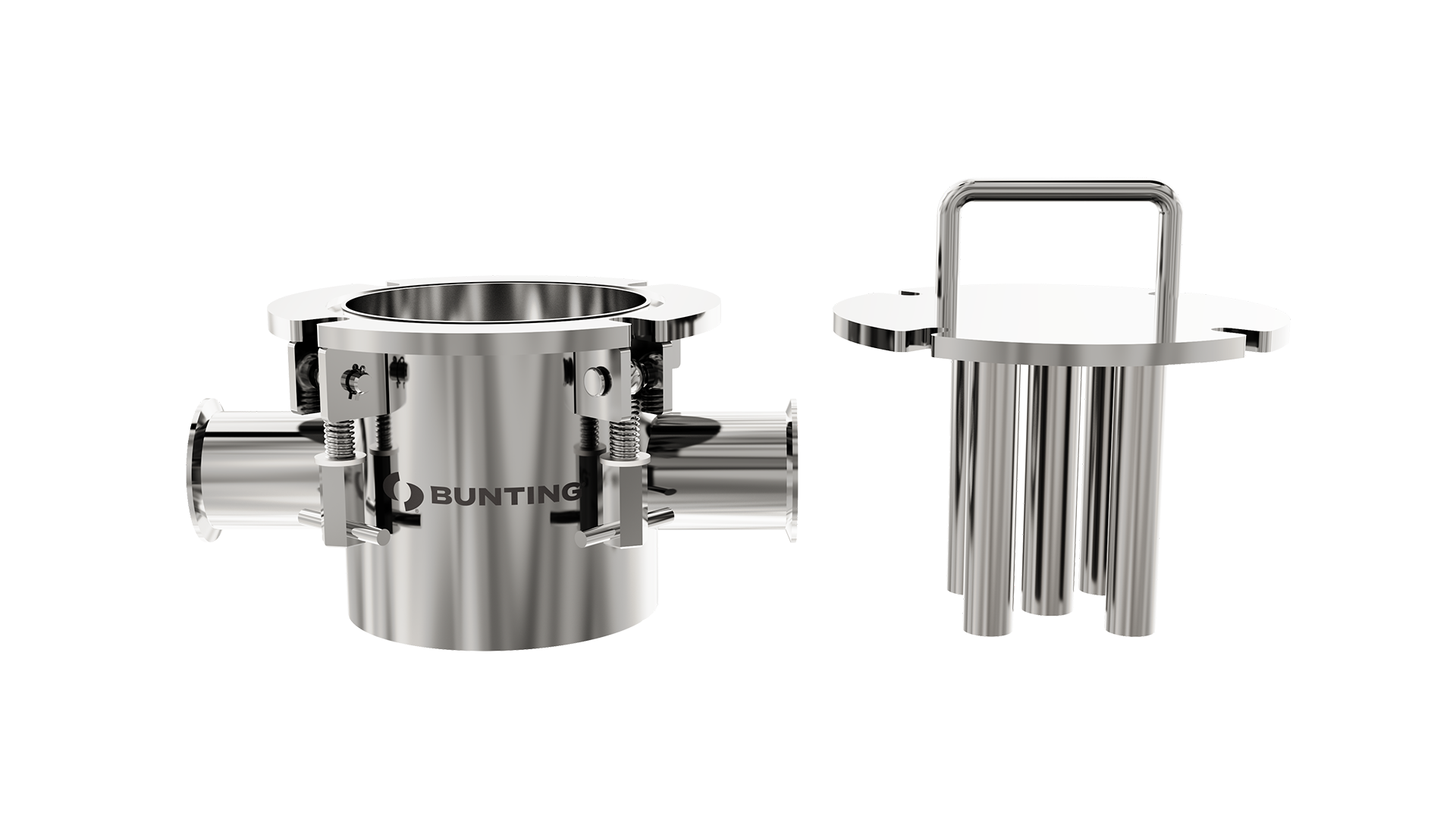

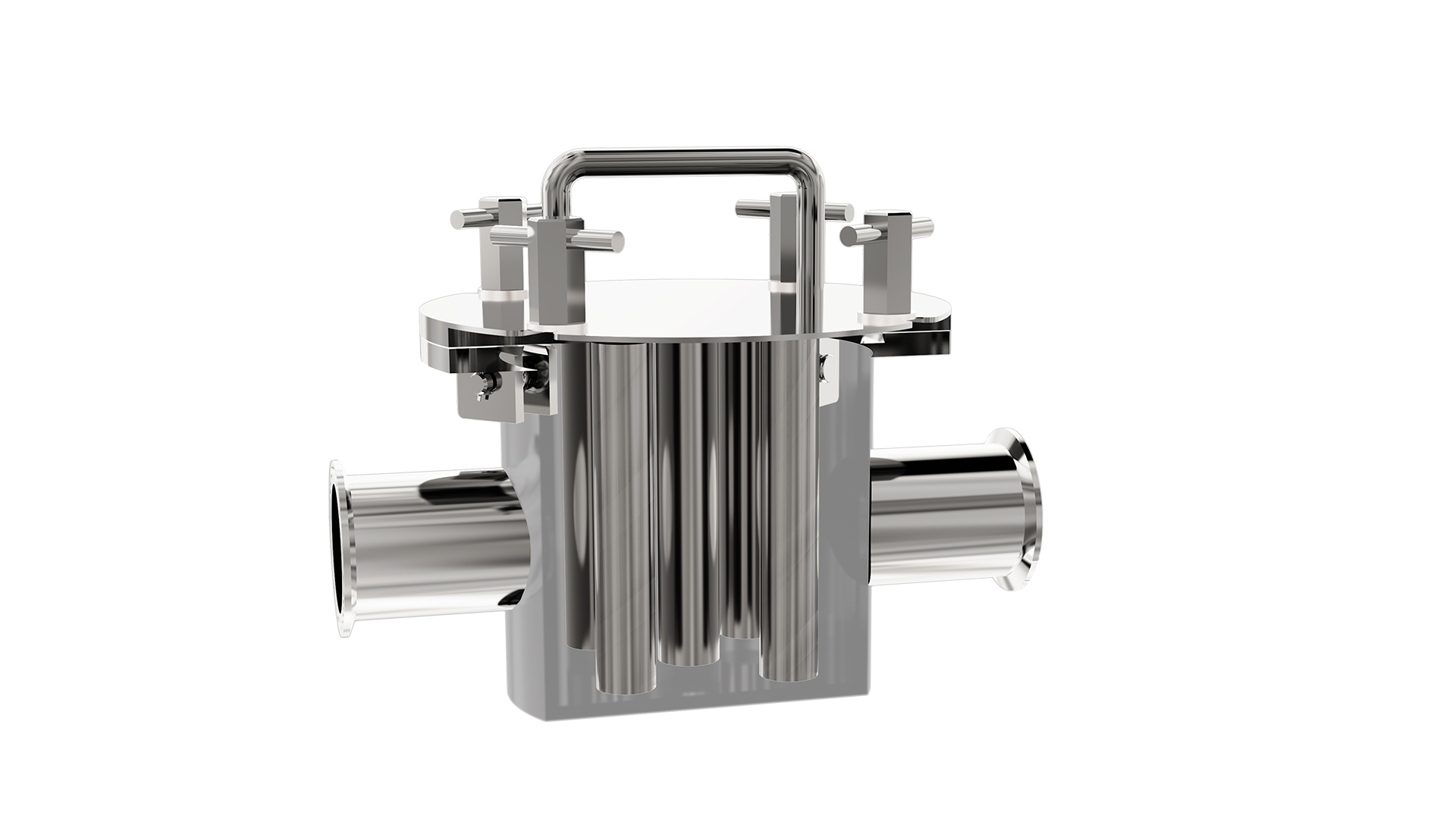

Liquid Magnetic Separator

| INDUSTRIES | Food, Pharmaceutical, Ceramic |

| MAGNET | Neodymium |

| STRENGTH | 10,000 Gauss & 6 kgs of pull |

| PRODUCT | Liquids, Pastes, Slurries |

| MATERIAL | Stainless Steel |

