Drum Magnets – Permanent

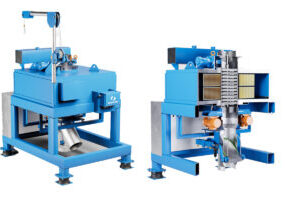

The permanent Drum Magnet is a versatile and robust magnetic separator, perfectly suited to recover para and ferro magnetic materials from dry granular.

The permanent Drum Magnet comes in a wide range of widths, drum diameters and magnetic strengths. The strength of the magnetic system results from a causal connection of its design (axial or radial) and the magnetic element used (standard ferrite or high-intensity rare earth ). The Drum Magnet enables high capacity processing with limited maintenance.

Description

A permanent Drum Magnet has a stationary 180-degree arc shaped magnetic system positioned inside a non-magnetic, commonly stainless steel, shell. The shell rotates around the magnetic system at a speed determined by the volume of processed material. Each individual magnet of the magnetic system is mounted onto heavy-duty back plates, to maximise the projection of the magnetic strength into the product stream. This enhances the Drum Magnet’s performance and also reduces any leakage of magnetic field into the shaft and bearings, subsequently extending their service life.

The magnetic system is constructed to produce either a radial or axial magnetic field to suit the application.

Permanent Drum Magnets are available in a wide range of sizes in terms of diameter and width. Commonly, Drum Magnets with a 300mm diameter shell are suitable for materials with a small particle size range, whereas larger diameters are suitable for larger bulkier materials (e.g. as found in recycling).

The permanent magnet system is constructed using either fully stabilised ferrite magnets or the highest grade of rare earth neodymium magnets. The wire wrapped model, featuring rare earth neodymium magnets, produces a boosted magnetic field to enable the separation of para magnetics (e.g. minerals, recycled materials)

In the recycling sector, Permanent Drum Magnets work prior to the Eddy Current Separator as part of a Metal Separation Module. The Drum Magnet extracts small ferrous metals and consequently presents a non-magnetic fraction to the Eddy Current Separator for recovery of non-ferrous metals. The required strength of the Drum Magnet is dependent on the application.

Related Blogs

Operation

Dry materials are fed onto the top of the Drum Magnet, ideally from a vibratory feeder for an even spread and steady feed. Magnetically susceptible materials are attracted to the magnetic field of the stationary internal magnetic system and held to the rotating shell surface of the Drum Magnet. The revolving shell transports the magnetic particles out of the magnetic field where they are discharged into a collection area or onto a receiving conveyor. Non-magnetic material is unaffected and flows under a normal trajectory.

An adjustable splitter enables a highly precise separation of the two fractions.

The strength of the magnetic element (either standard strength ferrite or high-strength rare earth neodymium) is selected on the basis of the magnetic susceptibility of the material. There are two designs of magnetic system to suit specific separation objectives:

- Axial – where the polarity runs along the width of the Drum Magnet. This is ideally suited for ferrous material recovery with an objective of maximising its purity and limiting the carry-over of non-metallics into the magnetics. The axial field flips attracted magnetics as they move from one pole to another, freeing entrapped non-magnetics

- Radial – such designs feature poles running vertically down the Drum Magnet. This design enables the highest level of recovery, especially of weakly magnetic materials. Once the magnetic particle moves and is held on one of the vertical poles, it remains on the pole and securely held until leaving the magnetic field underneath the drum

Models

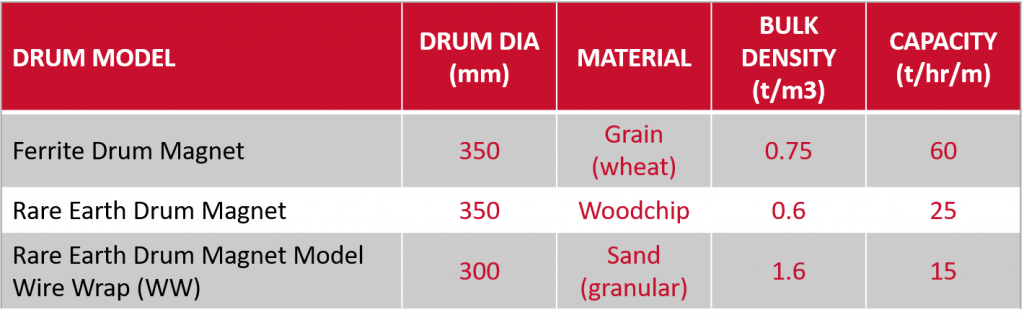

Drums Magnets are available in three magnetic strengths:

- Ferrite Drum Magnet (standard strength) – Ideally suited for separating larger ferrous tramp metal and strongly magnetic particles;

- Rare Earth Drum Magnets (high-intensity) – for the separation of fine ferrous particles and weakly magnetic materials;

- Wire Wrapped Rare Earth Drum Magnets (extreme-intensity) – for the separation of para magnetic materials specifically for mineral processing and foundry applications;

Standard Drum Magnet diameters range from 300mm to 600mm in 50mm increments. Bunting provides bespoke designs and has supplied Drum Magnets with diameters from 200mm up to 900mm.

Drum Housings

Drum Magnets are supplied as bare drum (for incorporation into a customer’s machine or process) or in a completely enclosed housing. The enclosed housing option is recommended to retain contaminations (e.g. dust).

Housings are manufactured in robust mild steel or stainless steel. Inspection covers, aspirators and splitters/divert plates are provided as standard. Bunting engineers commonly work with customers to design a bespoke housing to suit a specific installation.

Applications

The permanent Drum Magnet is perfectly designed to remove ferrous and weakly magnetic particles from dry non-metallic minerals. Specific applications include:

- Mineral Processing

- Feldspar

- Silica Sand

- Garnet

- Abrasive and refractory minerals including Corundum

- Beach Sands (ilmenite, etc)

- Fine iron ores

- Ceramics

- Removing free fine iron from spray dried ceramics;

- Recycling

- Cullet (crushed glass)

- Metal recycling plants

- Granulated steel slag

- Granulated plastic waste

- Recovering ferrous metal from incineration ash

- Foundries

- Separating and recovering ferro and para magnetic particles from reclaimed foundry sand

- Recovering Chromite

- Plastics

- Removing ferrous metals from plastic beads

- Food Processing

- Grain

- Granular materials

Videos