51 Metal Contaminated Food Products Recalls

By Paul Fears | 06 November 2023

In August 2023, the UK’s Food Standards Agency reported the recalling of 51 separate food products due to concerns about metal contamination. The food product recalls affected some of the UK’s largest supermarkets, including Tesco, Sainsbury’s, Asda and Aldi.

In each case, the Food Standards Agency’s risk statements reports that ‘these products may contain pieces of metal [and plastic] which may make them unsafe to eat’.

The Metal Contaminated Products

The metal contaminated foods mainly include pastries and ready meals. UK supermarket giant Tesco recalled four (4) various pastry products including Cheese & Onion Rolls. The Compleat Food Group, which supplies major UK supermarkets including Asda, Sainsbury’s, and Aldi, recalled 20 different chilled pastry products. These included Chicken Tikka Slices, Sausage Rolls, and various pies. High quality food producer Avoca recalled 27 different products including vegetable lasagne, sweet & sticky BBQ sauce, and various soups.

Source of Metal Contamination

The number of food product recalls due to metal contamination reported in August 2023 is unusually high. The 51 product recalls relate to three (3) separate food alerts. However, even that is high when compared to a total of ten (10) metal-in-food alerts reported in 2022 and five (5) in 2021.

Metal contamination of food occurs during the manufacturing process. Wear and failure of processing equipment, such as pumps and screens, can introduce rogue items of metal into the process. Without effective metal removal and detection equipment in place, the metal contaminated product will reach the consumer.

Removing and Detecting Metal Contamination

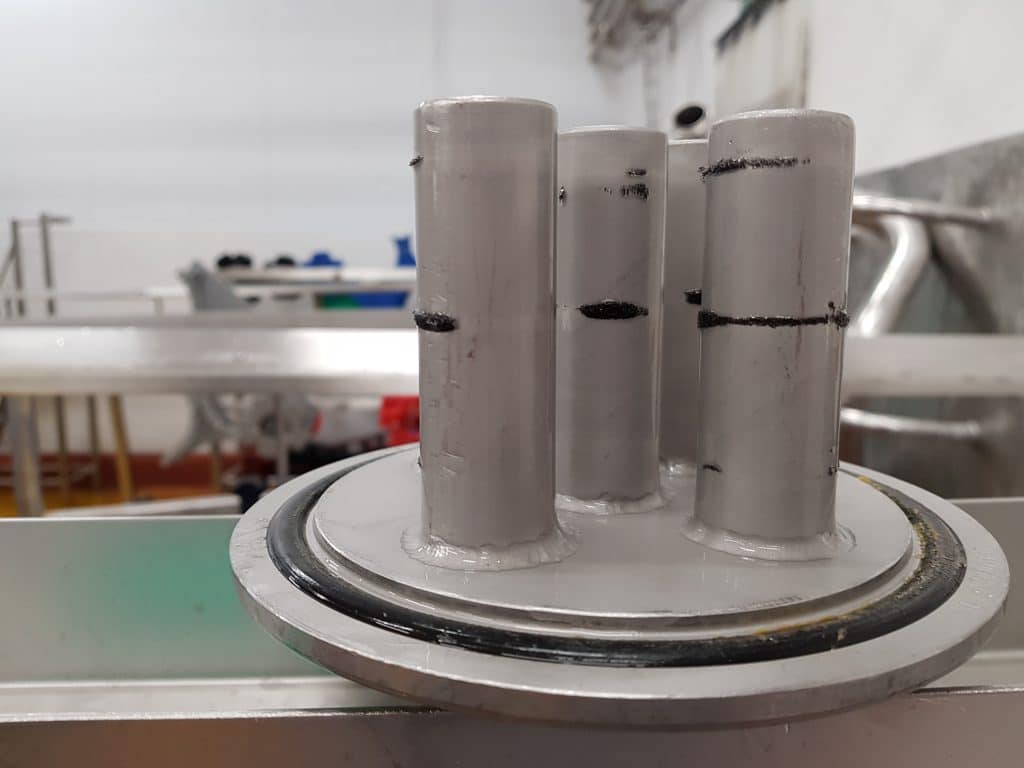

Most food processing plants feature systems to remove and identify metal contamination prior to the product leaving the premises. During the manufacturing process, magnetic separators attract and securely hold any ferrous metal or magnetically susceptible plastic contamination. To maximise metal capture, most of the magnetic separators use ultra-strong rare earth magnets (neodymium or samarium cobalt).

The most commonly used designs of magnetic separators include:

- Liquid Pipeline Magnets

- Tube and Grid Magnets

- Plate Magnets

- Inline Magnets

- Bullet Magnets

- Drawer Filter Magnets

Although metal detectors feature in the food manufacturing process, they are commonly located prior to and after packing. The high-sensitivity free-fall and tunnel-type metal detectors locate even the smallest ferrous or non-ferrous metal shard hidden in a food product and include:

- meTRON 07CI (tunnel-type for mounted around a conveyor)

- quickTRON 05A (free-fall and installed in the process and prior to packing)

- quickTRON 07 RH (free-fall and installed in the process and prior to packing)

Regular Auditing

Both the magnetic separators and metal detectors require regular auditing to confirm the performance meets the production requirements. Changes in the process, suppliers, and ingredients can all affect the performance and allow the metal to pass through into the final product.

Bunting engineers regularly conduct in-depth audits, physically checking the magnetic integrity of the magnetic separators and the sensitivity of the metal detectors. Following the onsite audit, a report is produced and forms part of any company’s ongoing process quality improvement plan.

Related Metal-in-Food Technical Articles

For further information on Metal Detectors and Magnetic Separators used to find and remove metal contamination in any food processing application, please visit our website or contact us on:

Email: Michael Allen at mallen@buntingmagnetics.com

Telephone: +44 (0) 1527 65858