quickTRON 07 RH

The high-sensitivity quickTRON 07 RH Metal Detector precisely detects tramp metal in free-falling bulk materials where there are stringent hygiene requirements. This metal detector prevents damage to processing equipment as well as ensuring metal-free finished product quality in accordance with ISO9000 and HACCP. Used widely in the food, pharmaceutical, and chemical industries, the quickTRON 07 RH detects and automatically rejects small ferrous, non-ferrous, and stainless-steel metal contamination. ATEX conforming versions available.

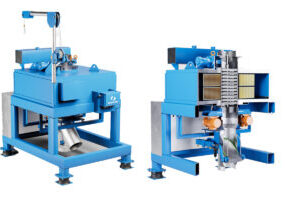

Description

The quickTRON 07 RH Metal Detector automatically and continuously detects entrapped and free tramp ferrous, stainless-steel and non-ferrous metals. Designed specifically for free-flowing, gravity-fed applications where there are stringent hygiene requirements, the quickTRON 07 RH is compact and easy to install in new and existing installations.

The hygienic open-frame and round reject gate design ensures there is no accumulation of inaccessible dirt. The quick-out reject gate can be removed and separated from the rest of the unit for cleaning in a few easy steps.

The quickTRON 07 RH features a ‘power line’ detector coil with layered interference shield meaning that a plastic sensor pipe is not required. The welded pipe connections of the detection coil ensure no external exposure, stopping external interferences reaching the internal sensing field.

There is design flexibility to suit a wide range of installations. The quickTRON 07 RH has an integrated electronics cabinet.

The pneumatic actuated reject gate is rugged, reliable and fast reacting.

The extended system monitoring guarantees maximum reliability. Aside from the major electronic components there is continuous monitoring of the air supply and reject gate, with any type of fault reported in real time

Operation

The quickTRON 07 RH series electronic metal separator automatically detects and rejects metallic contaminants from freefalling materials without interrupting production. Clean product passes freely through the metal separator. A metal contaminant in the product stream alters the high frequency field generated by the detection coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and the double actuating air cylinder that operate the reject flap. The contaminant is instantly diverted from the good product stream assuring minimal good product loss.

The reject time is adjustable. In the case of several metal particles being present, the reject time will be extended accordingly, to assure a metal free product. Once the metal has been ejected, the reject flap returns automatically to its normal position.

Typical tramp metal detected includes:

- Washers

- Nails

- Screws

- Nuts and bolts

- Wire

- Swarf

- Broken screens

- Foil

- Metal from shredder and granulator blades

Applications

The quickTRON 07 RH Metal Detector provides vital protection of processing plant and is commonly mounted prior to mills, mixers, kneaders, extruders and other delicate processing equipment, as well as prior to final stage packing.