| LINE SIZES | 50mm, 80mm, 100mm (2", 3", 4") |

| PRESSURE | 145 psi (10 bars) |

| TEMPERATURE | 120°c (248°F) |

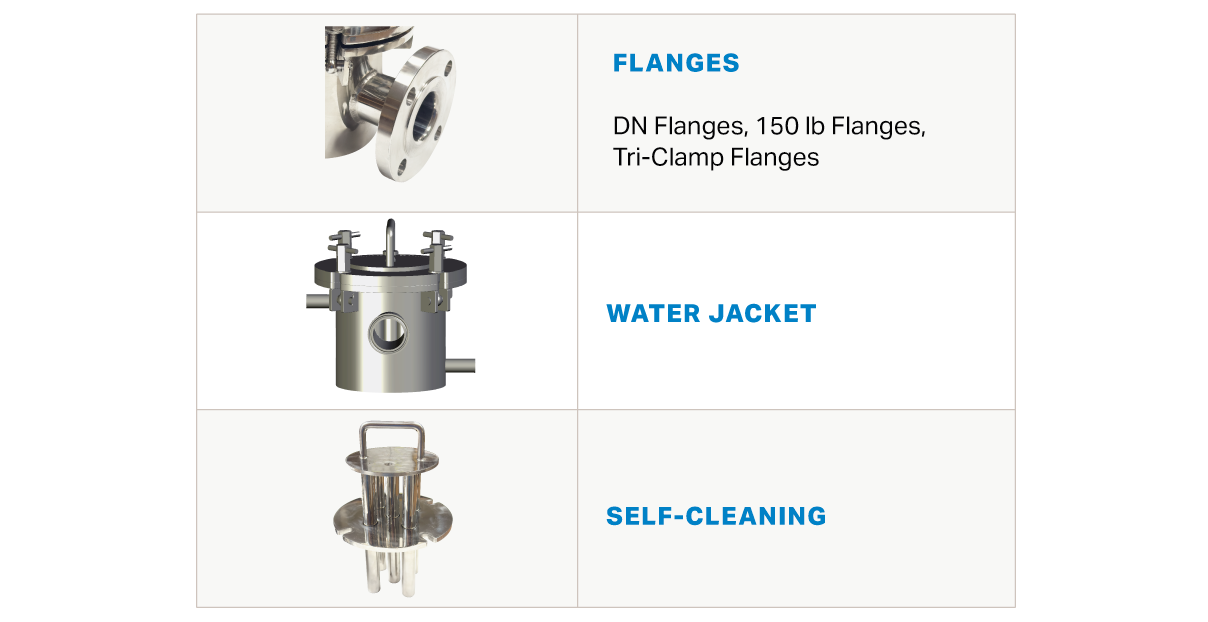

| OPTIONS | 70 kg flanges, water jacket, self-cleaning |

BENEFITS/OPTIONS

ABOUT

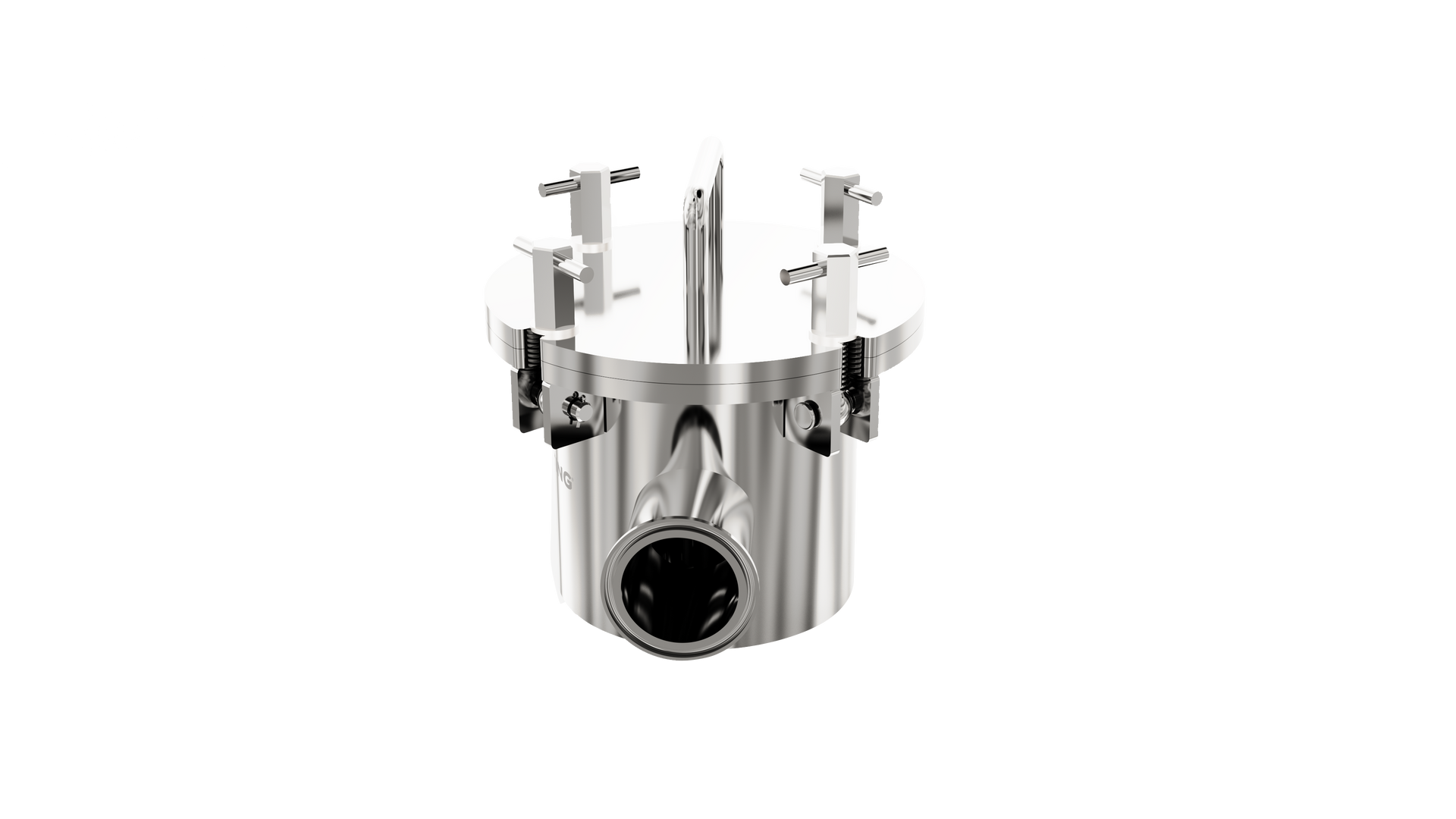

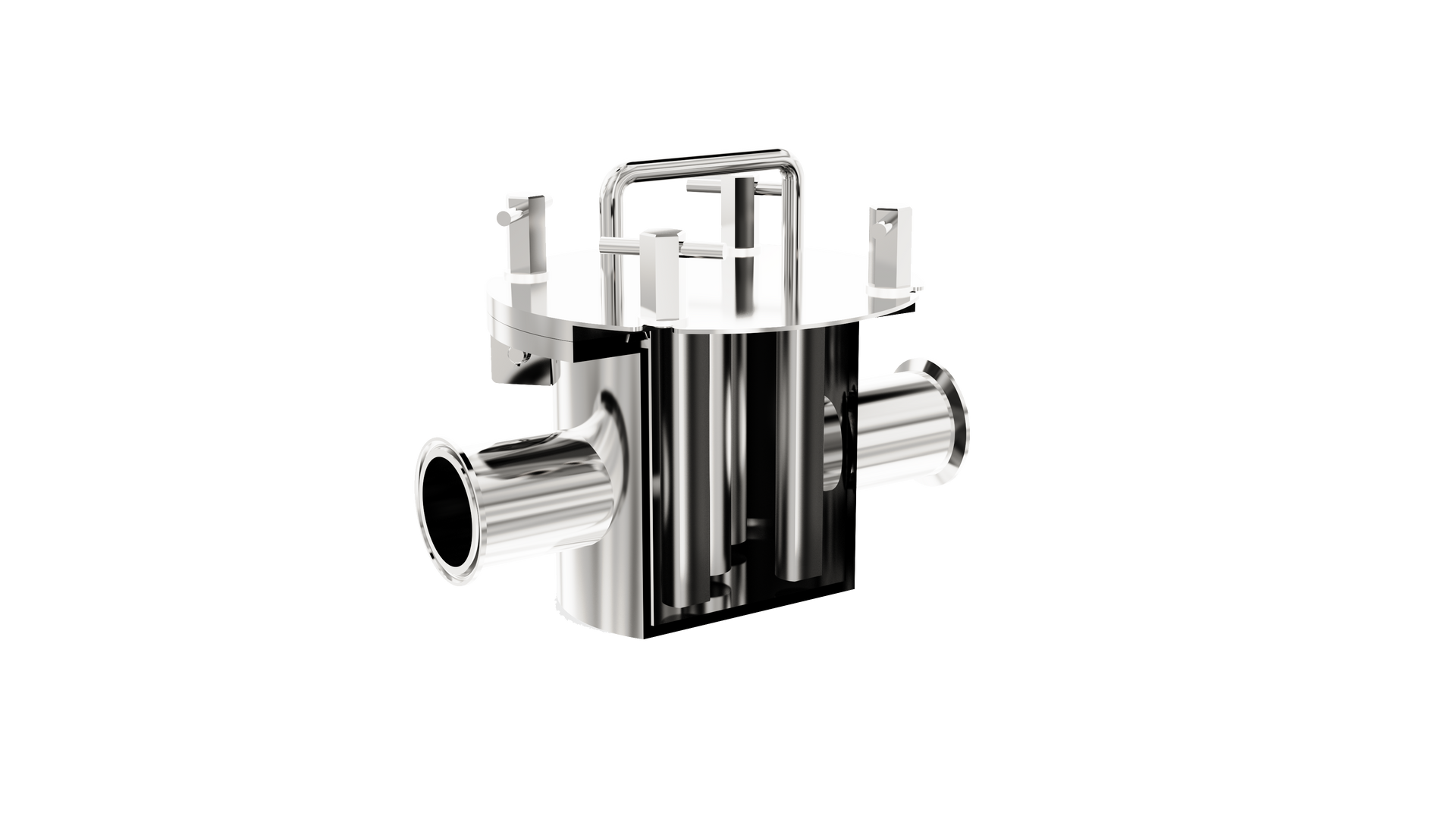

