Gravity Free Fall Metal Detectors

Metal Detectors for Gravity Free Fall Applications

Gravity free fall metal detectors and separators are designed specifically to isolate and separate any contaminated material moving in the product flow. They do this as the metal detector automatically picks up all kinds of metals, both ferrous and non-ferrous from the product flow and it is all conducted without any interruption to the line process.

Metal separator for the inspection of granules and flakes in free fall.

- Detects and separates all metals

- Outstanding Price/performance ratio

- Ideal standard solution for regrind quality assurance and machine protection

- Compact metal detector and easy to integrate

Metal separator for the examination of bulk materials in free fall.

- Detects and separates all metals encapsulated or as loose parts.

- Extremely precise metal detector – impressively reliable.

- Durable and solid – a profitable investment.

- ATEX conforming versions available.

- Compact, easily integrated.

Metal separator for the examination of free falling bulk materials, fulfilling even most stringent hygiene requirements.

- Detects all metals encapsulated or as loose parts.

- Extremely precise metal detection - impressively reliable

- Immune against outside interference.

- Easy to clean - fulfils the highest hygienic demands.

- Compact, easily integrated.

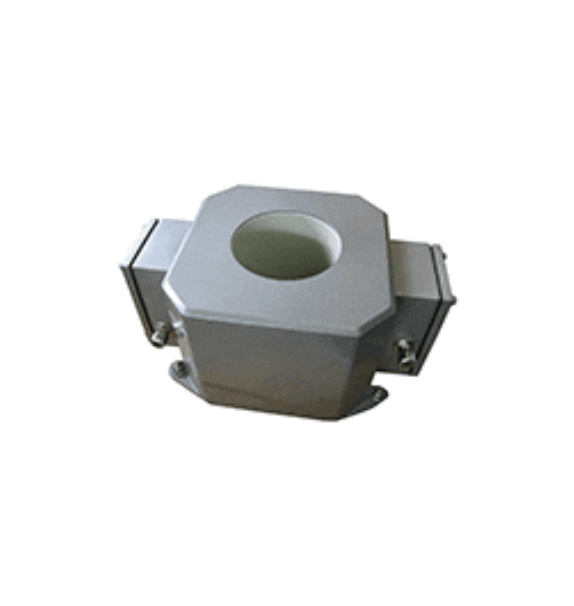

meTRON 05 PowerLine

Metal detector with round aperture for the installation in bulk conveying lines.

- Detects all metals encapsulated or as loose parts

- Immune against electromagnetic interference

- Impressive simple operation

- Installation without additional sensing tube

- Variable and flexible due to tailor-made system concept

meTRON 05 CR

Metal detector with round aperture for the installation in pipes.

- Detects all metals encapsulated or as loose parts.

- Highest sensitivity even in rough industrial environments.

- User friendly and reliable technology, proven for many years.

- Used for quality control or machine protection.

- Specifically tailored system solutions with sensing tubes and support frames.

meTRON 07 FlatLine

Slim metal detector for mounting between multihead weighers and vertical bag fillers.

- Detects all metals in solid products or as loose parts.

- Minimum installation height for maximum integration ease due to unique technology.

- The new performance benchmark! Highest standard of detection accuracy with ultimate operational safety.

- Revolutionary simple operation.

- Compliant with quality surveillance rules according to HACCP, IFS, BRC, SQF.

- Variable and flexible due to tailor-made system concept.

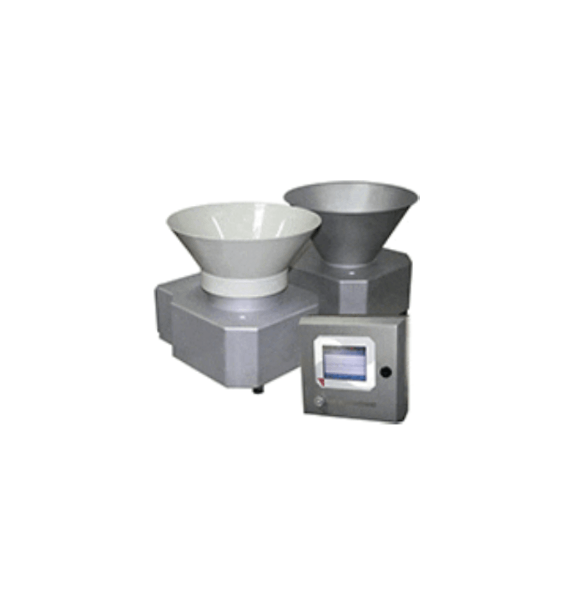

PharmaTRON 07 HQ

Metal separator for the pharmaceutical industry for the inspection of tablets and capsules

- Detects and separates all metals encapsulated or as loose parts.

- Meets the highest hygiene requirements.

- Fast decontamination of all product touching parts without tools.

- Fits every tablet press and deduster installation.

- High throughput owing to round equipment design DN50.

Bunting's Gravity Free Fall Metal Detector Range

Bunting offers a comprehensive range of gravity free fall metal detectors, designed specifically to meet the requirements and demands of the manufacturing and processing industries. They're designed to automatically identify ferrous metals, non-ferrous metals, and stainless steel within the product flow and eject them whilst minimising product loss.

Downtime can be costly for business, so our gravity free fall metal detectors are designed to operate without process interruptions so that your operations are efficient and reliable. The high level of purity in your product allows you to protect your brand reputation, prevent costly product recalls, and provide your customers with a great end product.

How do Gravity Free Fall Metal Detectors work?

Gravity free fall metal detectors are primarily found in the food industry, removing contaminate metal from product or ingredient streams such as flour, grain, nuts and sugar. When these products are processed, they fall through the detectors with any contaminate metal being identified and removed.

Avoiding Machinery Downtime

Aside from ensuring product quality Bunting's gravity free fall metal detectors also safeguard machinery. If contaminate metal makes its way into your production line it can cause significant damage to equipment such as injection moulders, extruders, nozzles, grinders, and mixers. If process machinery is damaged it can be quite costly to repair, both financially and operationally due to downtime.

Gravity Free Fall Metal Detector Installation

Gravity free fall conveyors can be utilised in various different stages throughout the production process. They can be used to inspect incoming goods, where they play a crucial role in detecting metal contaminates that may have slipped past suppliers. This is especially important for the food industry, where metal could contaminate raw ingredients like wheat or vegetables leading to damage to mixers or mincers which could completely halt production. Additionally, gravity free fall metal detectors can be used as a final check for outgoing goods, the HACCP framework suggests that a final check should be performed on goods if recontamination can't be completely ruled out.