Electro Magnetic Filter for European Ceramics Producer

By Paul Fears | 28 November 2022

A leading German ceramic manufacturer is cleaning ceramic glaze with a high-intensity Electro Magnetic Filter designed and manufactured by Bunting. The successful removal of fine magnetics reduces finished product rejects and increases surface brightness.

High-Intensity Electro Magnetic Filters

The Electro Magnetic Filter provides one of the most effective methods of removing problematic fine iron and paramagnetic minerals from ceramic slips and glazes. The separation efficiency of the technology is significantly better than permanent magnetic separators such as Liquid Pipeline Separators and Tube Magnet configurations.

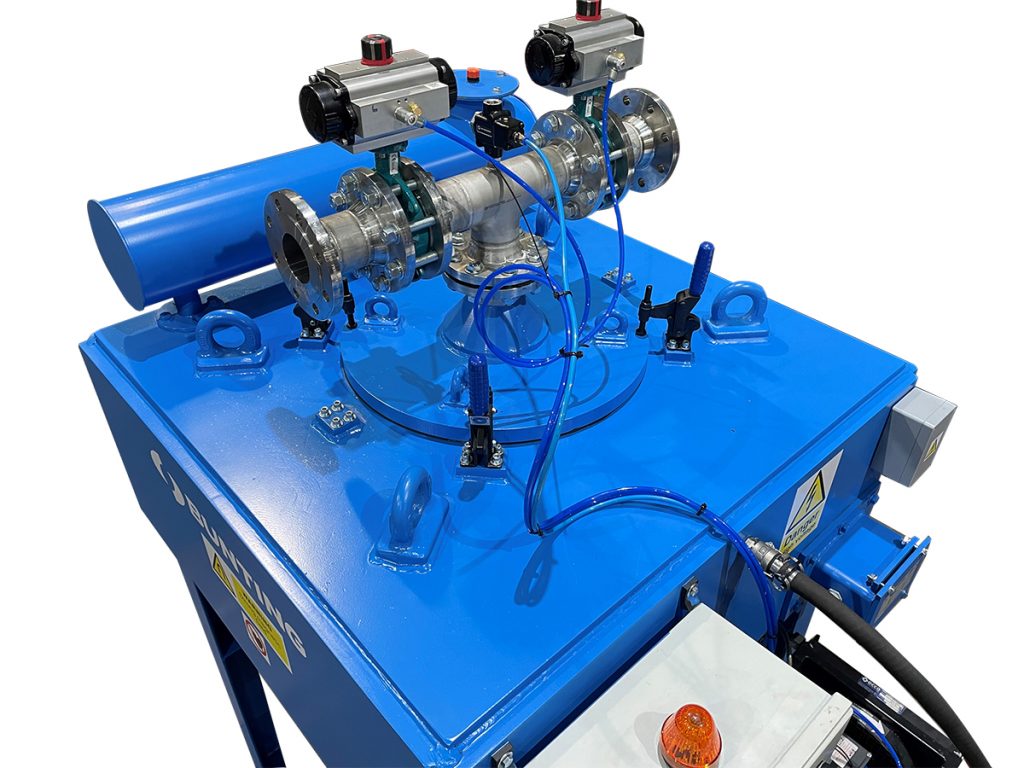

Electro Magnetic Filters consist of an electromagnetic coil positioned around a central hollow core containing a magnetic (400 series) stainless-steel matrix of various designs. The highly efficient computer designed coil generates a high intensity magnetic field that intensifies on the points of the matrix creating the magnetic force needed to separate paramagnetic particles from the slurry.

The rectangular steel casing enclosing the magnetic coil intensifies the magnetic field into the hollow centre of the coil. Valves, mounted on the top and bottom of the Electro Magnetic Filter, close and open in a controlled timed sequence for product feed and discharge, as well as matrix cleaning using water and air.

In operation, ceramic glaze or slip feeds up through central canister packed with magnetic stainless-steel matrix. The magnetic field of the Electro Magnetic Filter intensifies on the sharp points of the matrix, enabling the capture of fine magnetic particles such as free iron and magnetic minerals.

Project Details

This ceramics project in Germany required a large model HIF225-50 Electro Magnetic Filter, which generates a background magnetic field of approximately 6,500 gauss inside the central canister. The points of the matrix enhance the background magnetic field by up to four-times, with the 6,500 gauss models generating peak fields above 2-Tesla.

The model HIF225-50 stands 2015mm high, 1590mm deep, and 1140mm wide and weights approximately 4.6 tonnes.

In Operation

The ceramic glaze feeds up through the Electro Magnetic Filter for a period of approximately 60 minutes. On an automatic operation cycle, managed by a separate control panel, the valves system then stops the feed, diverting the glaze back into the feed tank, whilst the system goes through a cleaning cycle. This involves discharging the captured magnetics from the canister and cleaning of the matrix, which lasts for approximately two-minutes. The control enables adjustment of the sequence times to suit the processing of a wide variety of ceramic glazes. In this project, the HIF225-50 handles between 3-4 tonnes per hour of glaze with 64% solids.

“If fine iron and magnetic minerals are not removed from ceramic glaze they cause surface defects and discolouration,” explained Phil Tree, Bunting’s European Sales Manager. “In this project, we are working with one of the world’s leading ceramics manufacturers. They understand the necessity and benefits of automatically removing all magnetics, which is only possible with an Electro Magnetic Filter.”

Related Technical Articles

- Keeping Ceramic Tableware Iron Blemish Free

- Keeping Ceramic Sanitaryware Iron Free

- Keeping Ceramic Tiles Iron Free

Optimum Magnetic Separation Reduces Rejects

Understanding the ceramic manufacturing process is important when making recommendations for the optimum magnetic separation equipment. However, each manufacturing process is unique and a visit by a local Bunting Sales Engineer will help understand a specific process and iron contamination issue and propose a specific solution.

For additional information on eradicating iron contamination in ceramic tableware, tiles, sanitaryware, or technical ceramics, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media