Pneumatic Inline Magnets for Animal Feed

By Paul Fears | 15 July 2024

Bunting’s Technical Sales Engineer, Peter Buckley, recently visited the site of an animal feed producer to review installed Pneumatic Inline Magnets and assess a new requirement. The four (4) Pneumatic Inline Magnets (PIMs) operating successfully at the animal feed plant were installed in phases between November 2020 and September 2023.

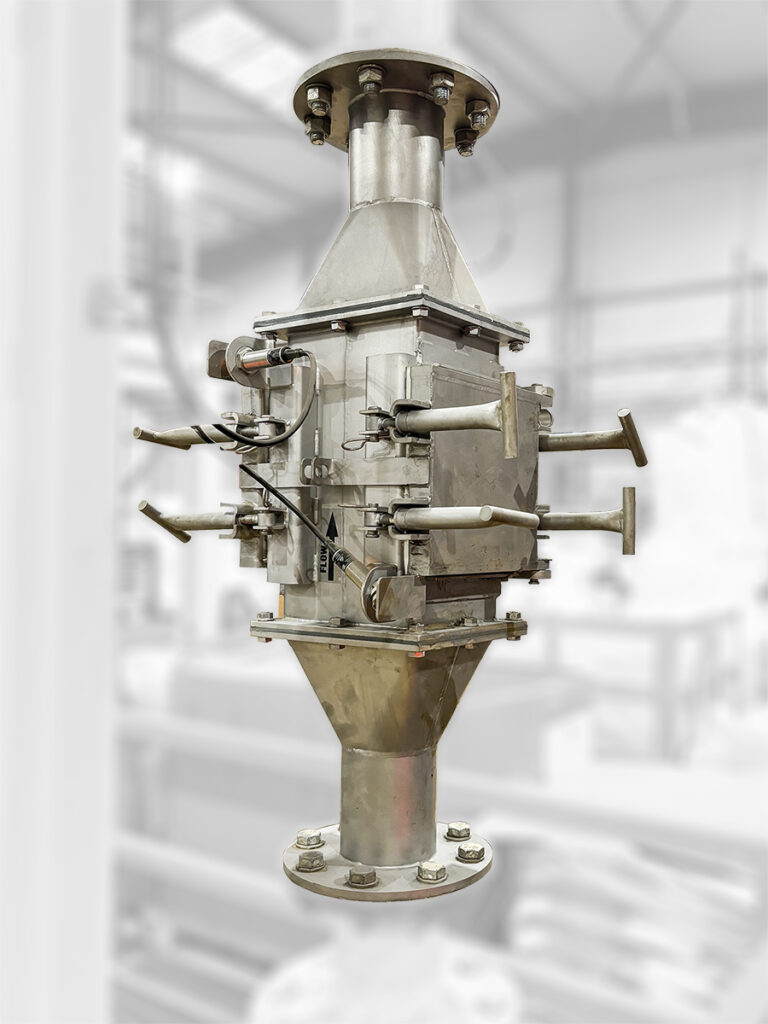

Inline Magnets are versatile and cost-effective magnetic separators that connect into both gravity-fed and pneumatic pipelines. With a plate magnet fitted on one or both sides of the body, the Inline Magnets are ideal for removing occasional tramp ferrous metal from materials transported in pipelines. Constructed from stainless-steel, with food-grade sanitary options, the pneumatic designs are ATEX rated.

Pneumatic Inline Magnets

The installed Pneumatic Inline Magnets sit in 4” (101mm) and 5” (127mm) diameter pipelines. In operation, animal feed is pneumatically fed up through the centre of the housing and between two high-strength neodymium plate magnets. Tramp ferrous metal and any other magnetically-susceptible particles, including fine iron, are attracted to the surface of the plate magnets and securely held. A scheduled maintenance programme includes the regular manual cleaning of the plate magnets, removing any captured magnetics.

Pneumatic Inline Magnets (PIMs) are designed for installation in pneumatic conveying systems with a pressure rating up to 15psi. Each plate magnet has a magnetic field enhancing tapered step, which traps captured ferrous material behind a lip and out of the product flow. The plate magnets are fixed in place with four thick threaded bolts mounted on each corner. An extended ‘T’ section fits onto the bolt head for easy tightening and loosening. The compression of a food-grade gasket, fitted between the plate magnet and the housing, ensures the system is adequately sealed and suitable for operation on a pneumatic conveying line. PIMs are ideally suited for removing tramp metal from dry-free flowing materials such as animal feed.

“The production and maintenance team are always surprised by the amount of magnetic tramp metal captured by the PIMs,” explained Peter. “Removing the metal not only ensures that the end-product is metal-free, but also prevents damage to other processing equipment. The additional PIM is for a new line as the level of production increases.”