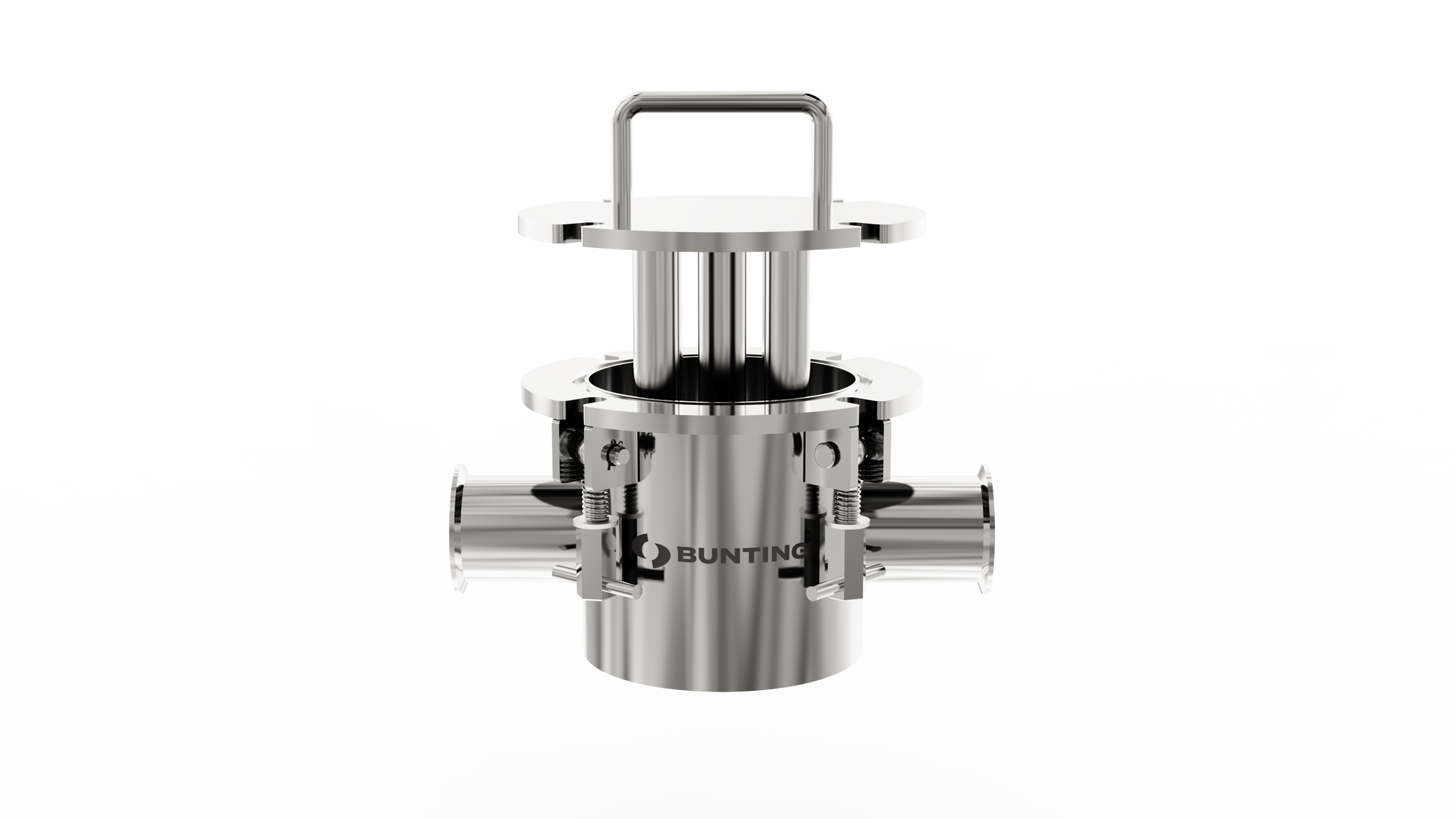

Bunting’s Liquid Magnetic Separators are advanced devices that extract ferrous contaminants from various liquids, including dairy goods, fruit drinks, oils, and soups. These devices employ neodymium magnets, generating a 10,000 gauss magnetic field to capture both large and fine ferrous particles.

The separators’ exceptional magnetic strength allows them to remove obvious metal contaminants and tiny particles, including traces of work-hardened stainless steel. This capability ensures product purity, which is vital in food, medicine, and ceramic production.

Made from 316 stainless steel, these separators meet food-grade standards, making them suitable for sensitive manufacturing settings. Their design accommodates different liquids, from acidic juices to thick oils and chunky soups, catering to various industrial needs.

Features like easy maintenance, energy efficiency, and optional full automation make Bunting’s Liquid Magnetic Separators a comprehensive solution for firms aiming to improve product quality and meet safety requirements. Controlled tests on smaller laboratory filters are available to ensure the separators meet specific application needs.